Communication optical cable and photoelectric composite cable for 5G network and manufacturing method thereof

A communication optical cable and network technology, which is applied in the field of communication optical cables and optoelectronic composite cables for 5G networks and their manufacturing, can solve the problems of optical fiber breakage, increased cost, communication interruption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

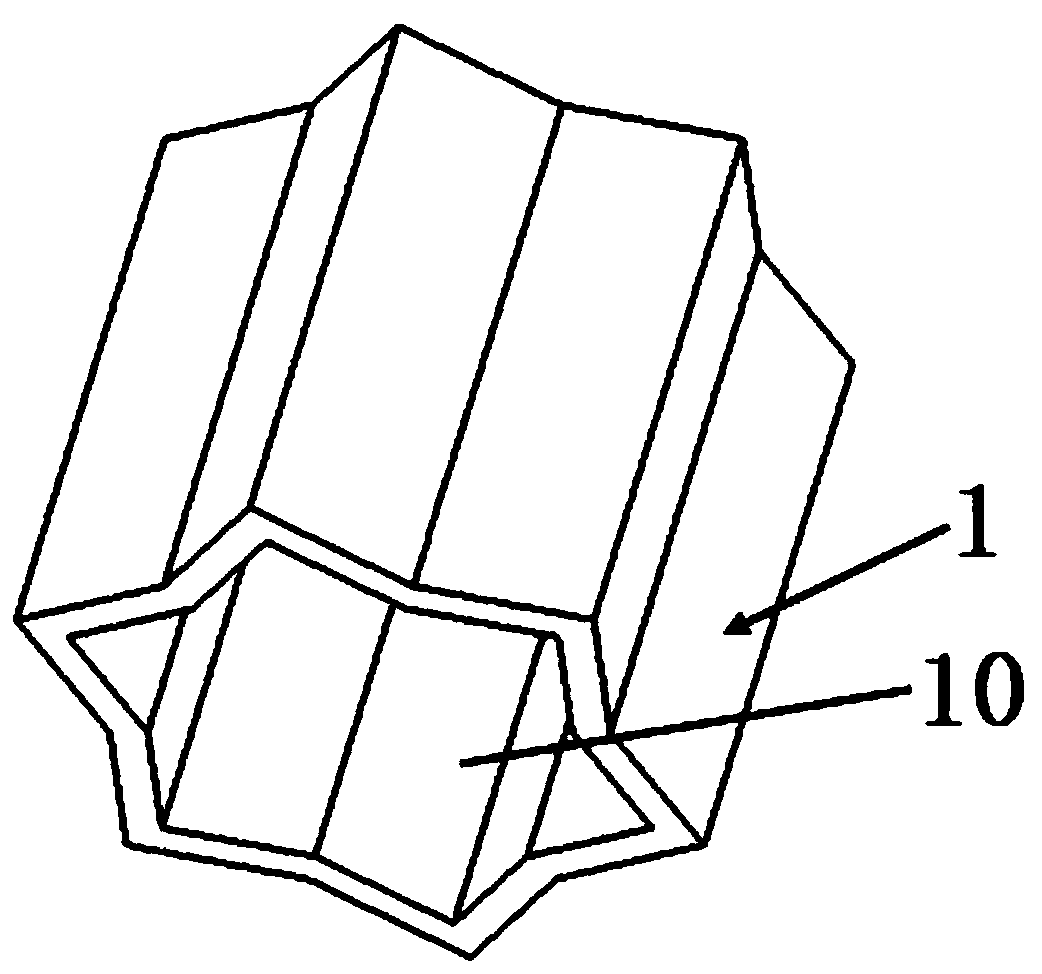

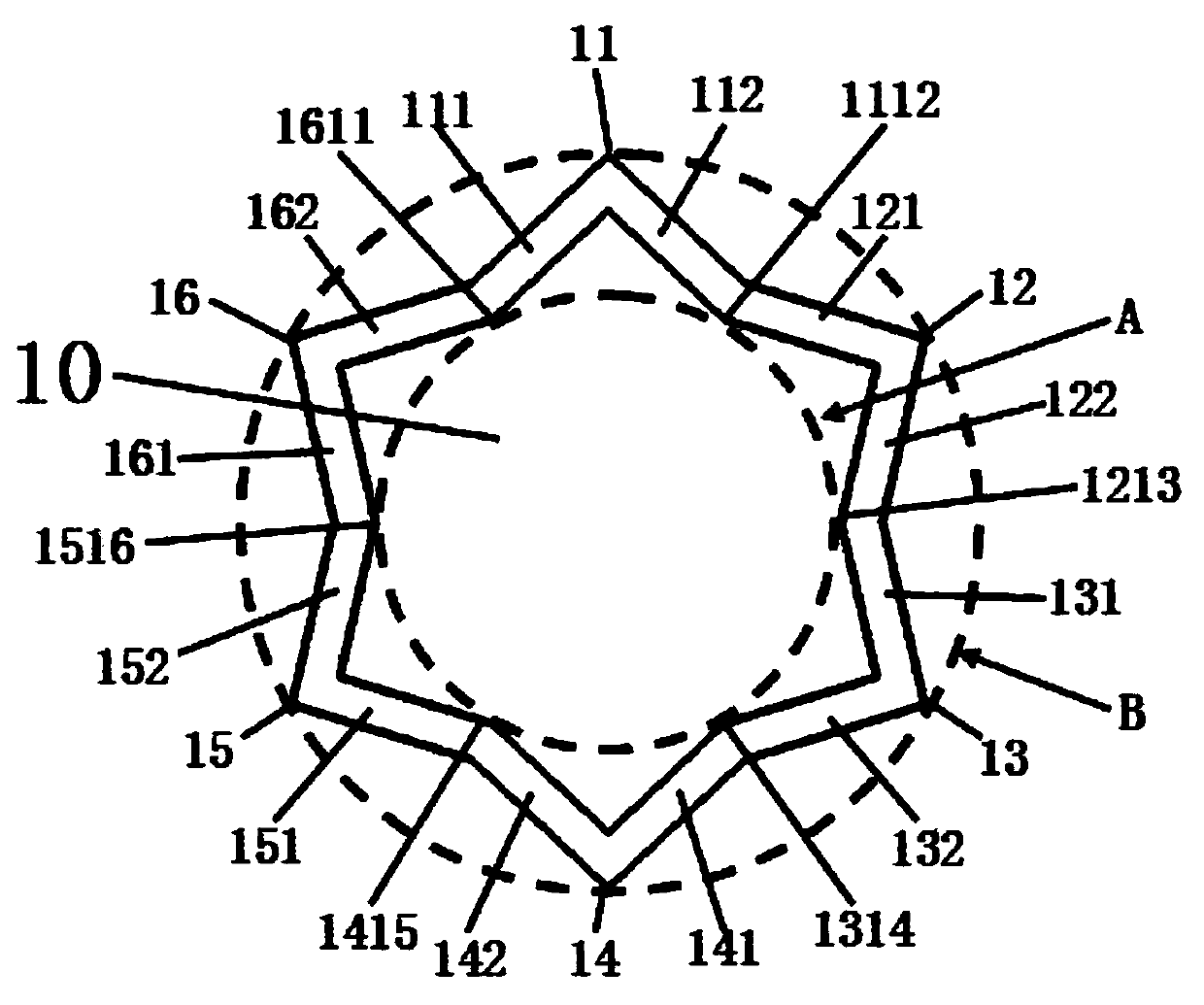

[0060] please see Figure 1 to Figure 4 ,and Figure 5 with Image 6, a communication optical cable for a 5G network, which has a plurality of outer communication components 3, a protective layer 4, a sheath layer 5 located outside the protective layer, an inner communication component 6, and a filling component 7, and the communication component 3 has a photoconductor 31 inside, The inner communication part 6 has a light guide 61 inside, and it is characterized in that there is an outer sleeve 1 and an inner sleeve 2 in the communication optical cable for 5G network, the outer sleeve 1 is located outside the inner sleeve 2, and the outer communication part 3 is located in the outer sleeve 1 and the inner casing 2, the protective layer 4 covers the outer casing 1, the filling part 7 is located in the gap formed by the protective layer 4 and the outer casing 1, and the inner communication part 6 is located in the inner casing 2; the outer casing 1 consists of the first side w...

