Clothing hanging conveying system

A transmission system and hanging technology, which is applied to sewing tools, conveyors, transportation and packaging, etc. It can solve the problems of affecting the efficiency of garment making, the bumping of the hanger wheel, and the mismatch between the hanger wheel and the connecting track. To achieve the effect of improving clothing efficiency and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

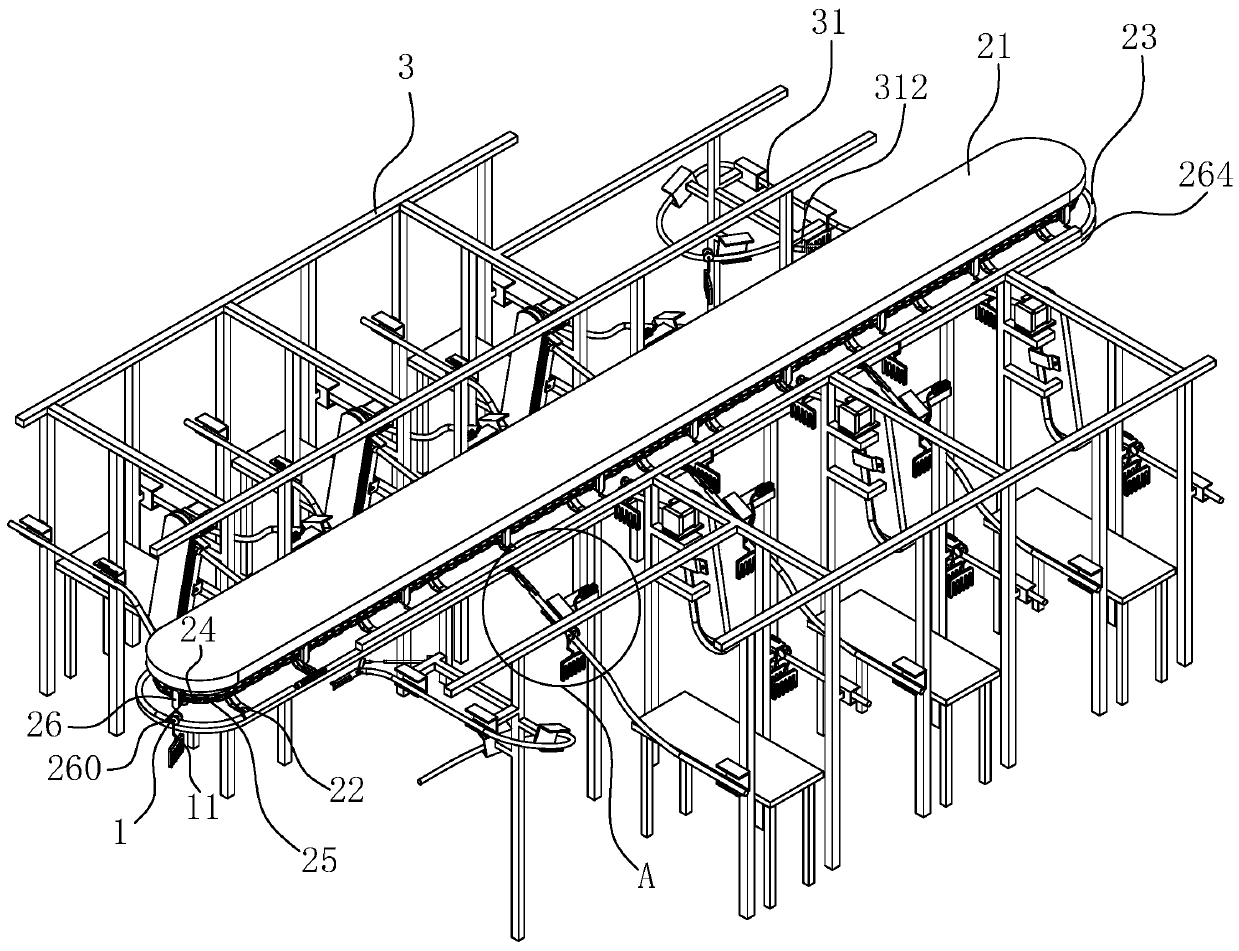

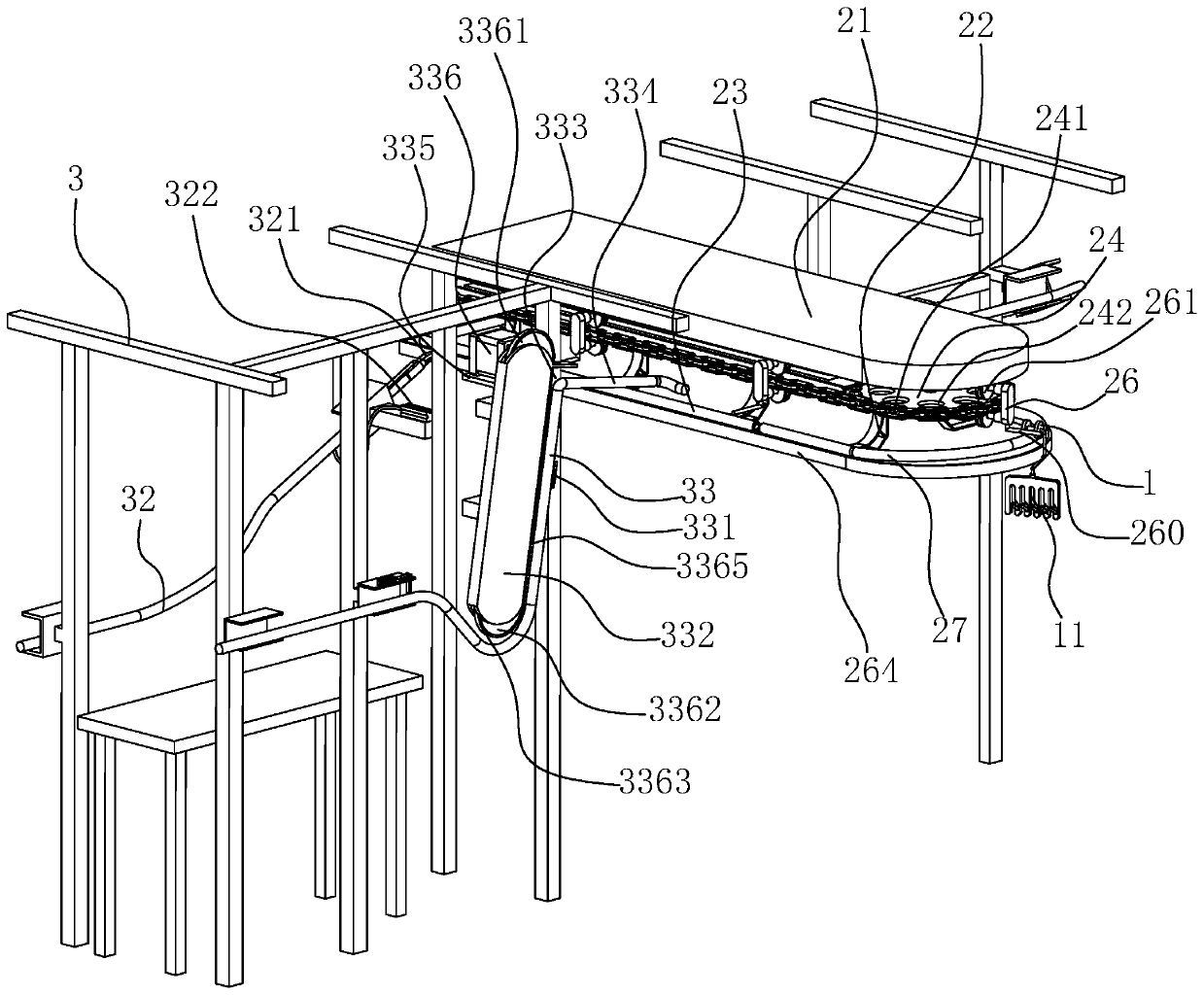

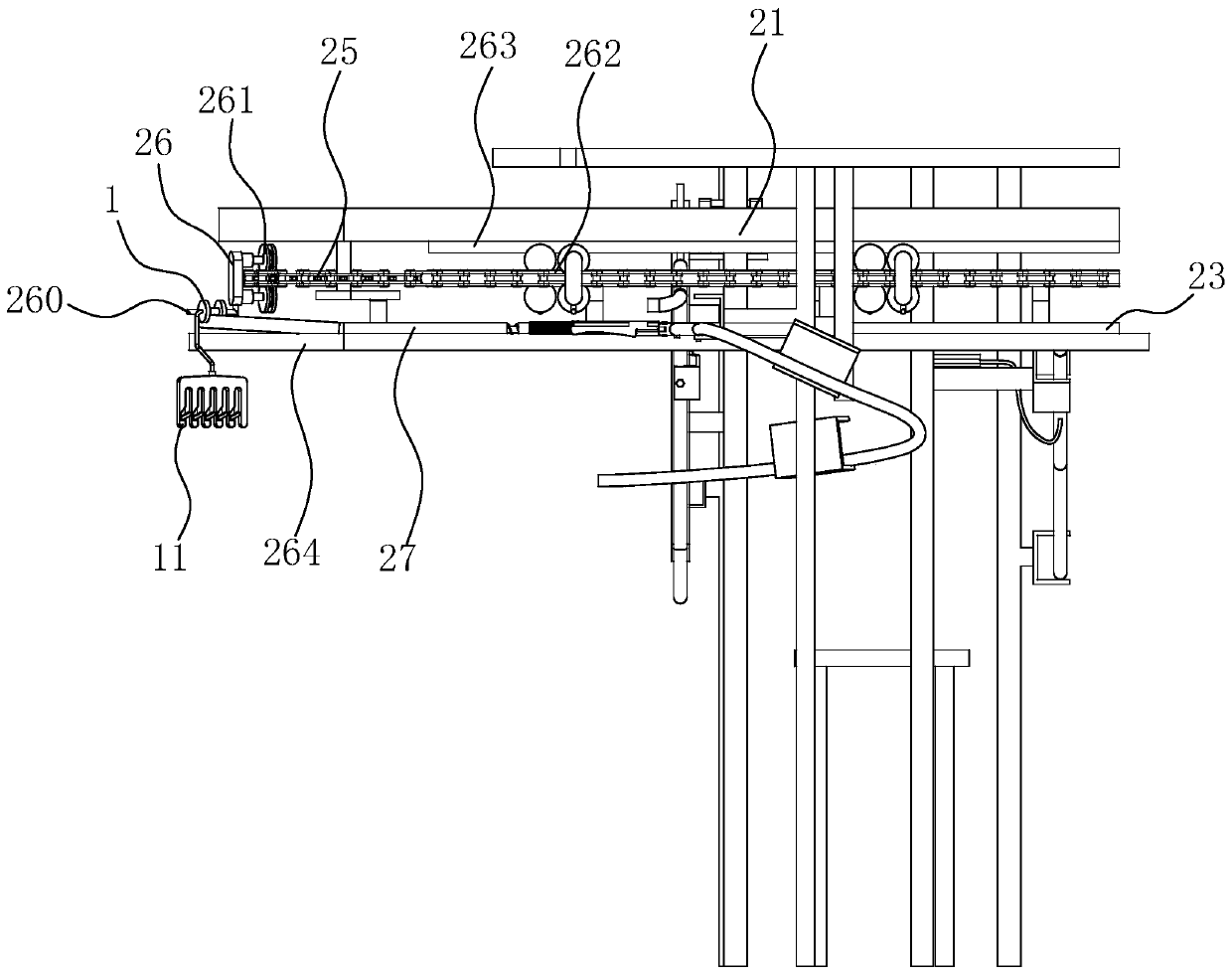

[0040] A garment hanging transmission system, such as figure 1 , image 3 As shown, the transmission assembly is suspended and fixed at the top position of the working environment, and the transmission assembly can be transported by the hanger wheel 1. In this embodiment, the transmission assembly