Environment-friendly multifunctional mixing device for aerated concrete

A kind of technology of aerated concrete and mixing device, which is applied in the direction of mixing operation control device, clay preparation device, mixing operation control, etc. It can solve the problems of poor mixing degree of raw materials, cumbersome operation, and increased mixing and stirring process, etc., and achieves convenient fixing Mounting and dismantling, highly mixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

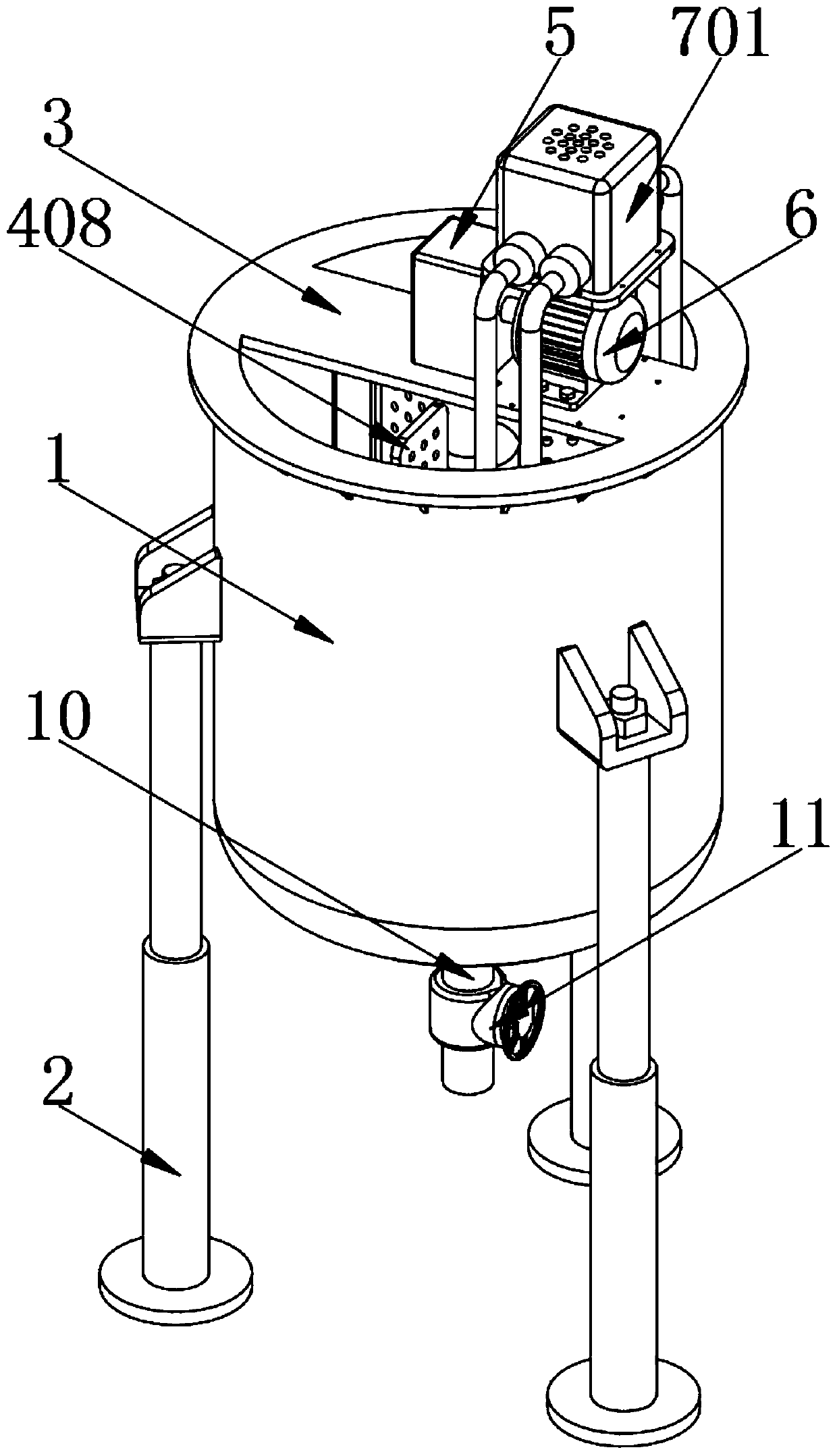

