Supported catalyst and preparation method thereof

A supported catalyst and catalyst carrier technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of uneven dispersion of active substances, and achieve increased Effects of interaction, increased specific surface area, low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

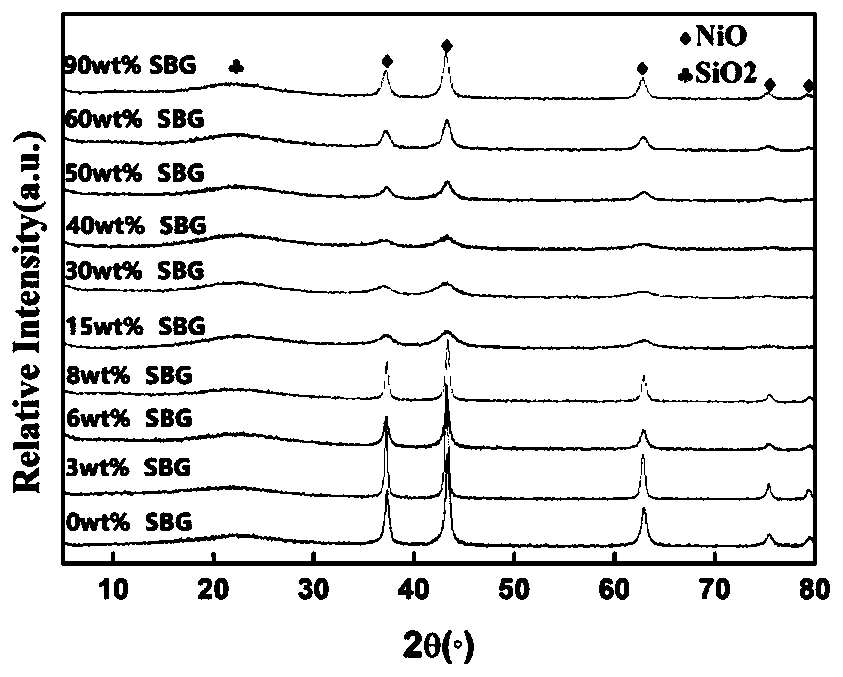

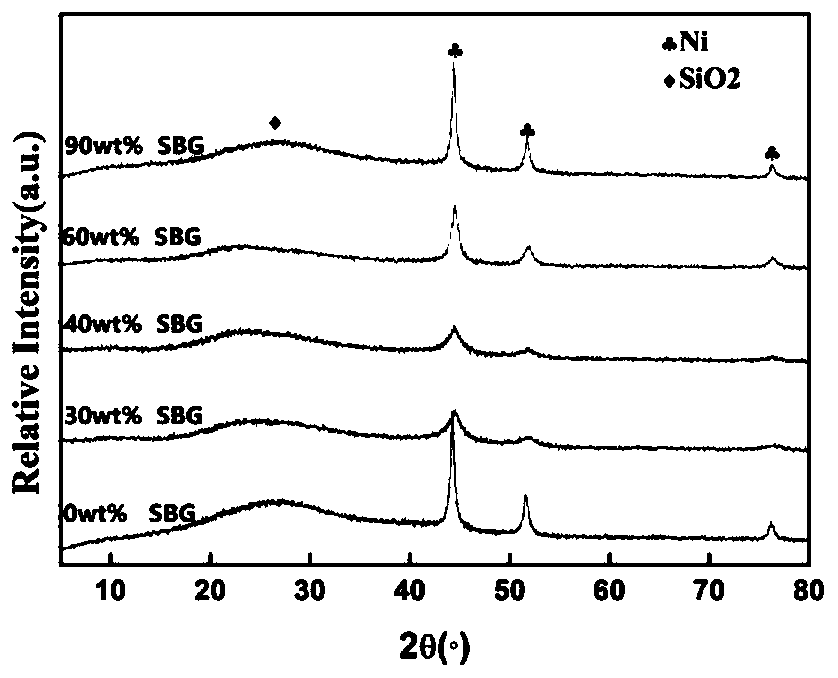

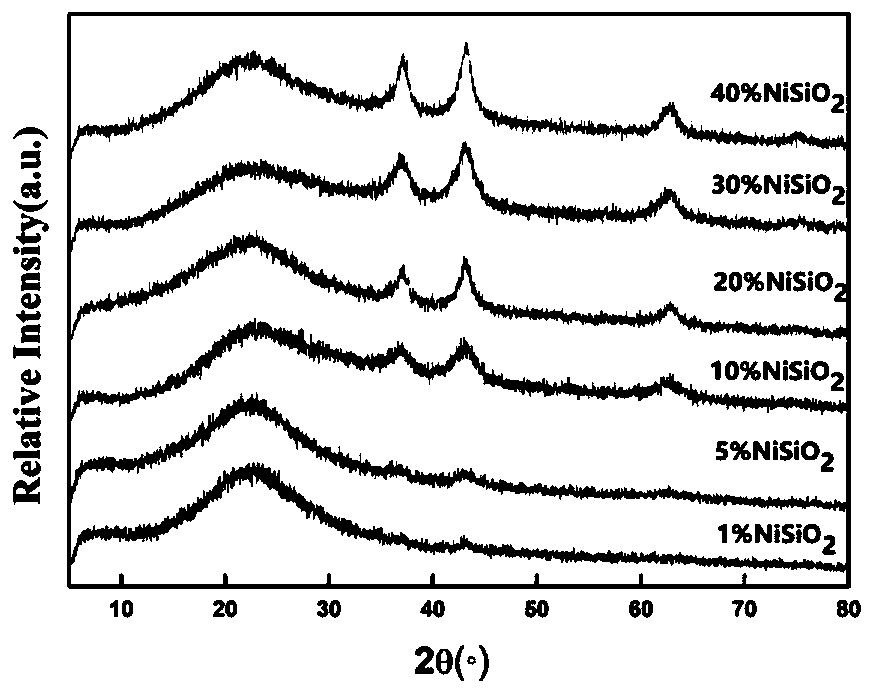

[0040] This embodiment is a supported catalyst 20% Ni-SiO 2 (30wt% safflower powder (SBG)).

[0041] Weigh 34.67g tetraethyl orthosilicate and set aside. At room temperature, add 9.9094g Ni(NO 3 ) 2 ·6H 2 O, a certain amount of ultrapure water, 3.0697g of scallop powder, stirred at 120°C for 24 hours, dried at 120°C for 24 hours, put the dried sample in a muffle furnace, calcined at 600°C for 4 hours, and the heating rate was 10°C / min , to get the supported catalyst Ni-SiO 2 , the loading amount of Ni is 20%, which is recorded as 20% Ni-SiO 2 (30 wt% SBG).

[0042] The specific surface area BET of the supported catalyst of this embodiment is 371.7825m 2 g -1 .

Embodiment 2

[0044] This embodiment is a supported catalyst 20% Ni-SiO 2 (0 wt% SBG) preparation.

[0045] The difference between the present embodiment and embodiment 1 is only that the consumption of the kale powder is 0 g.

[0046] The specific surface area BET of the supported catalyst of this embodiment is 207.4457m 2 g-1 .

Embodiment 3

[0048] This embodiment is a supported catalyst 20% Ni-SiO 2 (3 wt% SBG) preparation.

[0049] The difference between this embodiment and embodiment 1 is only that the consumption of the scallop powder is 0.3069g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com