includes a fixed frame 21, and the top position of the fixed frame 21 is suspended At the top position of the working environment, a plurality of "L"-shaped installation bars 22 are vertically arranged at the bottom position of the fixed frame 21, and at the same time, a plurality of sprockets are rotatably connected at the inner bottom position of the fixed frame 21 24. The sprockets 24 are installed uniformly and horizontally along the extension direction of the fixed frame 21 at the bottom position of the fixed frame 21, and an integrally closed transmission chain 25 is wound and connected at the wheel wall positions of these sprockets 24. The sprocket 24 is driven by a power par...

Embodiment 2

[0053] In this embodiment, the difference between this embodiment and Embodiment 1 lies in the difference of the station output components, such as figure 1 , Figure 7 As shown, the station output assembly includes a second inbound rail 32 , which is installed on the support 3 and just located at one side of the main transport rail 23 .

[0054] An abutment head 321 is arranged at the end position of the second inbound track 32 close to the main transmission rail 23, and at the same time, on the abutment head 321, a second auxiliary that can change the track of the clothes hanger wheel 1 to the second inbound track 32 is installed. Connecting piece, in this embodiment, the second auxiliary connecting piece includes a card slot 323 opened at the side wall of the main transmission rail 23 and consistent with the extension direction of the main transmission rail 23, and the abutting joint 321 is close to the card slot 323 A hook 324 is fixed at one end, and the hook 324 is matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com