Low-temperature liquid treatment device and construction method thereof

A processing device and low-temperature liquid technology, applied in construction, water supply devices, household refrigeration devices, etc., can solve the problems of small processing flow, risk of explosion, high cost, etc., and achieve the effect of improving stability and reducing the probability of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

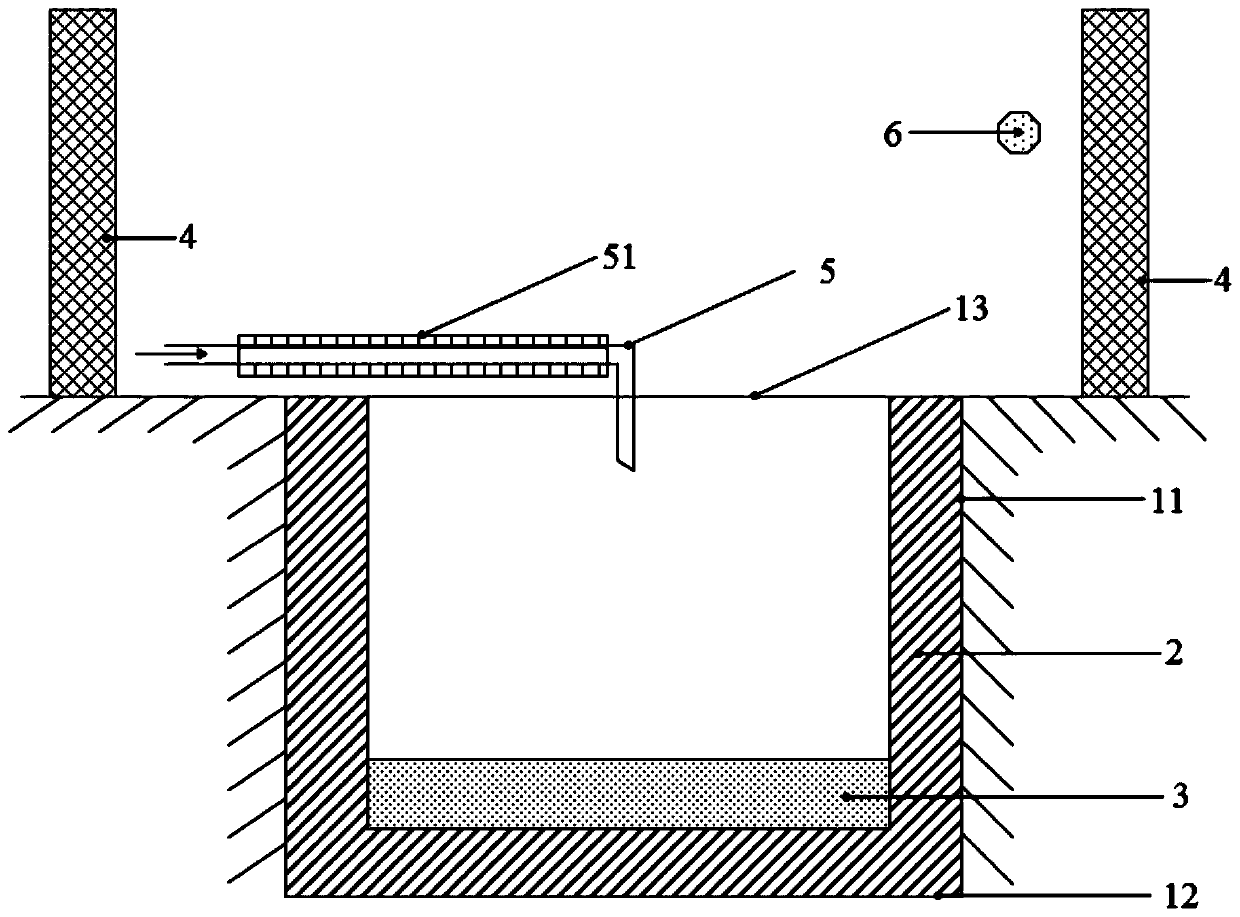

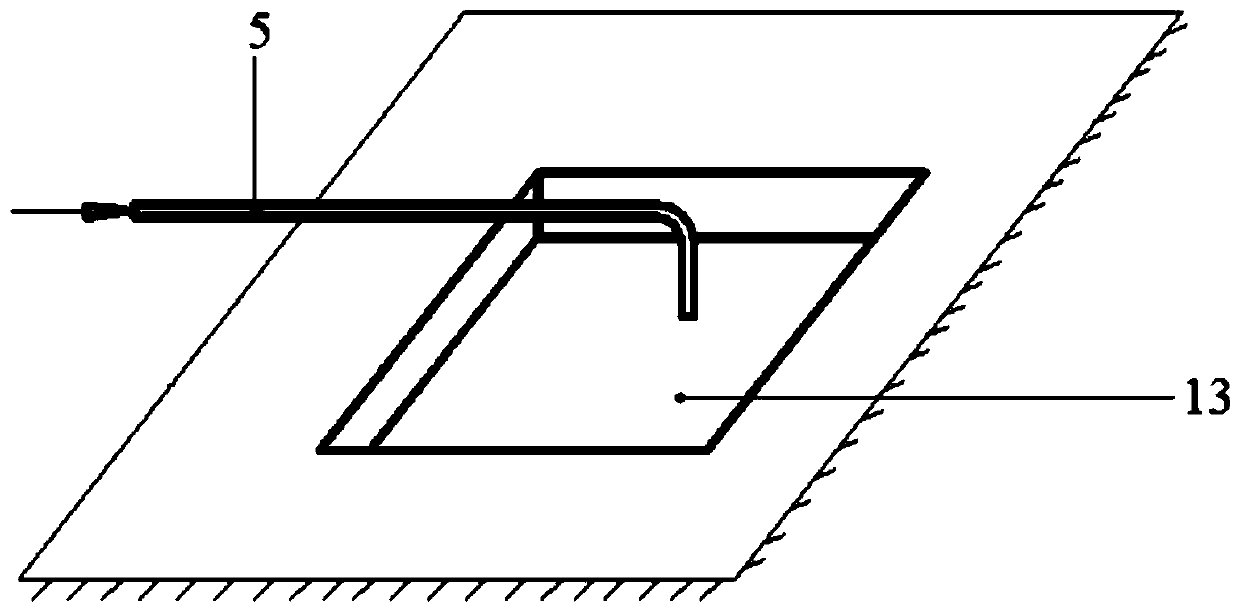

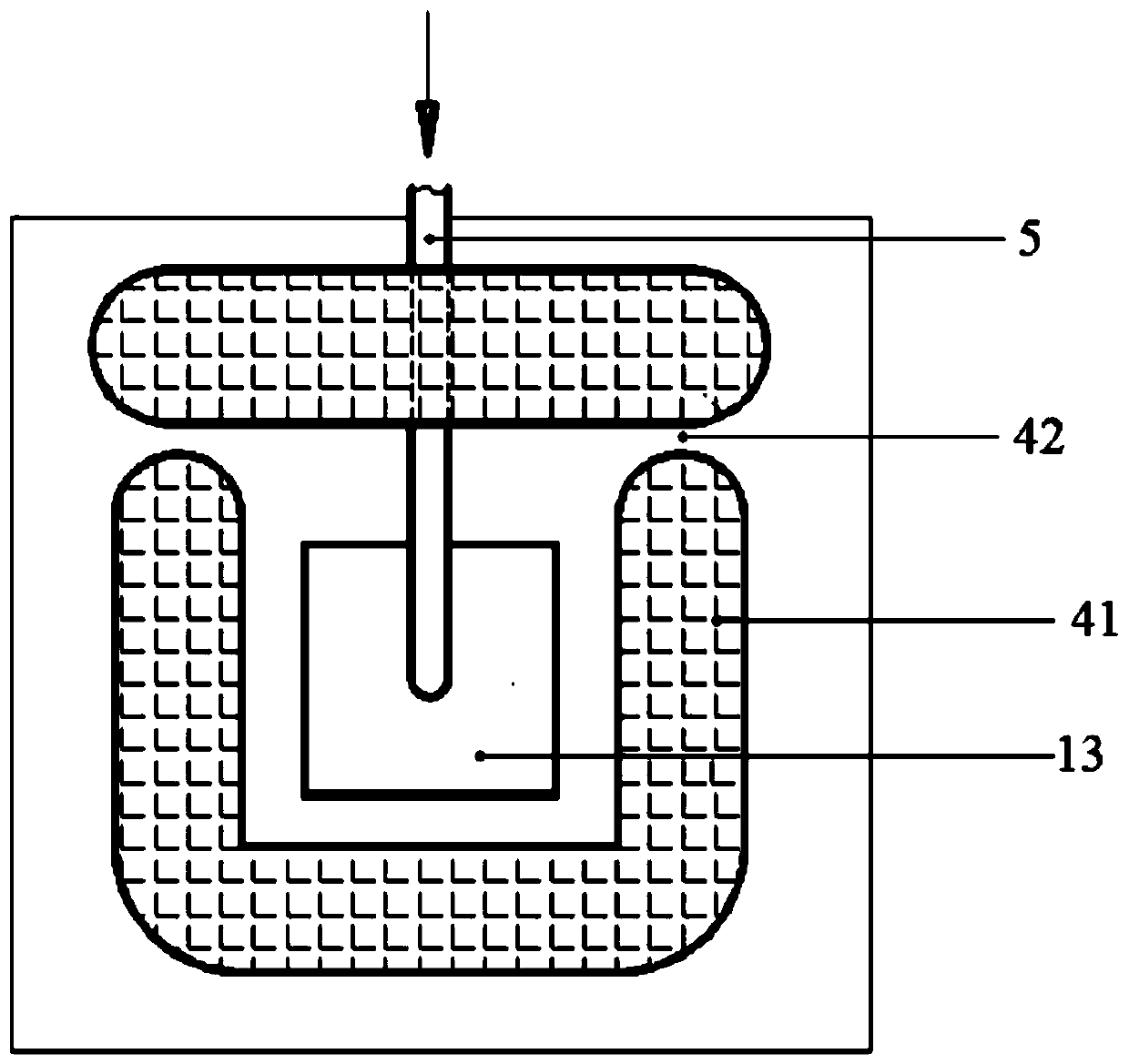

[0050] This embodiment provides a cryogenic liquid processing device, such as figure 1 - image 3 As shown, it includes accommodating structure 1, reinforcement structure 2, protective structure 4 and heat conduction structure 3, such as figure 1 As shown, the accommodating structure 1 has an accommodating