Pipe curtain cover excavation reverse construction method for subway station construction

A technology of reverse operation of subway stations and cover-excavation, applied in the field of engineering, can solve problems such as traffic congestion, large work space, and low construction efficiency, and achieve the effect of effectively avoiding and avoiding inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

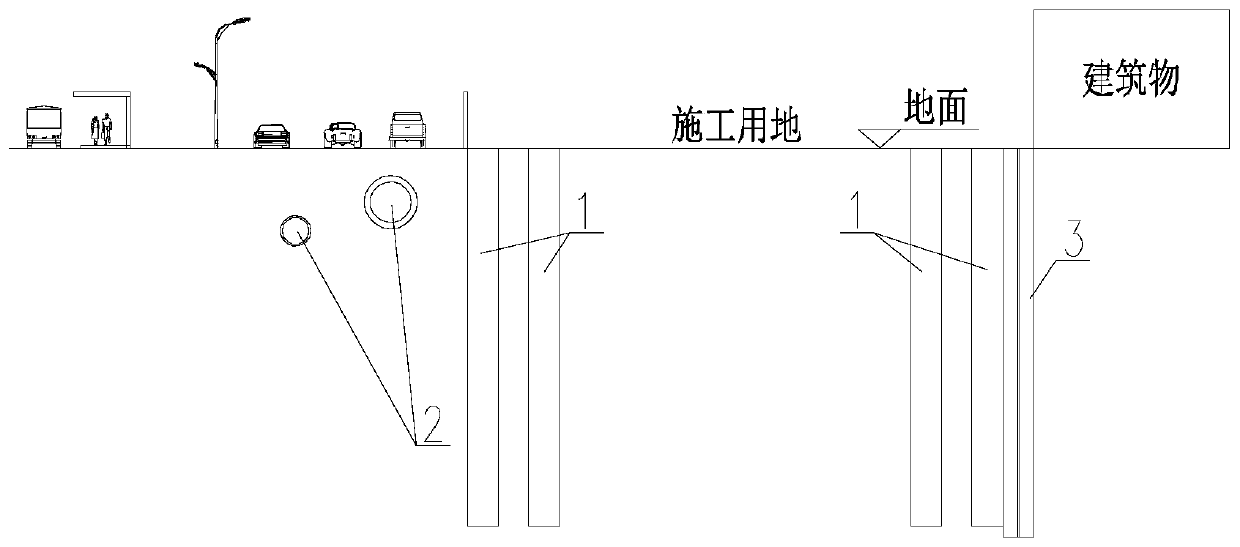

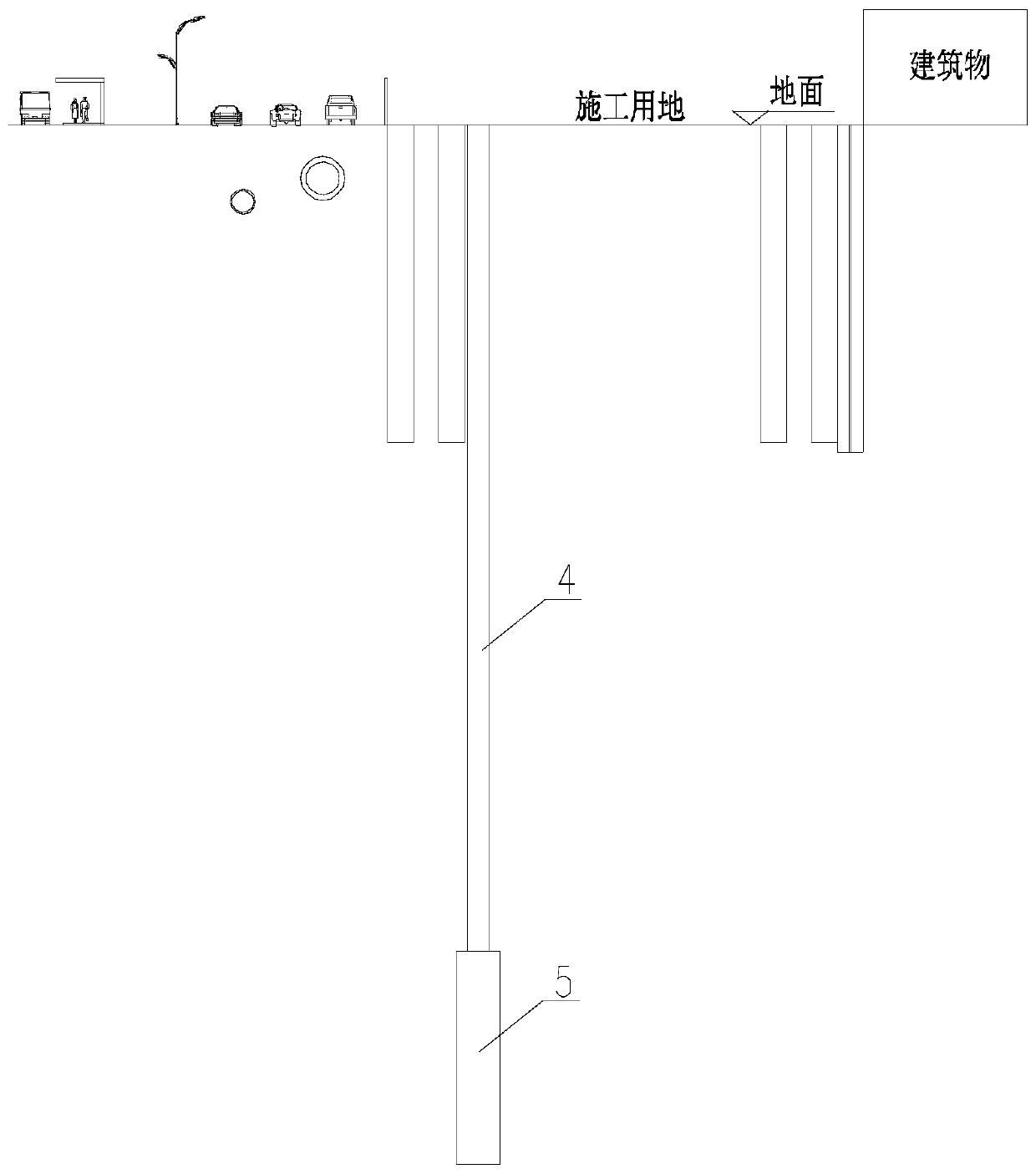

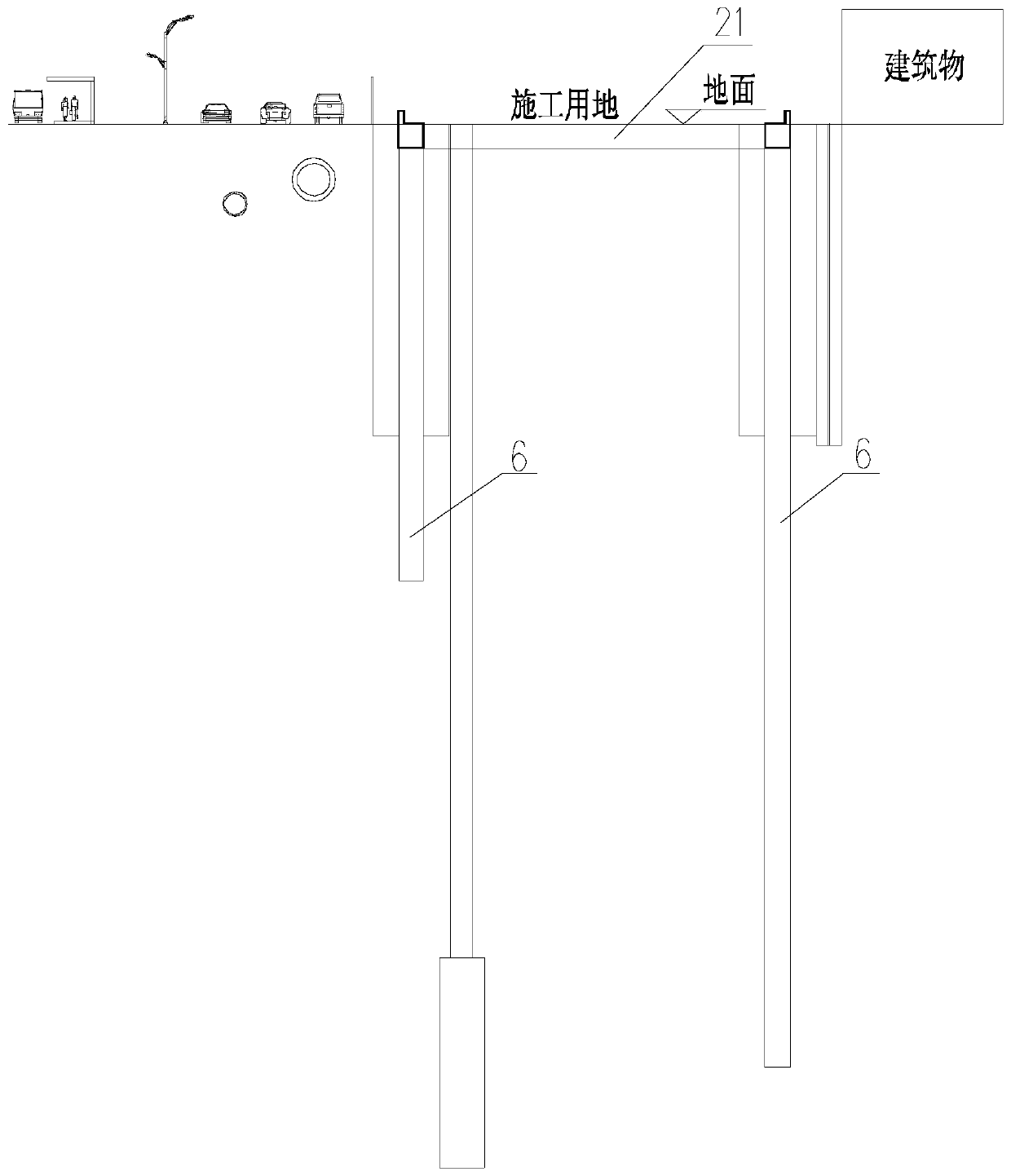

[0050] as attached Figure 1-9 As shown, the present embodiment provides a construction method for pipe curtain cover excavation and reverse work for subway station construction, which specifically includes the following steps:

[0051] Step 1. Carry out traffic enclosure on the ground of the right line of the subway station; avoid the existing underground pipeline 2, carry out the construction of the groove wall reinforcement mixing pile 1 on both sides of the right line of the station, and construct the building isolation pile 3 on the right side of the right line of the station Construction, building isolation pile 3 adopts double-pipe rotary grouting pile;

[0052] Step 2. Construct the steel pipe column 4 and the pile foundation 5 on the right side of the reinforced mixing pile on the left side of the channel wall on the right line of the station. The pile foundation 5 is arranged at the lower end of the steel pipe column 4, and the column center of the steel pipe column ...

Embodiment 2

[0060] Embodiment 2 has basically the same principles and ideas as Embodiment 1, except that when the existing underground pipeline 2 is located on the right line of the station or the left line of the station is constructed first, the construction direction is opposite to that in Embodiment 1, and the construction procedure is Similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com