Integrated stretch-bending roof luggage rack for new energy automobile and forming process thereof

A new energy vehicle and molding process technology, which is applied to vehicle parts, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problem of reducing the service life of the roof rack, the aesthetics of the whole vehicle, easy wear and corrosion, and poor installation and disassembly. Convenience and other issues, to achieve the effect of beautiful appearance, improved load strength and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

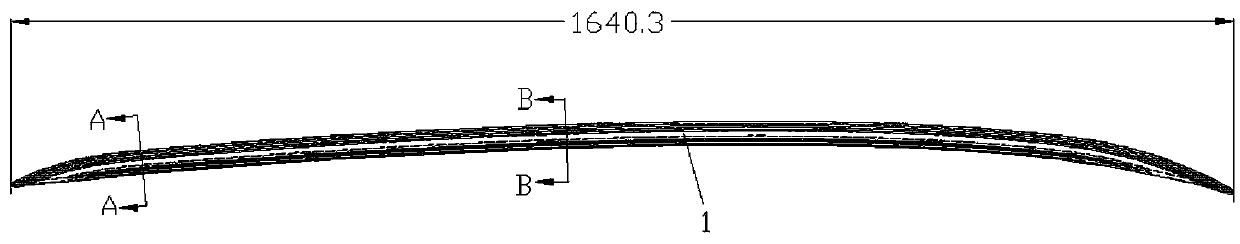

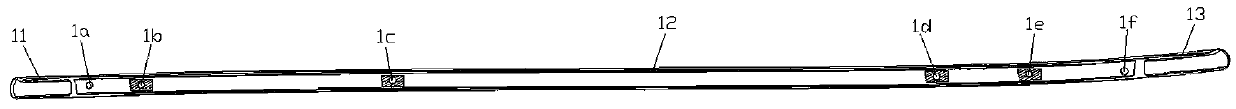

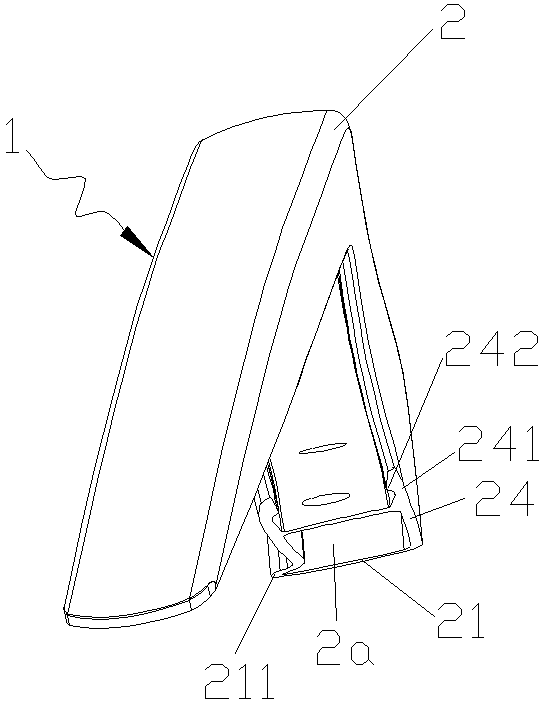

[0044] Figures 1 to 5 It is a structural representation of the present invention.

[0045] The reference signs are: luggage rack body 1, first hole 1a, second hole 1b, third hole 1c, fourth hole 1d, fifth hole 1e, sixth hole 1f, front support section 11, main body rod section 12. Rear support section 13, aluminum alloy profile rod 2, hollow cavity 2a, assembly cavity 2b, top panel 21, arc-shaped protrusion 211, left panel 22, left lower extension 221, left buckle 222, bottom panel 23 , the right panel 24 , the lower right extension 241 , and the right buckle 242 .

[0046] The roof luggage rack is a special device installed longitudinally on the left and right sides of the roof surface for placing articles. The roof luggage rack in the prior art is usually assembled from multiple parts, which not only causes the roof luggage rack to Disasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com