Mechanical seal detection device and flushing detection process

A technology for mechanical seals and detection devices, which is used in measurement devices, fluid tightness testing, and machine/structural component testing. status, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

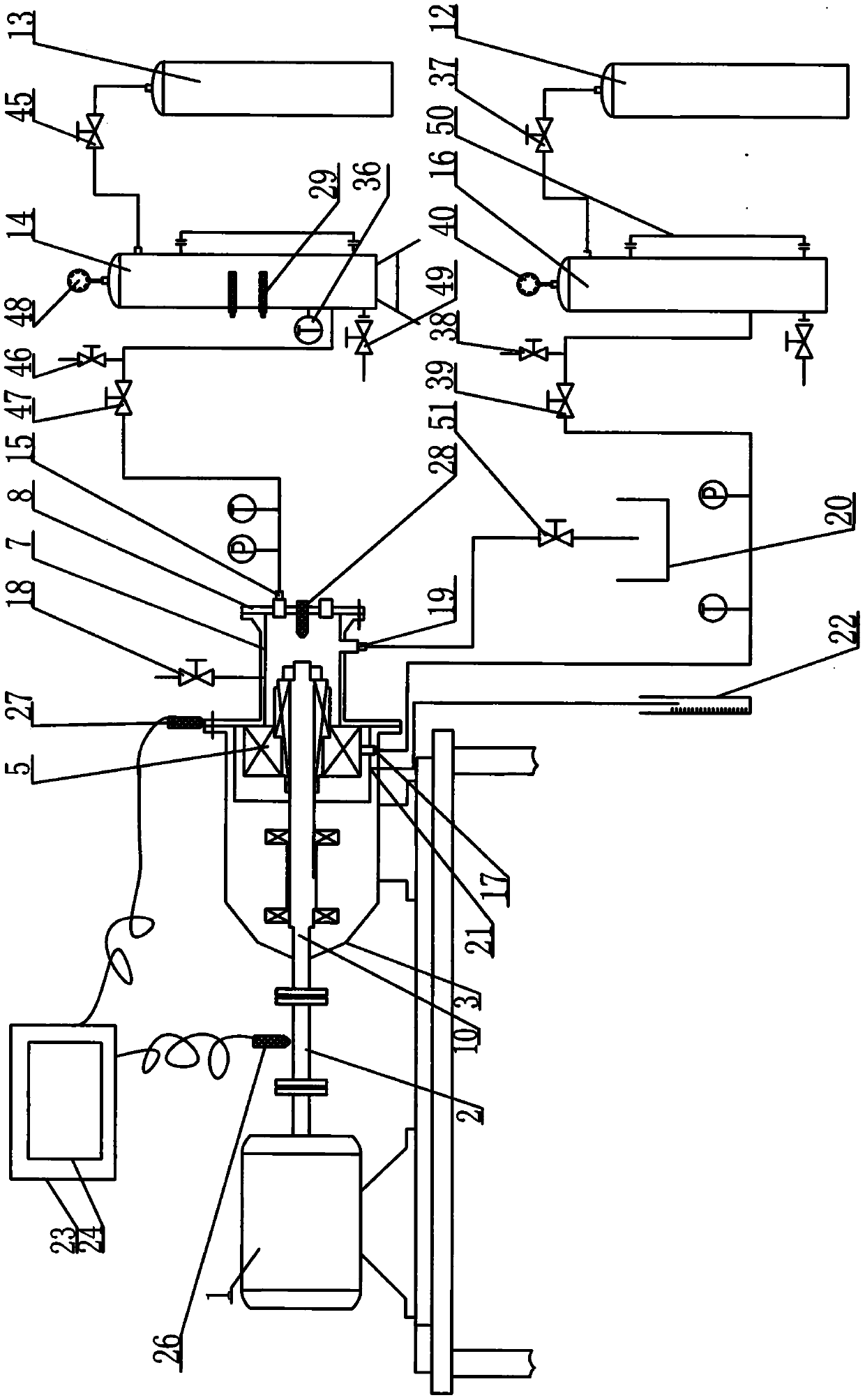

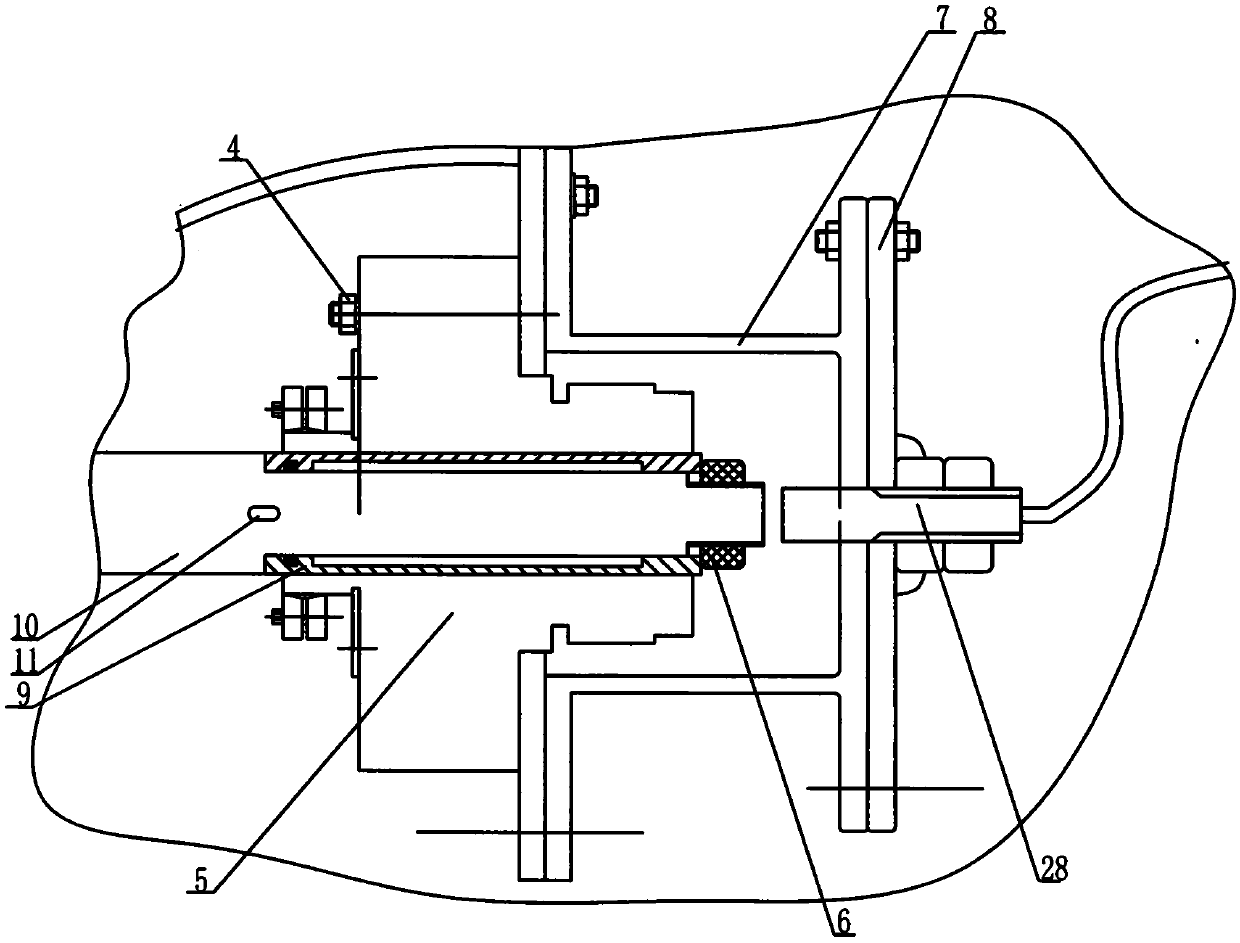

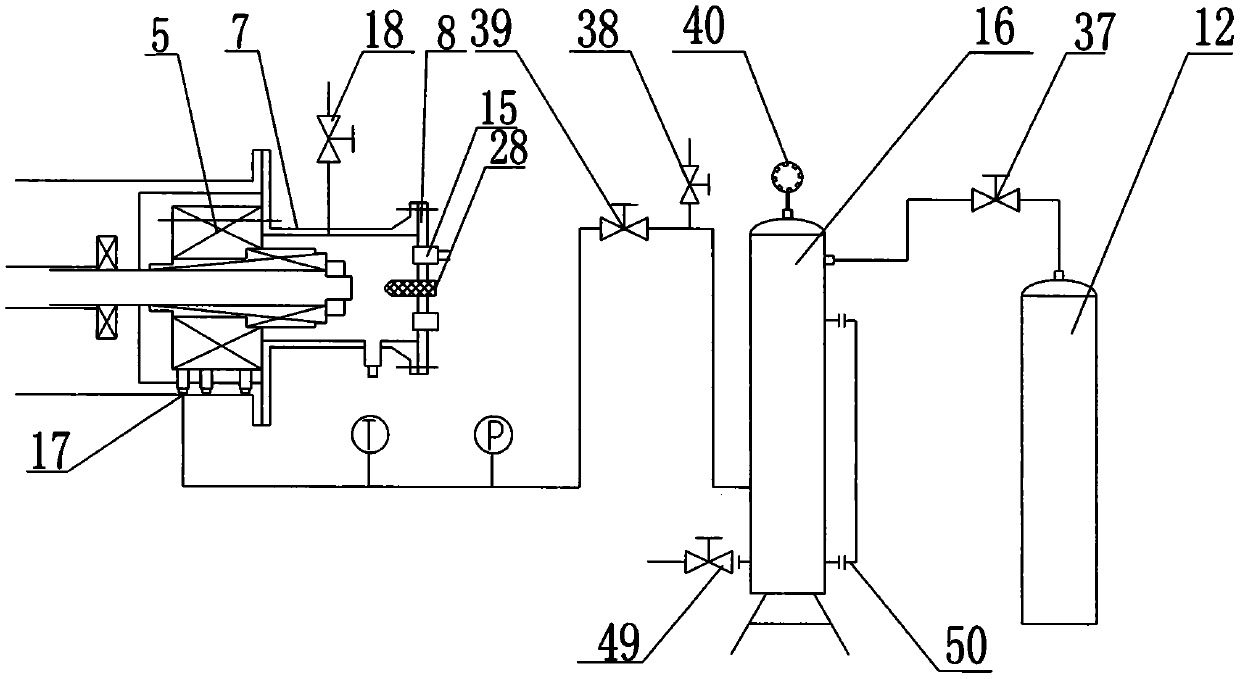

[0101] A mechanical seal detection device, including a mechanical structure part, a detection part and a control part, a, the mechanical structure part includes a main motor 1, a frequency converter 35 installed on the main motor 1, the main shaft of the main motor 1 is connected to the main motor through a shaft coupling 2 The pump