Safety loop system and rail train

A safety loop and safety protection technology, applied to railway car body components, railway signal and safety, electric vehicles, etc., can solve problems such as low reliability and high power consumption, so as to ensure safe operation and improve service life , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further detail below through specific embodiments and accompanying drawings.

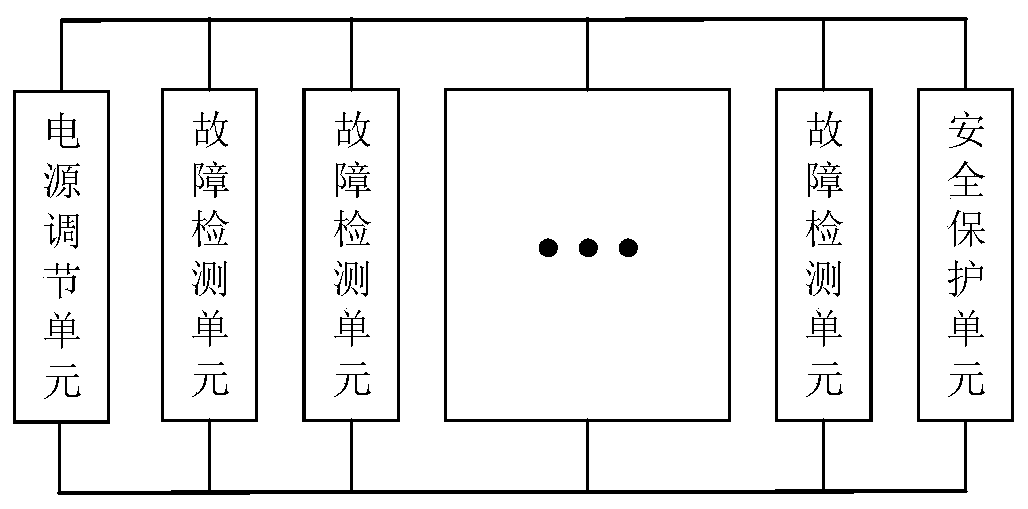

[0024] figure 1 It is a schematic structural diagram of the safety loop system in Embodiment 1 of the present application. like figure 1 As shown, the safety loop system provided in this embodiment specifically includes a power regulation unit, a fault detection unit, and a safety protection unit, wherein:

