Airborne photoelectric turret mirror local heating device

A local heating, photoelectric turret technology, applied in the field of optoelectronics, can solve the problems of reducing system reliability, maintainability, low heat radiation efficiency, and improving process difficulty, and achieve reliability assurance, high heat transfer efficiency, and weight reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

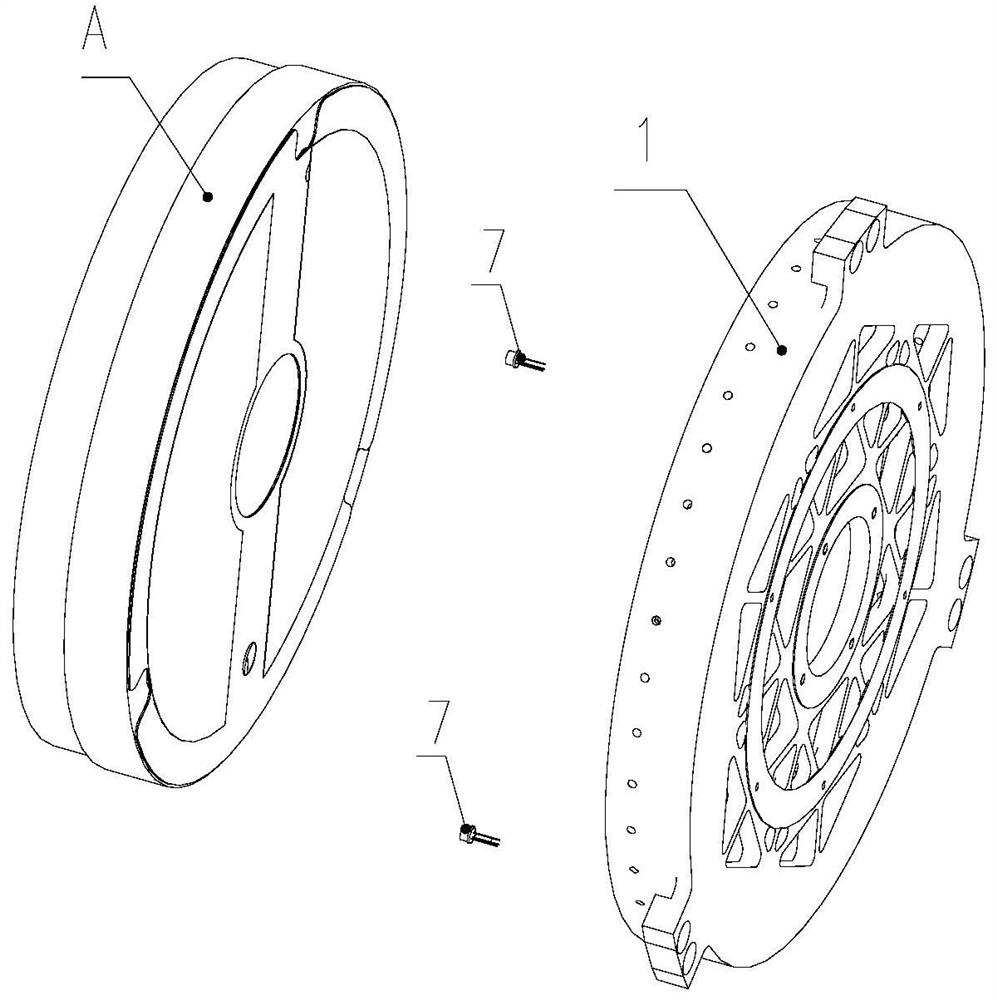

[0077] according to figure 1 As shown, this embodiment includes a mirror thermal control module A, a mirror base 1, and a heating film temperature sensor 7. The mirror thermal control module A is located inside the mirror base 1, and the heating film temperature sensor 7 is in the hollow hole of the mirror base 1. It is bonded with the mirror thermal control module A to form a local heating device for the airborne photoelectric turret mirror.

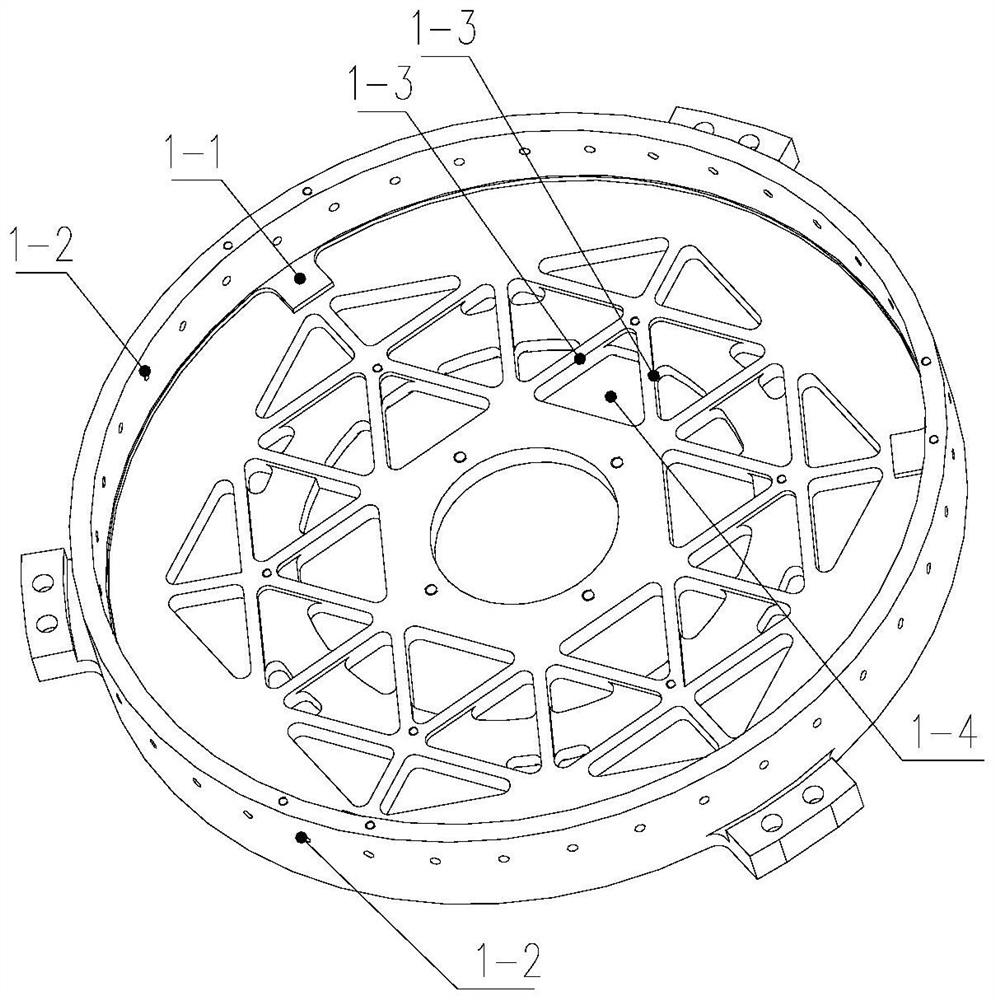

[0078] according to figure 2 As shown, the main body of the mirror base 1 is a hollow oblate cylinder. One end face of the mirror base 1 is open, and the other end face is hollowed out, forming several reinforcing ribs 1-3, and hollow holes 1-4 are formed between the reinforcing ribs 1-3; U”-shaped positioning boss 1-1, the outer edge of the positioning boss 1-1 is in contact with the inner diameter of the cylindrical surface of the mirror base 1; the cylindrical surface of the mirror base 1 is provided with a number of glue-filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com