Method for testing heat-conducting property of irregular sample

A technology of thermal conductivity and testing method, applied in the direction of material thermal conductivity, material thermal development, etc., can solve problems such as uneven material, irregular shape, etc., achieve the effect of increasing sensitivity, improving the nature of inverse problems, and avoiding multiple solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

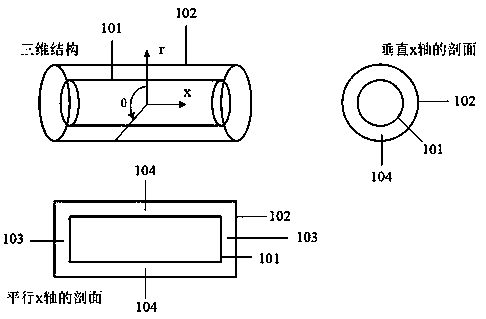

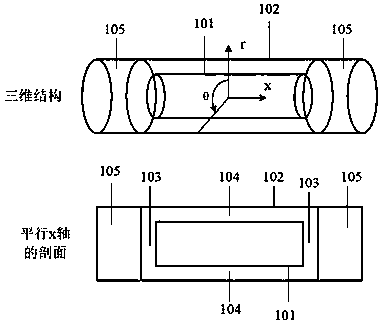

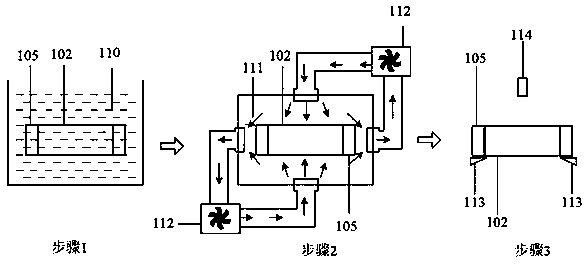

[0031] In this embodiment, the test object is a cylindrical lithium battery cell with a metal shell, and its structure is as follows: figure 1 As shown, it includes a cylindrical winding core 101 and a cylindrical metal shell 102, both of which can conduct heat transfer on the end surface 103 and the cylindrical surface 104; wherein the end surface 103 generally has a larger air gap, and the equivalent interface contact thermal resistance is larger; the cylindrical The air gap on the surface 104 is smaller, the contact is better, and the equivalent interface contact thermal resistance is smaller. The thermal conductivity of the winding core 101 is described by two parameters, the axial thermal conductivity ka and the radial thermal conductivity kr, the equivalent contact thermal resistance of the winding core 101 and the shell 102 at the end face 103 is described by Ra, and the winding core 101 and the shell 102 are in the cylinder The equivalent thermal contact resistance of ...

Embodiment 2

[0057] In this embodiment, the test object is a square lithium battery cell with a metal shell, and the structure is as follows: Figure 4 As shown, it includes a square winding core 201 and a square metal casing 202; a rectangular coordinate system is established, wherein the X-Y plane is parallel to the pole piece of the winding core, the X axis is parallel to the long side, the Y axis is parallel to the short side, and the Z axis is perpendicular to the pole piece. sheet; the winding core 201 and the shell 202 can conduct heat transfer on six surfaces, and the two contact surfaces 203 perpendicular to the Z axis have a small contact gap, generally no more than tens of microns, and the contact thermal resistance is very small; vertical X The gap between the two contact surfaces 204 of the shaft and the two contact surfaces 205 perpendicular to the Y axis is generally large, reaching more than 0.1 mm, and the contact thermal resistance is relatively large. In thermal design, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com