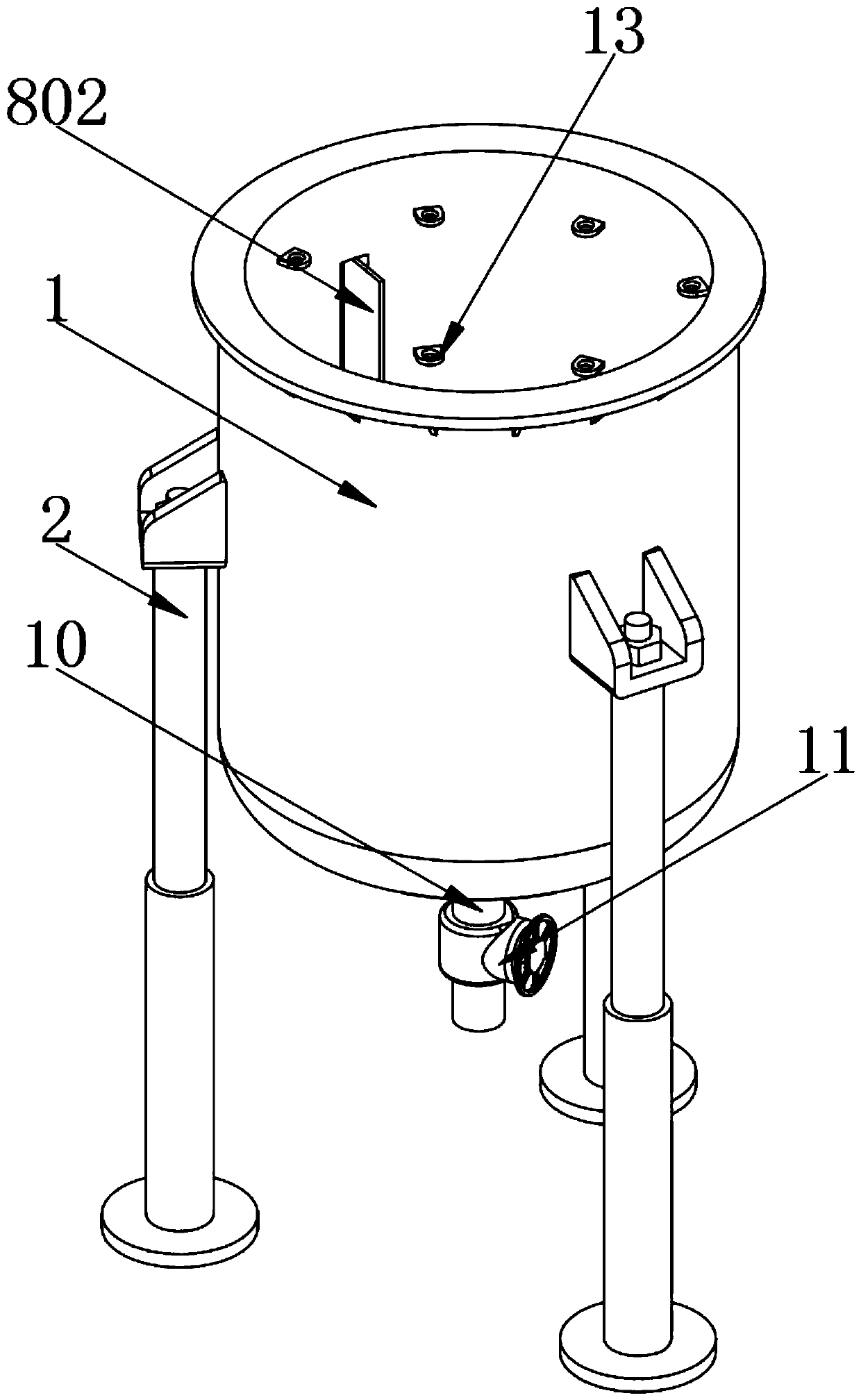

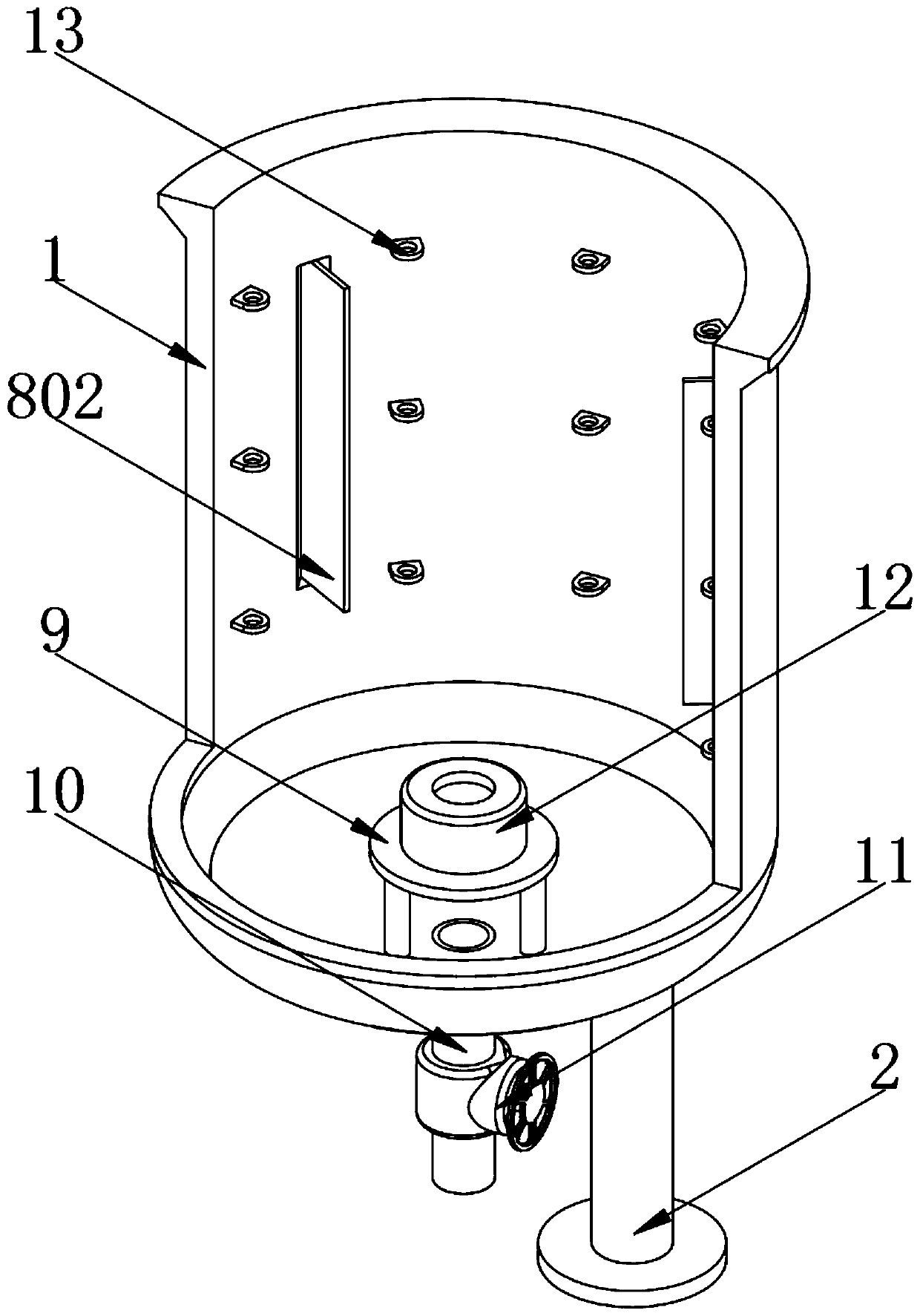

[0041] Example: such as Figure 1-6 As shown, an environment-friendly multifunctional mixing device for aerated concrete includes a mixing bucket 1, a support column 2 and a support suspension plate 3, and several support columns 2 are fixedly installed on the outer side of the mixing bucket 1, and the top of the mixing bucket 1 The middle part is fixedly installed with a support suspension plate 3, and the middle part of the support suspension plate 3 is installed with a mixing assembly 4 for stirring raw materials. One side is provided with a driving motor 6 fixed on the support suspension plate 3, the driving motor 6 is electrically connected to the power supply, and the outer side of the driving motor 6 is sealed and sleeved with a heat transfer assembly 7, which is used to dissipate the heat generated during the working process of the driving motor 6. On the one hand, the drive motor 6 can be dissipated to prolong the service life of the drive motor 6; Carry out heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com