A novel high-viscosity protective film and its preparation method

A protective film and high-viscosity technology, which is applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of easy adhesion between the surface layer and the adhesive layer, and is not easy to peel off, so that the adhesion force has little influence with temperature and time. Easy to peel, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

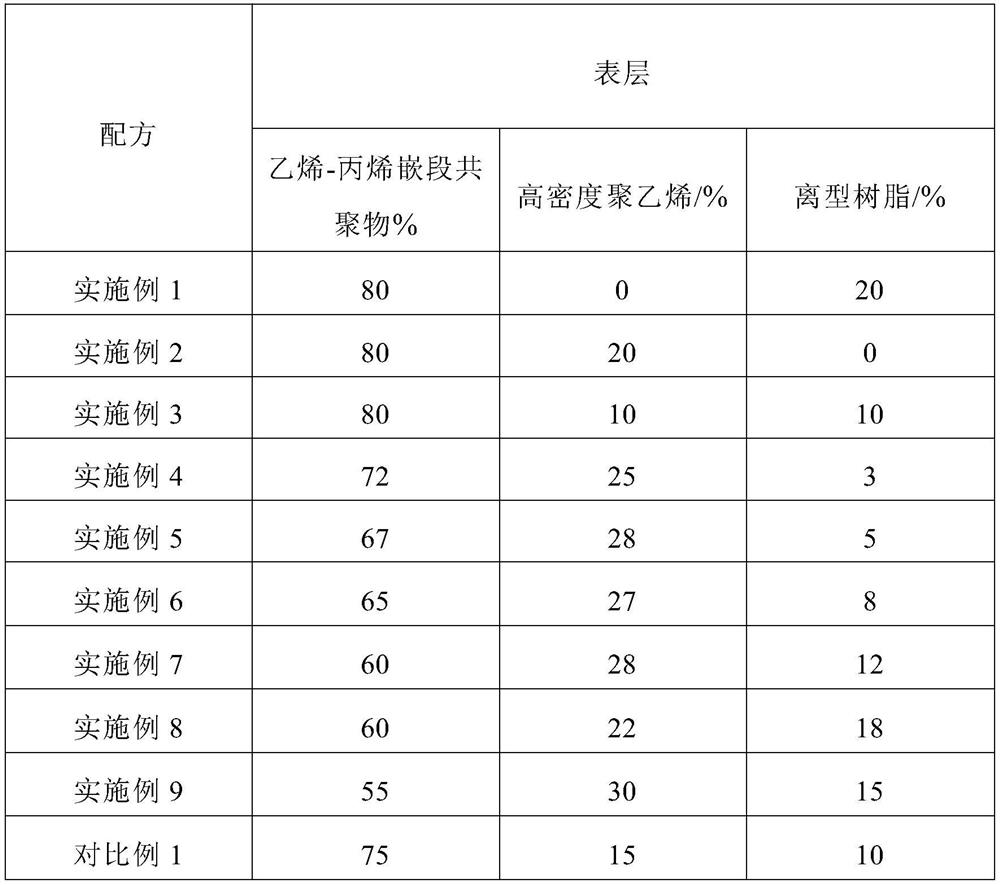

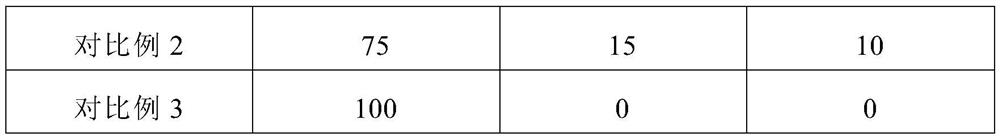

Embodiment 1

[0029] The novel high-viscosity protective film provided by the invention sequentially comprises a surface layer, a core layer and an adhesive layer.

[0030] The surface layer is made of ethylene-propylene block copolymer and release resin at a ratio of 80%:20%. The density of ethylene-propylene block copolymer is 0.90g / cm 3 , The melt index is 9.0g / 10min. The release resin is a vinyl polymer chemically modified by styrene (produced by Mitsubishi Chemical, the brand is W200P).

[0031] The core layer adopts ethylene-propylene block copolymer with a weight percentage of 100%, and its density is 0.90g / cm 3 , The melt index is 5.0g / 10min.

[0032] The adhesive layer adopts methyl methacrylate-butyl acrylate-methyl methacrylate block copolymer with a density of 1.13g / cm 3 , The melt index is 1.2g / 10min.

[0033] The surface layer had a thickness of 10 μm, the core layer had a thickness of 30 μm, and the adhesive layer had a thickness of 10 μm.

Embodiment 2

[0035] As the novel high-viscosity protective film that embodiment 1 provides, the difference is:

[0036] The surface layer is made of ethylene-propylene block copolymer and high-density polyethylene at a ratio of 80%:20%. The density of ethylene-propylene block copolymer is 0.90g / cm 3 , The melt index is 9.0g / 10min. The density of high-density polyethylene is 0.945g / cm 3 .

Embodiment 3

[0038] As the novel high-viscosity protective film that embodiment 1 provides, the difference is:

[0039] The surface layer is made of ethylene-propylene block copolymer, high-density polyethylene and release resin at a ratio of 80%:10%:10%. The density of ethylene-propylene block copolymer is 0.91g / cm 3 , The melt index is 4.0g / 10min. The density of high-density polyethylene is 0.963g / cm 3 . The release resin is a vinyl polymer chemically modified by styrene (produced by Mitsubishi Chemical, the brand is W200P).

[0040] The adhesive layer adopts methyl methacrylate-butyl acrylate-methyl methacrylate block copolymer. Its density is 1.11g / cm 3 , The melt index is 1.5g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com