Device and method for testing adhesive property of fiber reinforced composite reinforced concrete

A composite material and fiber-reinforced technology, which is applied in the field of fiber-reinforced composite material-reinforced concrete bonding performance test device, can solve the problems of unable to test the interface between FRP and concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

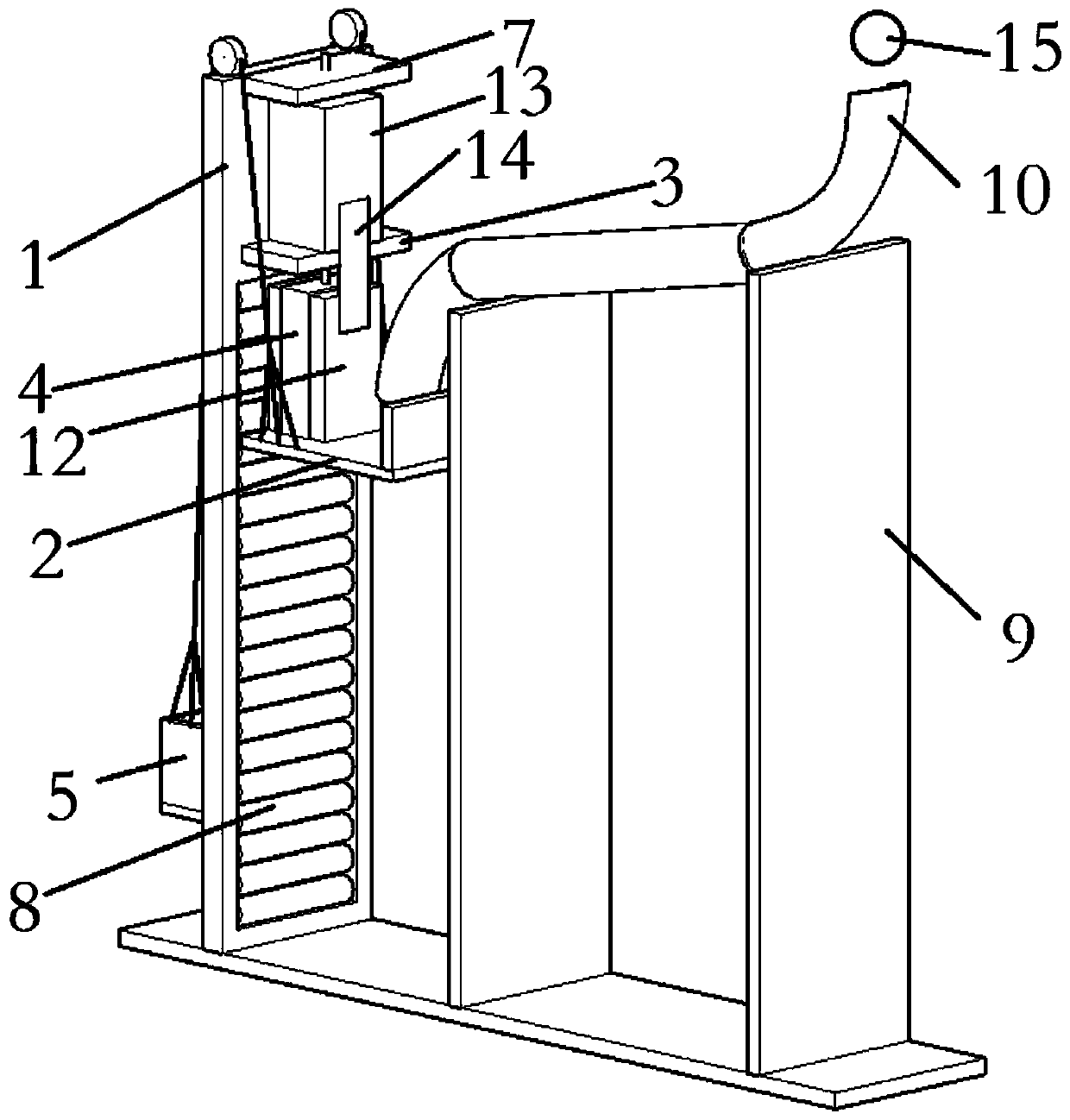

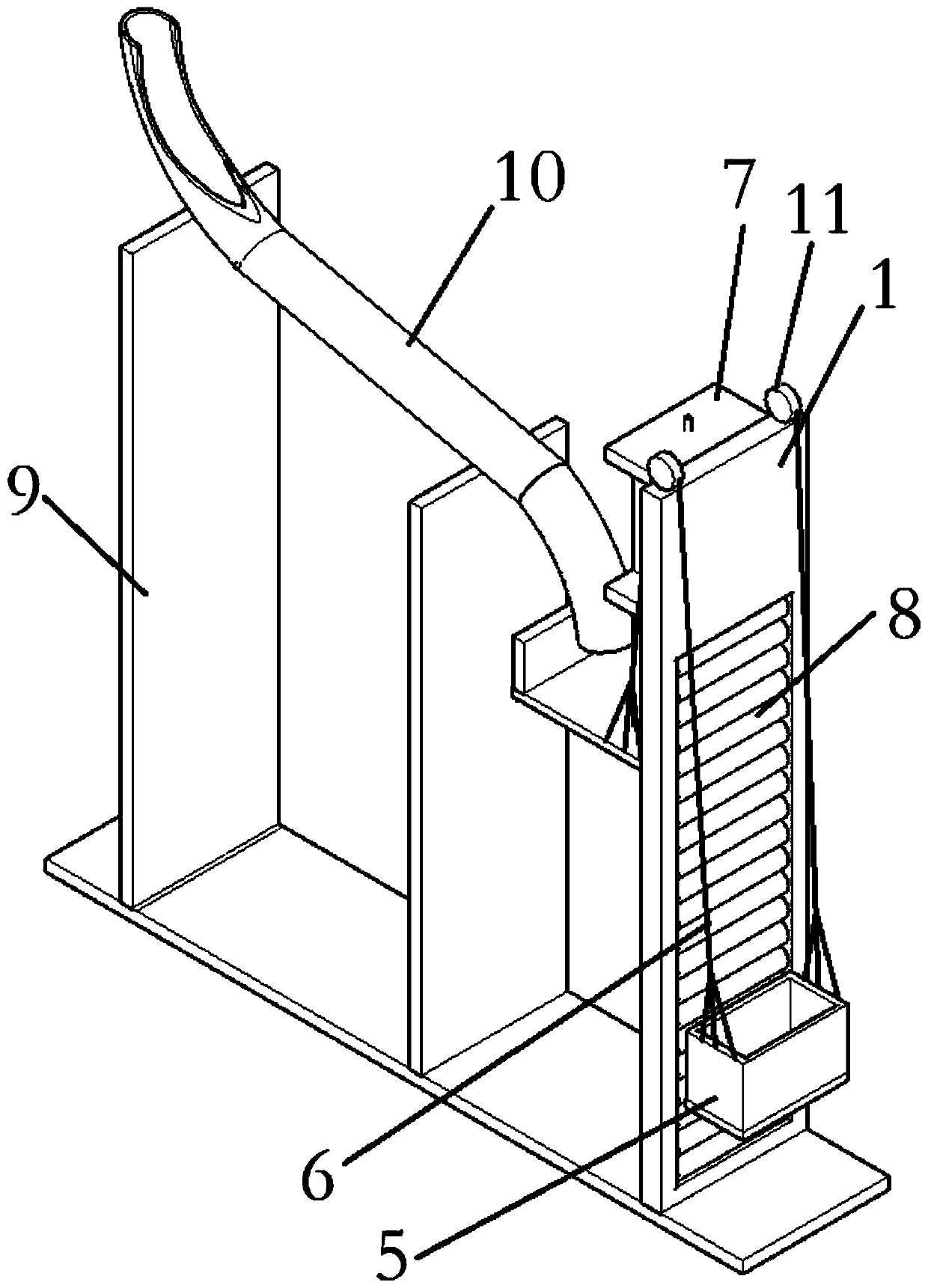

[0035] Such as figure 1 and figure 2Shown is a specific embodiment of the fiber-reinforced composite material-reinforced concrete bonding performance test device provided by the present invention, including a mounting bracket 1 and two auxiliary plates 9 installed in parallel on the connecting plate in turn, and the two auxiliary plates 9 A force-applying track 10 is installed on the top to limit the movement path of the impact member 15 .

[0036] The movable platform 2, the fixed platform 3 and the baffle plate 7 are successively installed on the mounting bracket 1 from bottom to top, the movable platform 2, the fixed platform 3 and the baffle plate 7 are horizontally arranged and parallel to each other, and the movable platform 2 extends outwards with an impact portion, and the The force track 10 is a bent track with a height difference in the vertical direction, and the side wall of the inlet end is provided with an opening, and the opening is provided with a scale, and ...

Embodiment 2

[0040] A method for testing the bond performance of fiber reinforced composite reinforced concrete, comprising the following steps:

[0041] The first test piece 12 and the second test piece 13 are connected through the fiber reinforced composite material sheet 14, the first test piece 12 is loaded in the first storage space, the second test piece 13 is loaded in the second storage space, and balance Balance weights are loaded into the box 5, so that the movable platform 2 and the first test block 12 maintain a balanced state with the balance box 5 and the balance weights. The first test block 12 is clamped on the fixed platform 3 by adjusting the first clamping screw and the second test block 13 is clamped on the movable platform 2 by adjusting the second clamping screw.

[0042] The impact part 15 falls from the force application track 10 and hits the impact part of the movable platform 2, so that the interface between the fiber reinforced composite material sheet 14 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com