inner cavity formed below the ground for accommodating liquid, and a first opening 13 communicating the accommodating inner cavity with the outside world. A reinforcing structure 2 for reinforcing the inner cavity of the containing structure 1 is provided on the inner wall surface of the containing structure 1 , and a heat conducting structure 3 is provided on the reinforcing structure 2 located on the bottom wall surface 12 of the containing structure 1 . A protective structure 4 is provided around the first opening 13 of the accommodating structure 1 , and the protective structure 4 has a protective body 41 extending along the direction of the accommodating structure 1 . ...

Embodiment 2

[0059] This embodiment provides a construction method for the low-temperature liquid processing device in Embodiment 1, including the following steps:

[0060] S1, excavating the ground at the selected location, forming a storage cavity for containing liquid under the ground, and a first opening 13 connecting the storage cavity with the outside world, and obtaining a storage structure 1;

[0061] Specifically, choose a location far away from the building crowd, and design the size and depth of the required accommodation cavity in combination with the local wind speed, and excavate at a location with low wind speed and low lateral volatility of gas to obtain an underground pit as the storage structure 1. The inner cavity of the pit is used as the accommodating inner cavity, and the opening on the top of the pit is used as the first opening 13 .

[0062] S2, pouring reinforcement materials on the inner wall surface of the accommodation structure 1 to form a reinforcement structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com