Method for improving buckling deformation of automobile headlight mask

A technology for automotive headlights and masks, applied in geometric CAD, computer-aided design, design optimization/simulation, etc., can solve problems such as designer discounts, warping and deformation of car headlight masks, and vehicles not reaching the design effect. Achieve the effect of improving the precision of processing technology, reducing production costs and overcoming warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

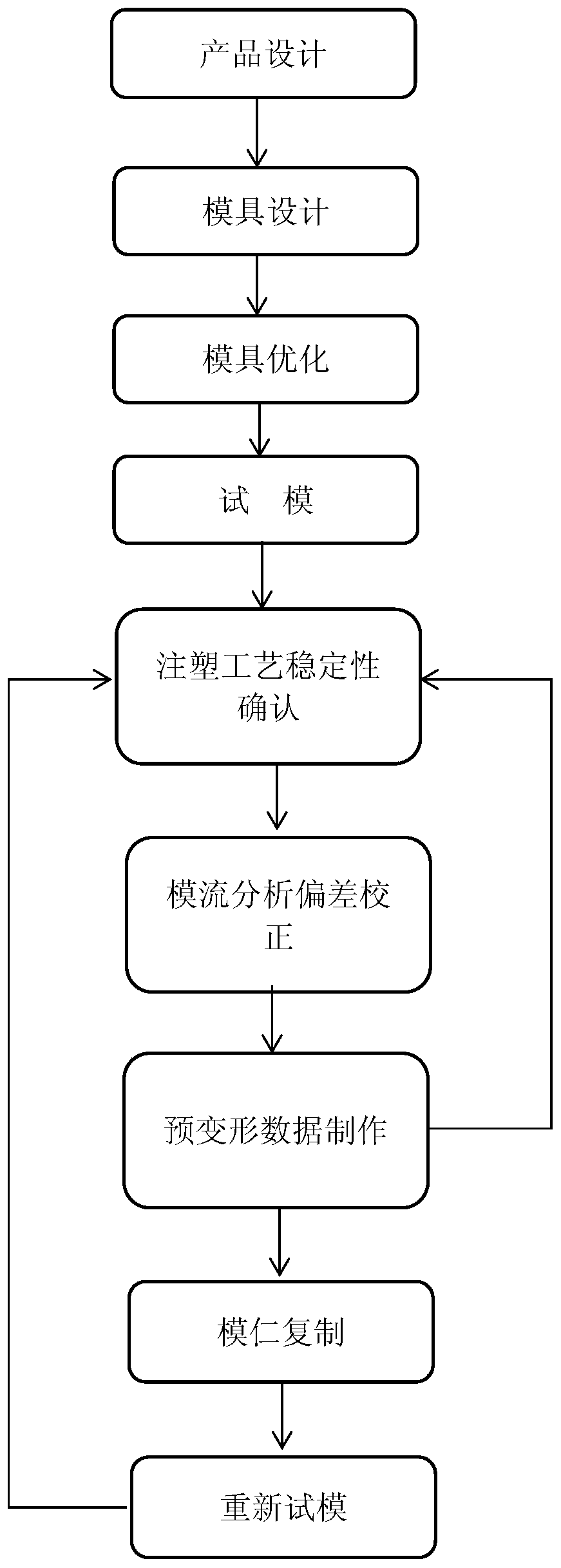

[0022] A method for improving the warpage and deformation of automobile headlight masks, the specific process is as follows figure 1 The steps shown are:

[0023] Step 1. Design the product, design the product structure, and clarify the product matching surface and requirements, so as to determine the product’s measurement point and positioning point. This step is a normal product structure design. During the design process, the product matching surface and requirements are clearly defined. Determine the measurement point of the product, the RPS point;

[0024] Step 2, design the mold, design a detachable and replaceable mold core according to the product matching surface designed in step 1, in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com