Embodiment 2

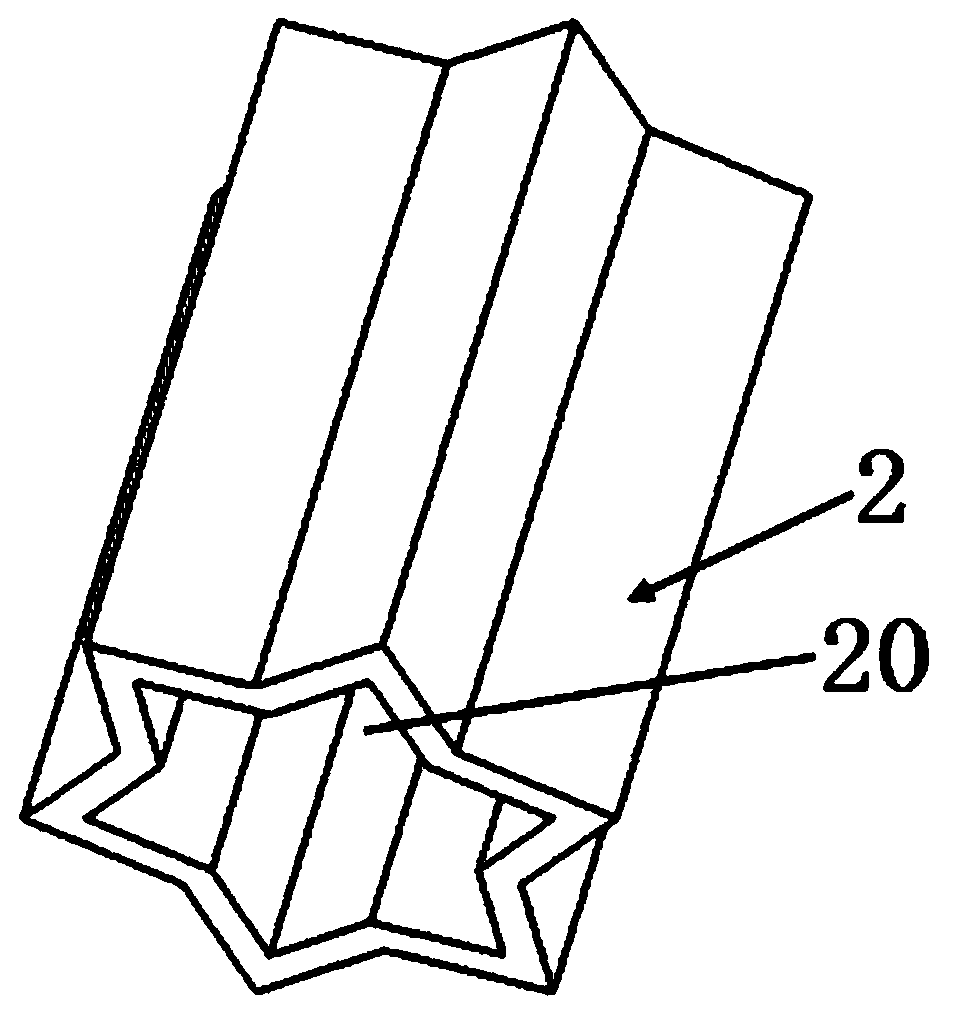

[0063] please see Figure 7 to Figure 8 , and refer to Figure 1 to Figure 6 , a photoelectric composite cable for a 5G network, which is basically the same as the implementation example 1, except that an insulated wire 8 is also provided in the inner sleeve cavity 20 outside the inner communication component 6 .

Embodiment 3

[0065] please see Figure 9 to Figure 10 , and refer to Figure 1 to Figure 8 , a photoelectric composite cable for a 5G network, which is basically the same as the second implementation example, except that the outer communication part is replaced by an insulating layer 9, and the insulating layer 9 has an electrical conductor 91 inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com