shaft 10 set in the pump bracket 3 is connected, one side of the pump bracket 3 is connected with the pump casing 7 through the pump body bolts, the outer side of the pump casing 7 is provided with an end cover 8, and the pump shaft 10 in the pump bracket 3 The pump shaft 10 is connected with the shaft sleeve 9 through the key 11, and the end of the pump shaft 10 is provided with a lock nut 6 matching with the shaft sleeve 9. The shaft sleeve 9 is equipped with the rotating part of the mechanical seal 5. Part of it is connected with the pump casing 7 through the mechanical seal bolt 4, and the rotating part of the mechanical seal 5 is compatible wit...

Embodiment 2

[0116] This embodiment is the same as Embodiment 1, the difference is only that: in step 7, when the vibration value detected by the vibration sensor 27 is 1.1 mm / s, and the displacement value detected by the displacement sensor 28 is 0.04 mm, the mechanical seal 5 is judged as unqualified; Since it is judged that the mechanical seal 5 is unqualified, step 8 is cancelled.

Embodiment 3

[0118] This embodiment is the same as Embodiment 1, the difference is only that: in step 7, when the vibration value detected by the vibration sensor 27 is 1.1 mm / s, and the displacement value detected by the displacement sensor 28 is 0.02 mm, the mechanical seal 5 is determined to be unqualified; Since it is judged that the mechanical seal 5 is unqualified, step 8 is cancelled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com