Production method of fatty alcohol-polyoxyethylene ether triethanolamine sulfate containing amino acid groups

A technology of alcohol polyoxyethylene ether and triethanolamine salt, which is applied in chemical instruments and methods, preparation of sulfonic acid, preparation of sulfonate, etc., can solve problems such as weak degreasing ability, and achieve low production cost, simple operation, and improved The effect of degreasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of production method of fatty alcohol polyoxyethylene ether sulfate triethanolamine salt containing amino acid group, comprises the following steps:

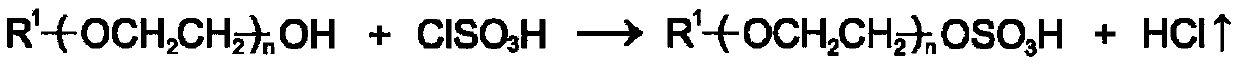

[0019] S1 Add fatty alcohol polyoxyethylene ether into the reaction container, preheat to 25-27°C, slowly add chlorosulfonic acid while stirring, the reaction time is 2.5-3.5h, and continue to vacuumize during the reaction process. The degree of vacuum is 0.5-2.5 Pa to remove the hydrochloric acid generated by the reaction. In order to completely react the fatty alcohol polyoxyethylene ether, the molar mass ratio of the fatty alcohol polyoxyethylene ether to chlorosulfonic acid is 1:1.05-1.1.

[0020] The main reaction process is as follows:

[0021]

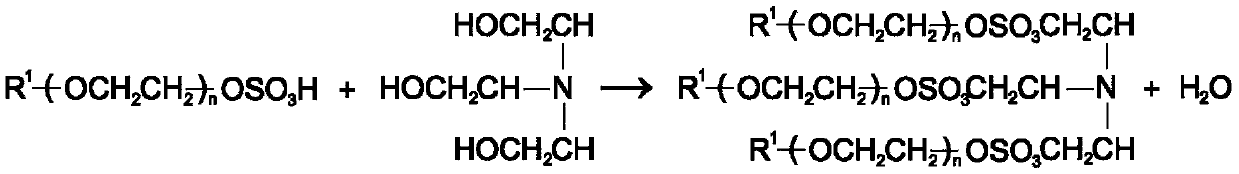

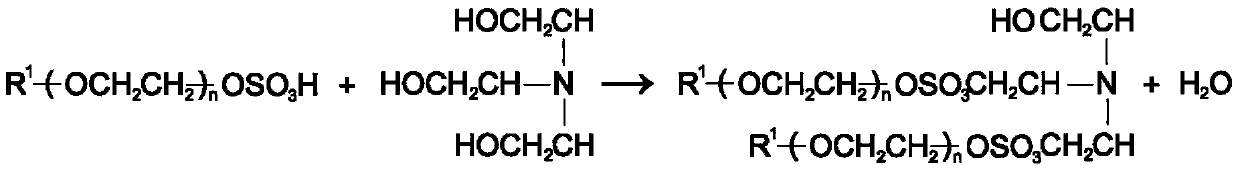

[0022] S2 Raise the temperature to 38-42°C, add 30% triethanolamine aqueous solution to carry out neutralization reaction, the reaction time is 1.5-2h, wherein, in order to introduce amino acid groups in subsequent reactions, triethanolamine and fatty alcohol poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com