Microwave plasma diamond growth equipment and application method thereof

A technology of microwave plasma and application method, applied in the field of ion diamond growth equipment, can solve the problems of inability to grow single crystal diamond, low power density of hot wire, and high energy consumption of equipment, and achieve low cost, improved energy density, and high energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

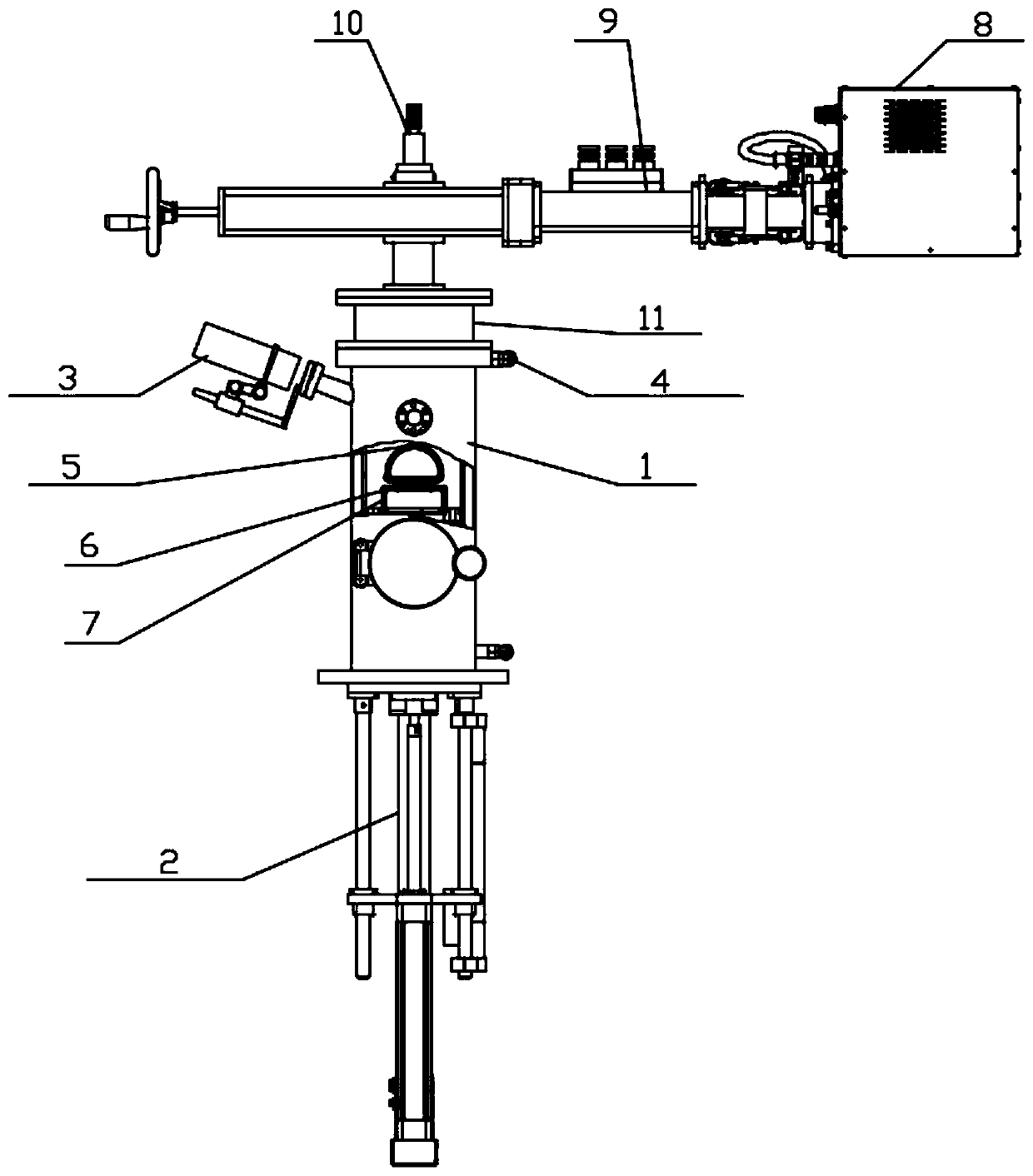

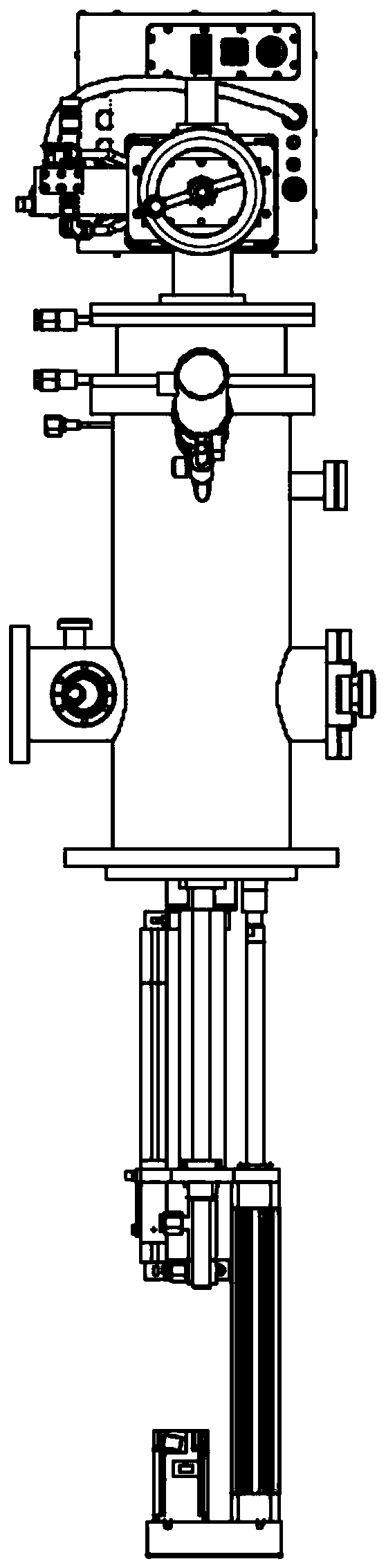

[0030] Such as figure 1 with figure 2 As shown, 1. A microwave plasma diamond growth equipment provided by the present invention includes a coupling cavity 1 with an opening at the top, a base lifting mechanism 2 at the bottom of the coupling cavity 1, and a base lifting mechanism 2 on the coupling cavity 1. There is a process gas inlet port 4, a base 7 is arranged in the coupling chamber 1, a substrate 6 is placed on the base 7, it is characterized in that a microwave device is arranged above the coupling chamber 1, and the microwave device Comprising a microwave source 8, a waveguide 9, an antenna 10 and a connecting piece 10 with an opening at the bottom, one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com