Built-in vertical oil separator for compressor

An oil separator and compressor technology, applied in the field of compressor oil separation, can solve problems such as increased energy consumption, affecting system efficiency, compressor shaft locking, etc., to reduce oil carrying rate, reduce volume, and improve oil separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

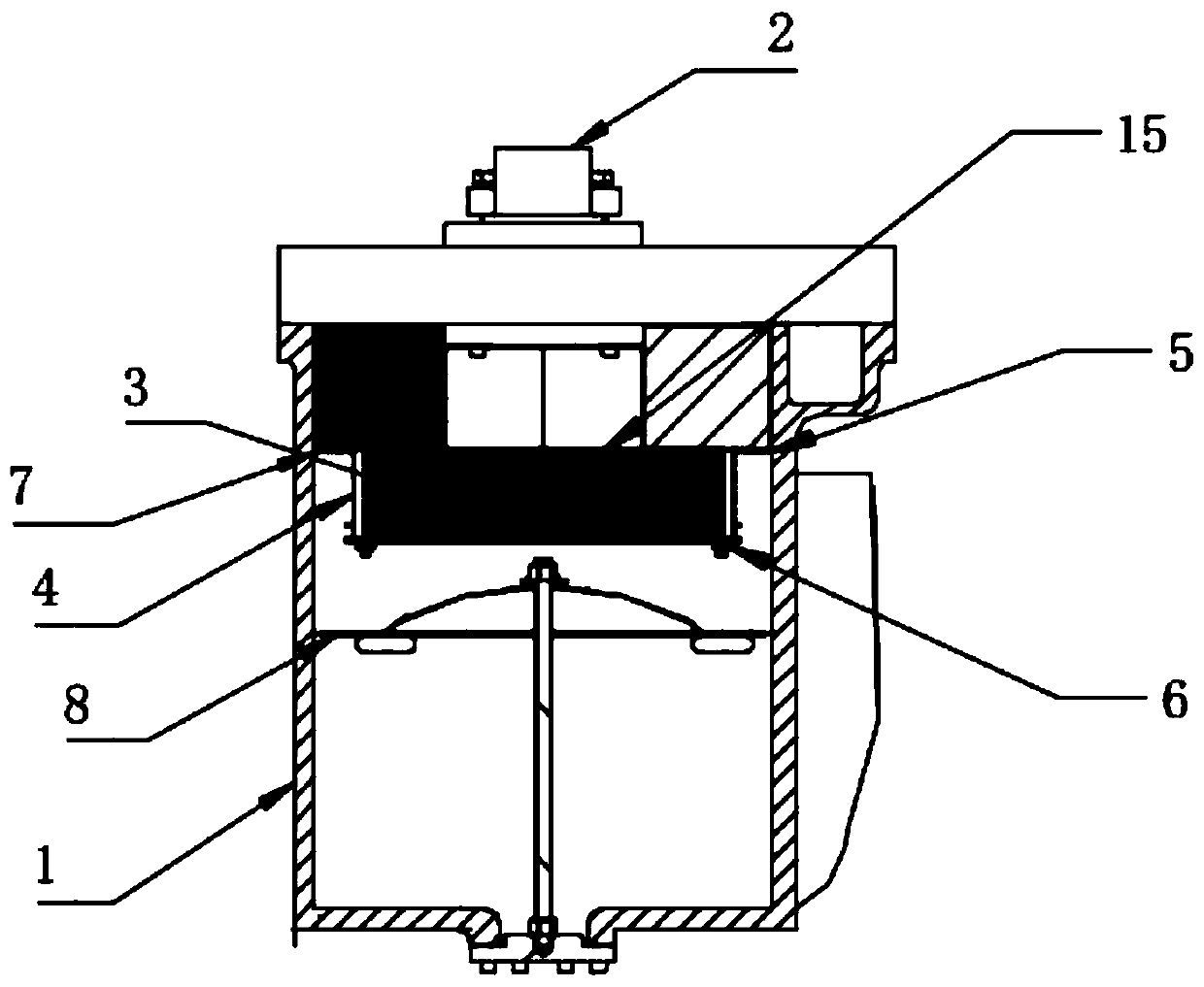

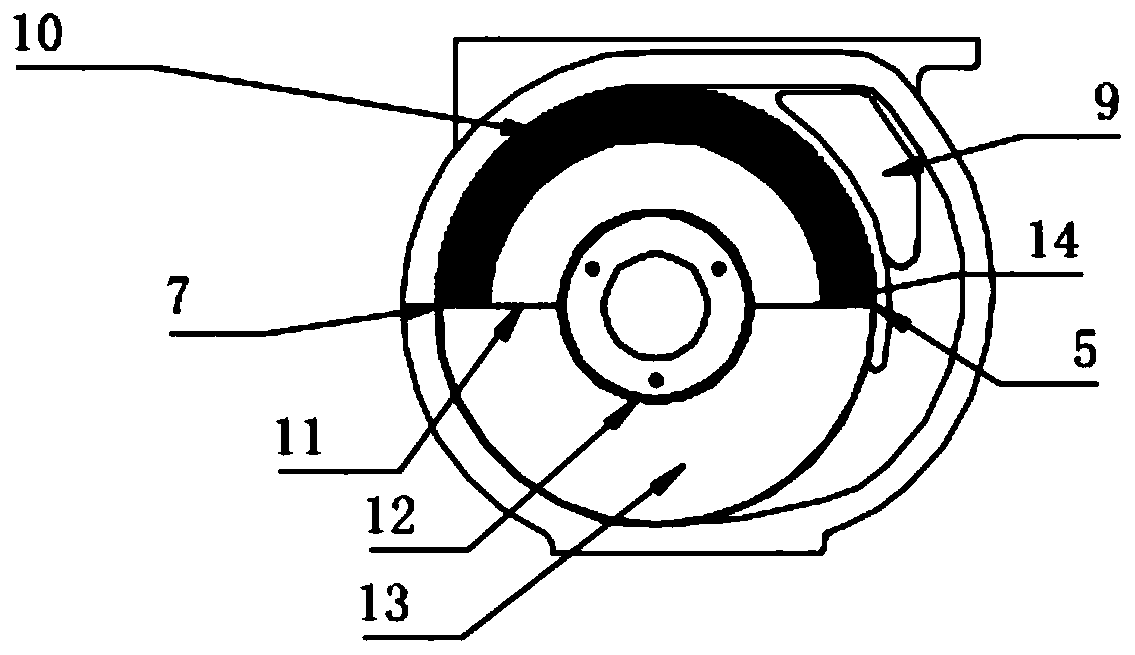

[0034] Please refer to Figure 1 to Figure 2 , Embodiment 1 of the present invention is:

[0035] A built-in vertical oil separator for compressors, one end of the oil separator is in contact with the bearing box of the compressor, the compressor exhausts from the exhaust port of the bearing box, and the gas enters the oil separator from the initial exhaust port 9 The oil separator includes a barrel body 1, the upper part of the barrel body 1 is provided with an initial exhaust port 9 and a guide channel, one end of the initial exhaust port 9 is connected to the guide channel, and the initial exhaust port 9 is connected to the guide channel. The other end of the port 9 is connected to the exhaust port of the compressor, and the guide channel is connected with the first metal filter screen 10 through a porous mesh plate 11, and the guide channel and the first metal filter screen 10 are arranged at the same level In terms of height, a second metal filter screen 15 is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com