Fully-fabricated stair system and fabrication method

A fully assembled, staircase technology, applied in the direction of stairs, ladder-like structures, treads and riser units, etc., can solve the problem of weakening the safety performance and seismic performance of stairs, not fully considering the integrity of stairs, and affecting the efficiency of stair component production, etc. problems, to achieve the effect of reducing the maintenance site, improving the utilization rate, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

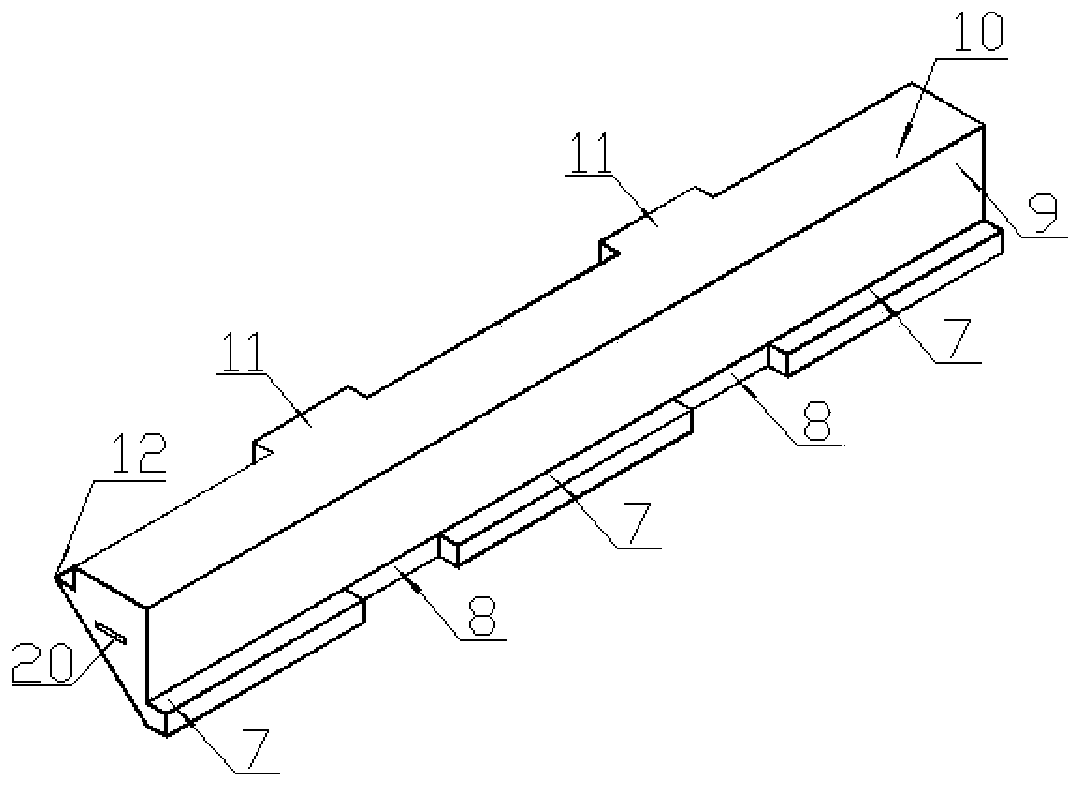

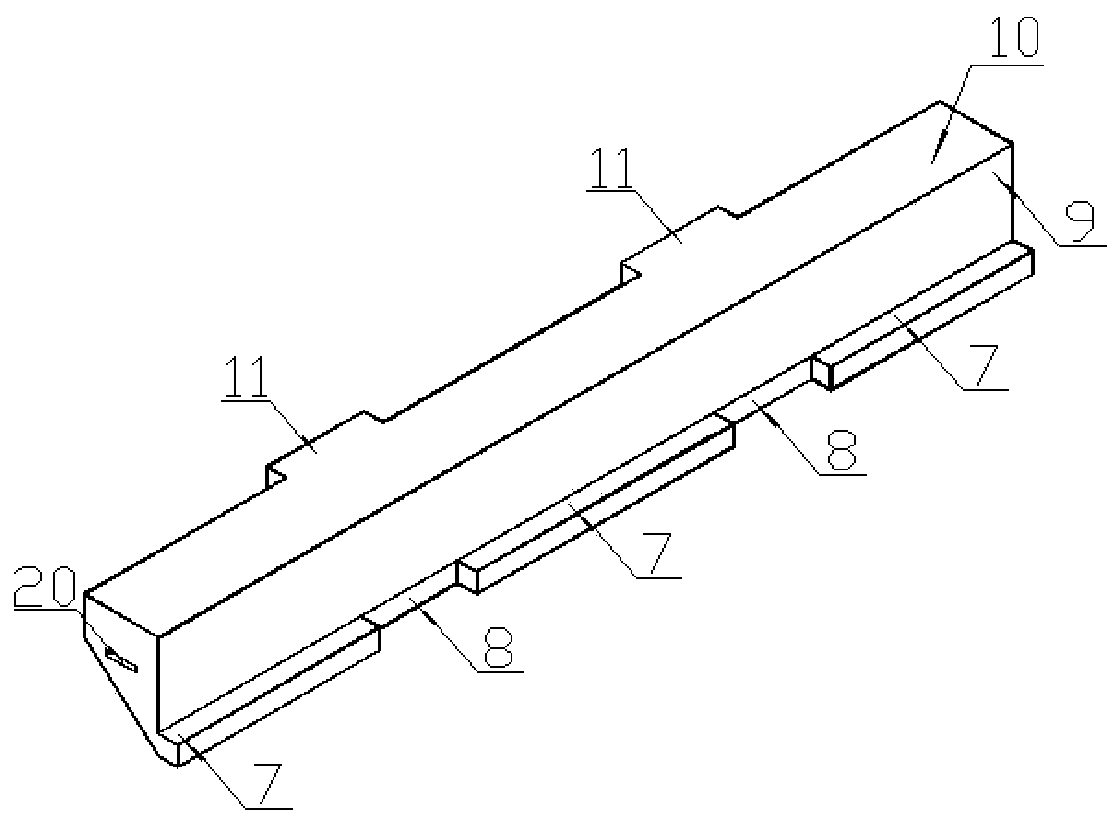

[0035] The fully assembled staircase system of the present invention includes: prefabricated components such as stair plate LTB, step unit, stair beam TL, platform plate