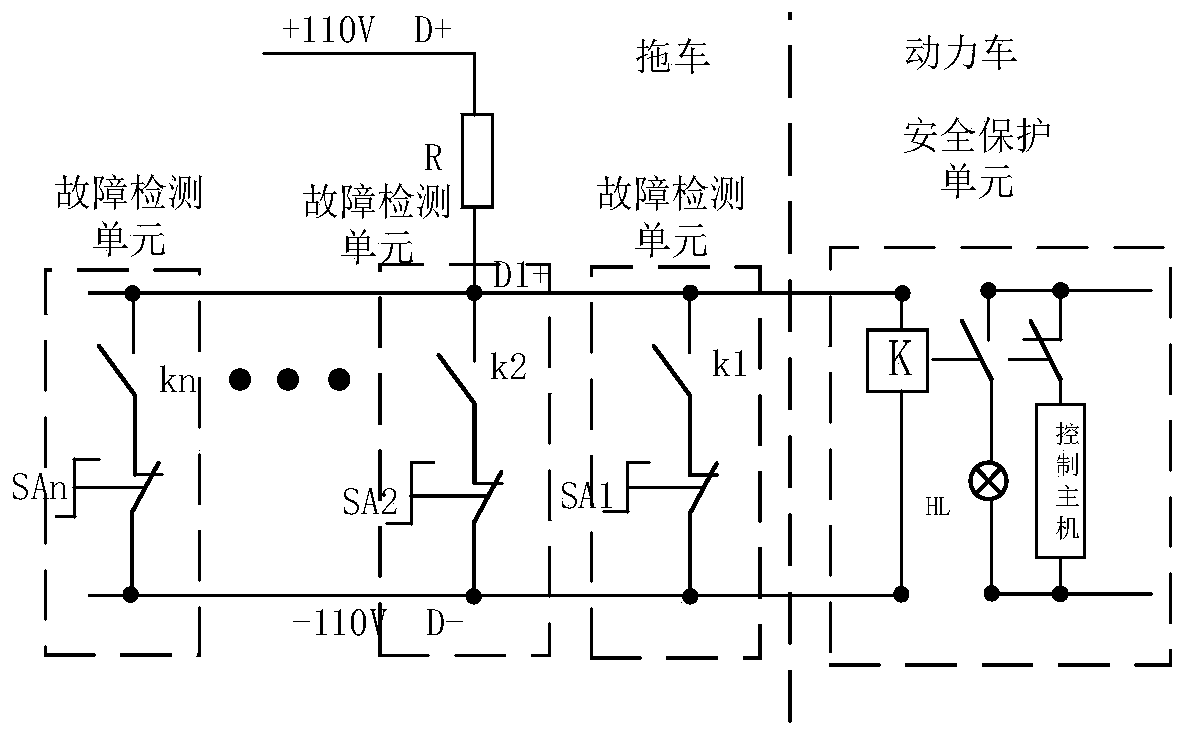

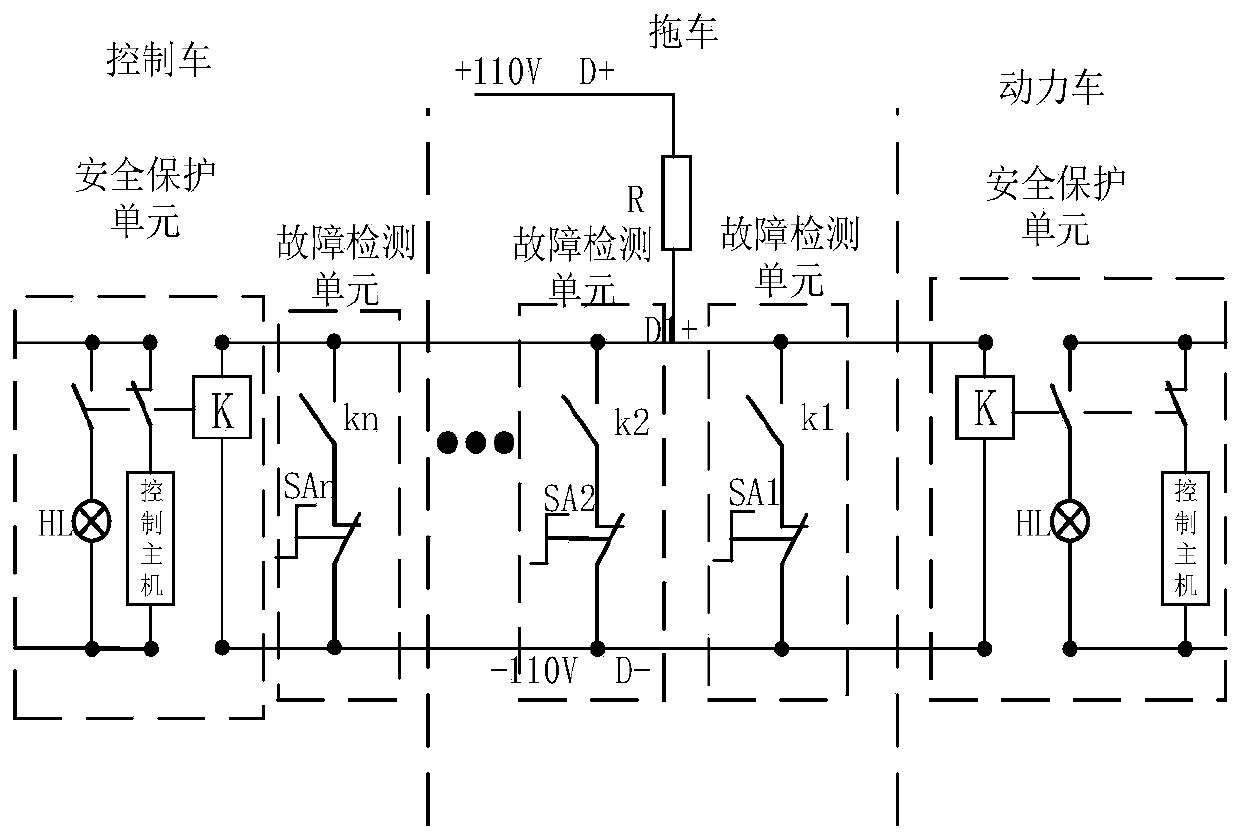

[0025] The power adjustment unit is used to supply power to the fault detection unit and the safety protection unit. The fault detection unit and the safety protection unit are connected in parallel. There are multiple fault detection units. Detection units (specifically, distributed in the compartments of the trailer and the control vehicle). The safety protection unit is arranged in the driver's room of the rail train (specifically, in the power car and the control car), and is used for alarming the driver and takin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com