Support telescopic type mortar centrifugal spraying device

A spraying device and telescopic technology, which is applied in the field of support telescopic mortar centrifugal spraying device, can solve the problems of plastering machinery passability limitation, building material tailings scattered and lost, complex site environment, etc., and achieve convenient access to the job site and good passage Sex and off-road performance, the effect of simplifying the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

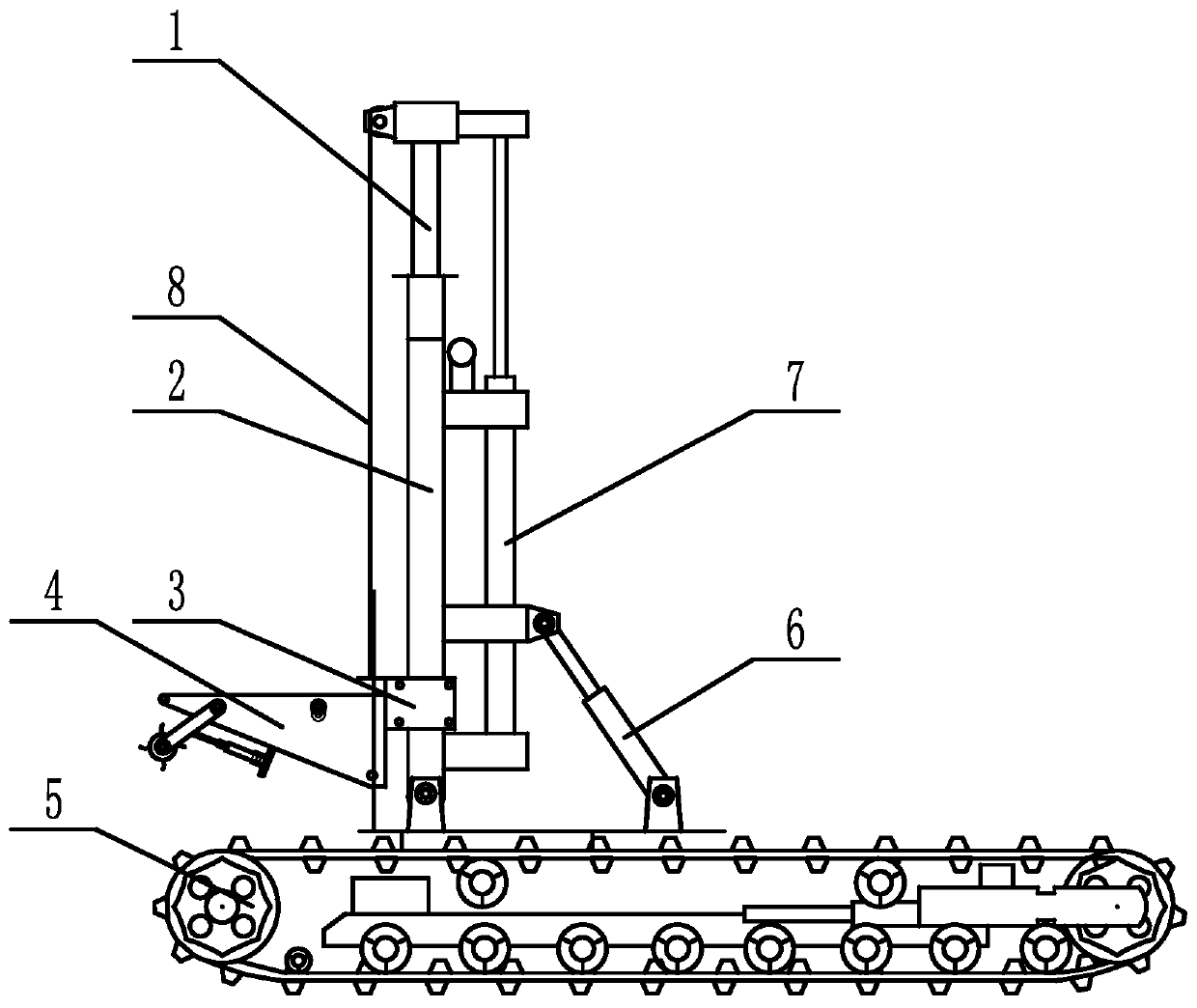

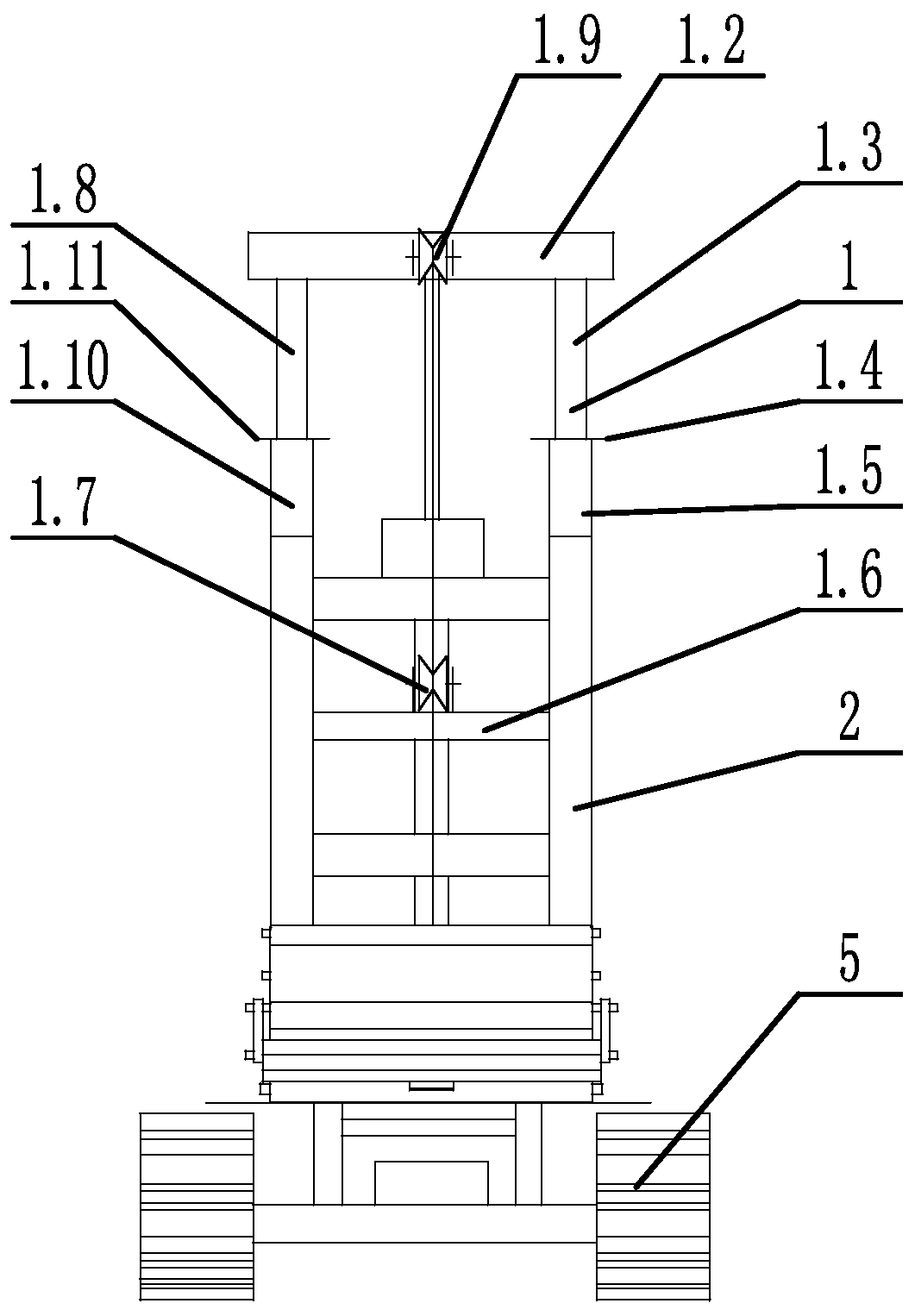

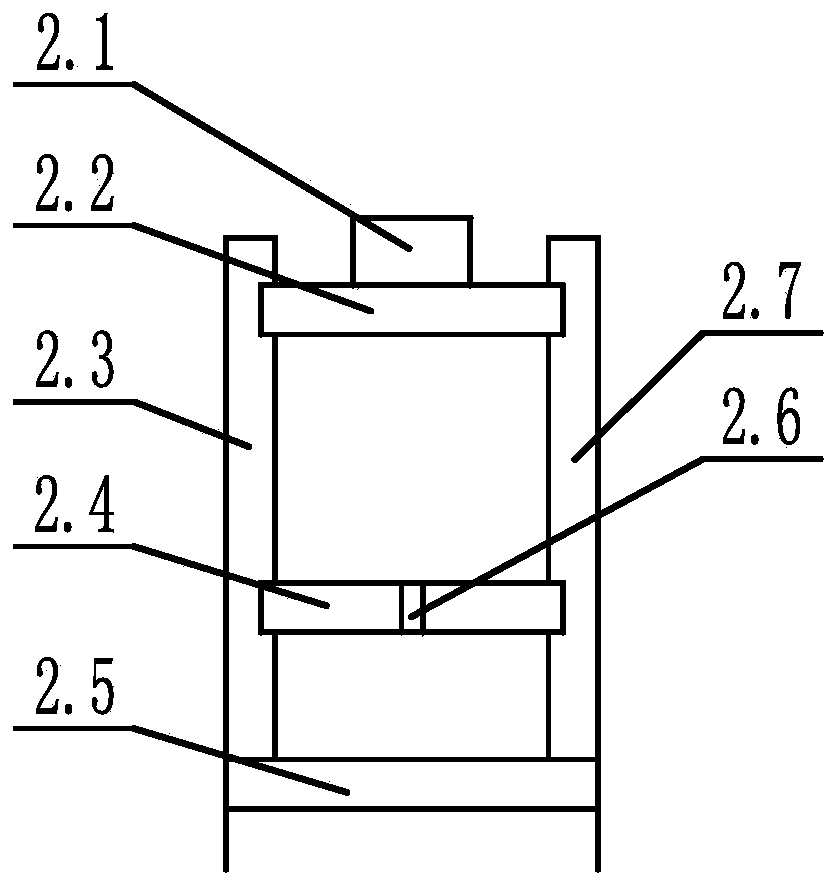

[0055] Such as Figure 1 to Figure 23 As shown, the support telescopic mortar centrifugal spraying device of the present invention includes a telescopic support, and the telescopic support includes an upper frame 1 and a lower frame 2, and the lower part of the upper frame 1 is set in the lower frame 2, and the upper frame 1 and the lower frame 2 are provided. There is a linear drive device, the fixed end of the linear drive device is connected to the bottom end of the lower frame 2, and the working end of the linear drive device is connected to the top end of the upper frame 1; the top of the upper frame 1 is provided with an upper beam pulley assembly 1.9, and the bottom end of the upper frame 1 is provided with a lower beam pulley assembly 1.7, a hydraulic winch 2.1 is provided on the top of the lower frame 2; a pole climbing runner assembly 3 is provided around the lower frame 2, and a gradient spraying direction mortar spraying device 4 is provided on one side of the climb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com