A Performance Test Bench for Phosphate Ester Oil Hydraulic Oil Tank

A technology of hydraulic oil tank and phosphate ester oil, which is applied in the direction of fluid pressure actuation system testing, fluid pressure actuation device, servo meter circuit, etc. It can solve the problems of few types of experiments and weak self-cleaning ability of oil, and achieve the degree of automation High performance, complete test parameters and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

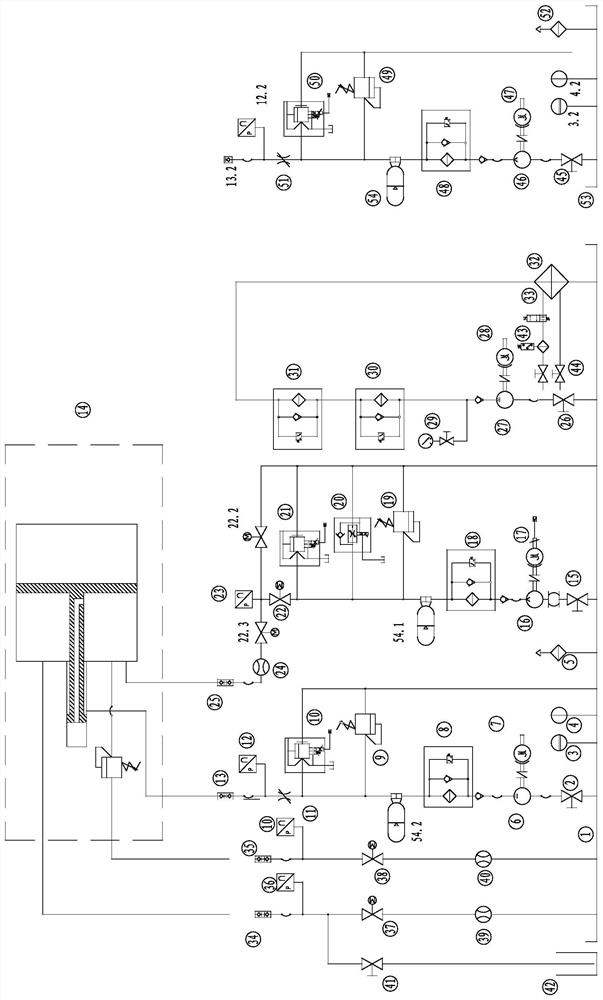

[0028] The oil tank hydraulic performance test bench is composed of three parts: hydraulic system, measurement and control system and bench body.

[0029] The hydraulic system can be applied to low-pressure system, high-pressure system, impulse cylinder system and pressure-resistant system, and can be tested independently. The hydraulic system of the fuel tank performance test bench is an open system, and the hydraulic system can realize internal leakage test, pressure test, static friction test, no-load and full-load work test, volume test, endurance life test, test of pressure relief valve work, low-pressure safety valve performance test. The hydraulic system has self-cleaning function. The oil inlet and outlet of the oil tank adopt a universal adapter, which can directly connect the oil inlet of the test bench to the oil return port, and the longest pipeline can be self-cleaned. Multiple exhaust valves are installed in the hydraulic system to facilitate the discharge of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com