PB, handrail GLB, handrail steel column GLZ, etc. A series of construction measures and methods of specific settings carry out on-site assembly of the various components of the staircase. in:

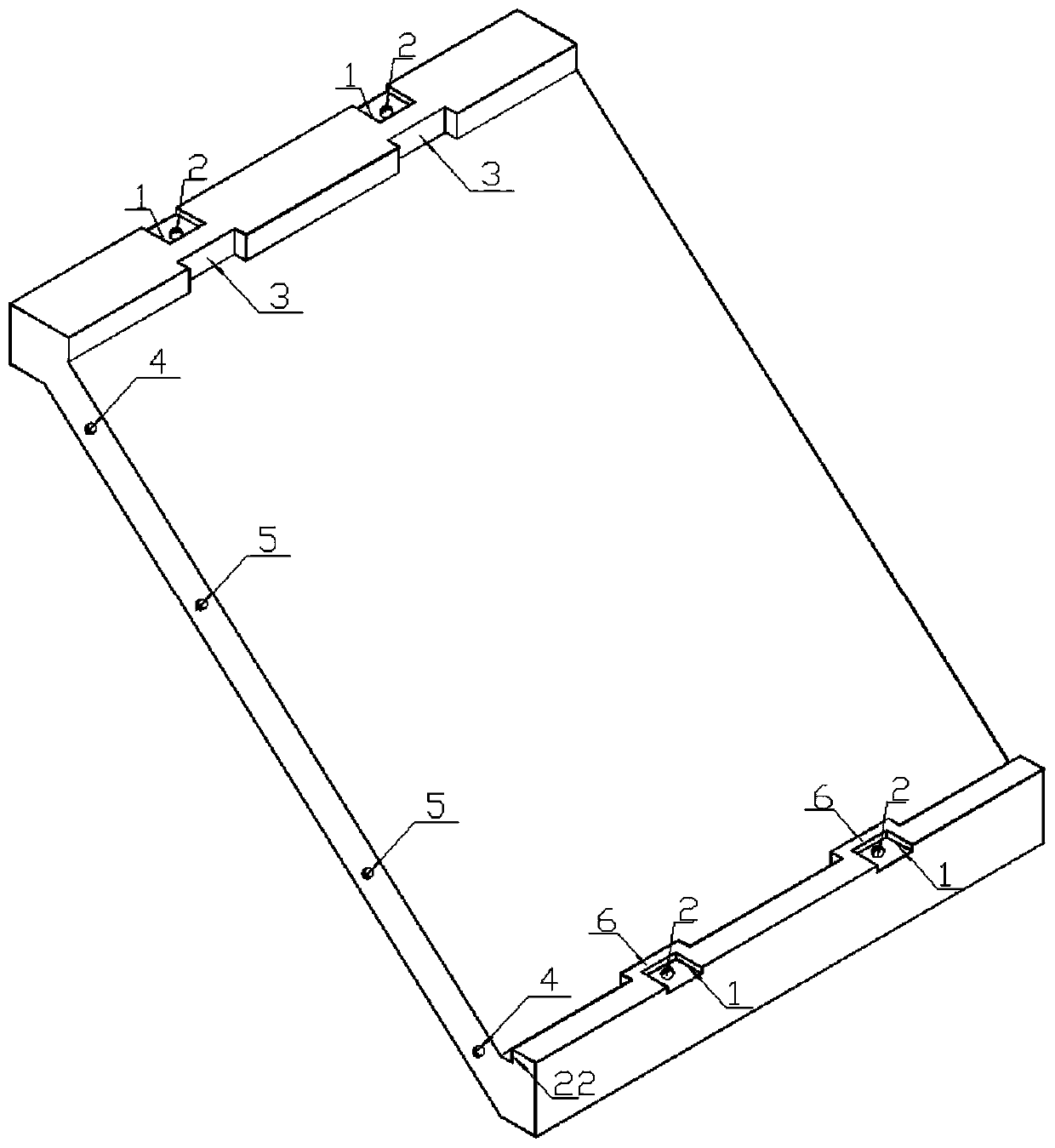

[0036] Stairs LTB (such as figure 1As shown), it is a smooth reinforced concrete slab prefabricated by steel mold in the prefabricated component factory. The upper and lower ends of the slab are provided with joints connected with the stair beams, and each lap joint is provided with two first grooves 1, which are used to place and fix the steel connector GLJ, and connect the stair beam TL and the platform through the steel connector GLJ. The boards PB are connected as a whole to improve the integrit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com