Low-unwinding-force polyethylene low-viscosity protective film and preparation method thereof

A polyethylene and protective film technology, applied in the direction of mineral oil hydrocarbon copolymer adhesives, adhesives, adhesive types, etc., can solve problems such as residue or erosion, time-consuming, laborious and costly, and reduce unwinding force, etc., to facilitate the assembly line Operation processing and production, simple and easy operation, solve the effect of large unwinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below through specific embodiments.

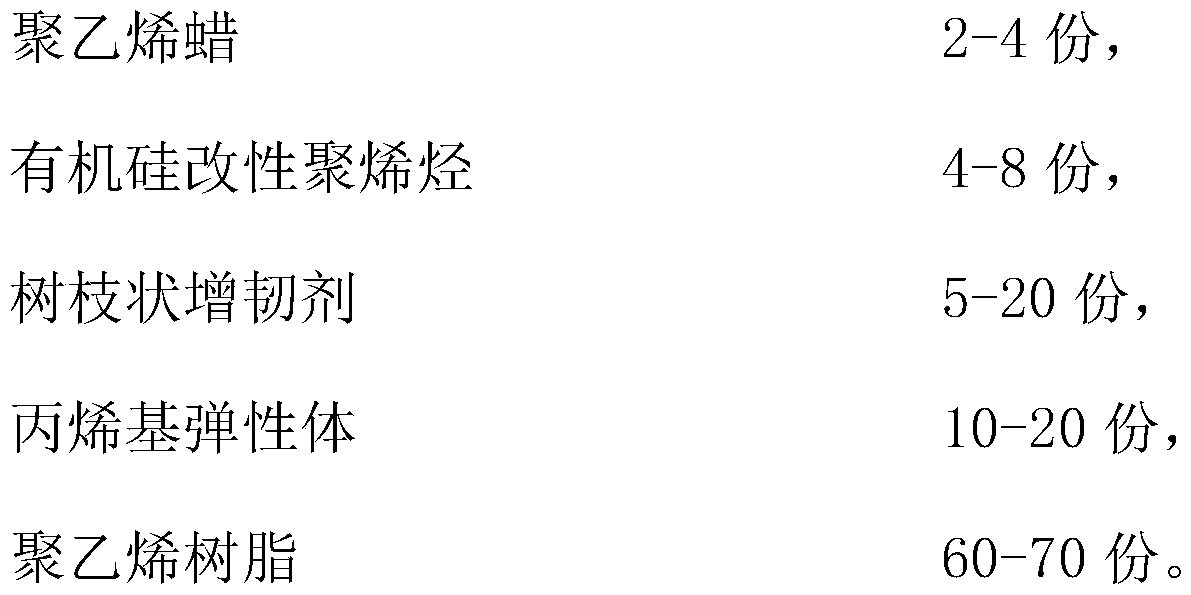

[0039] A polyethylene low-viscosity protective film with low unwinding force, the protective film is composed of three layers of surface layer, core layer and self-adhesive layer, the core layer is between the surface layer and the self-adhesive layer; the raw material of the surface layer includes polyethylene wax , Silicone modified polyolefin and dendritic toughener.

[0040] The polyethylene wax and silicone-modified polyolefin contained in the surface layer have good lubricity, scratch resistance, wear resistance, polishing resistance, engraving resistance, and anti-adhesion performance, which can prevent and overcome the surface layer and self-adhesion after rolling. Bonding and degumming between the layers play a role in reducing the unwinding force of the protective film.

[0041] The dendritic toughening agent is combined with the polymer chains of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com