Fuel cell system with waterway pressure regulating function

A fuel cell system and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of membrane electrode flooding, reduced battery performance and reliability, damage, etc., and achieve the effect of simple and easy system process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

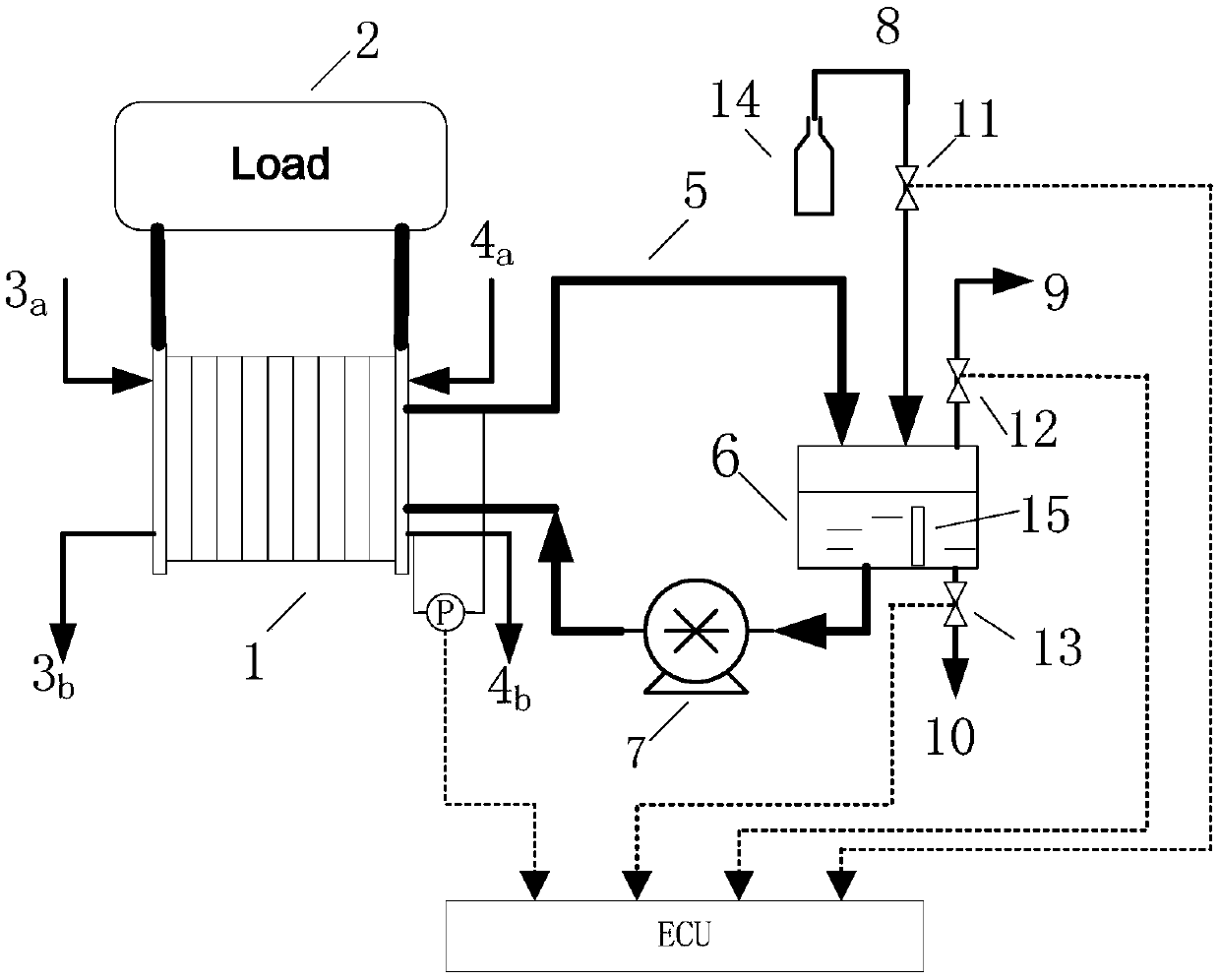

Embodiment 1

[0034] Such as figure 1 As shown, a fuel cell system with water pressure regulation function includes a water tank 6, a high-pressure gas source 14, a gas injection pipeline 8, an exhaust pipeline 9 and a drainage pipeline 10; the water tank 6 is arranged in the cooling water circuit of the fuel cell Among them, a float level gauge 15 is installed in the water tank 6, and the liquid level gauge 15 is connected to the ECU of the fuel cell control system. The exhaust pipeline 9 and the drainage pipeline 10 are relatively independent. The gas injection pipeline 8 is connected to the high-pressure gas source 14 through the gas injection control valve 11. In this embodiment, the high-pressure gas source 14 uses an external high-pressure gas source. The gas control valve 11 is connected to an external high-pressure nitrogen cylinder; the exhaust pipeline 9 is connected to the top of the water tank, and the exhaust pipeline 9 is provided with an exhaust control valve 12, and the drai...

Embodiment 2

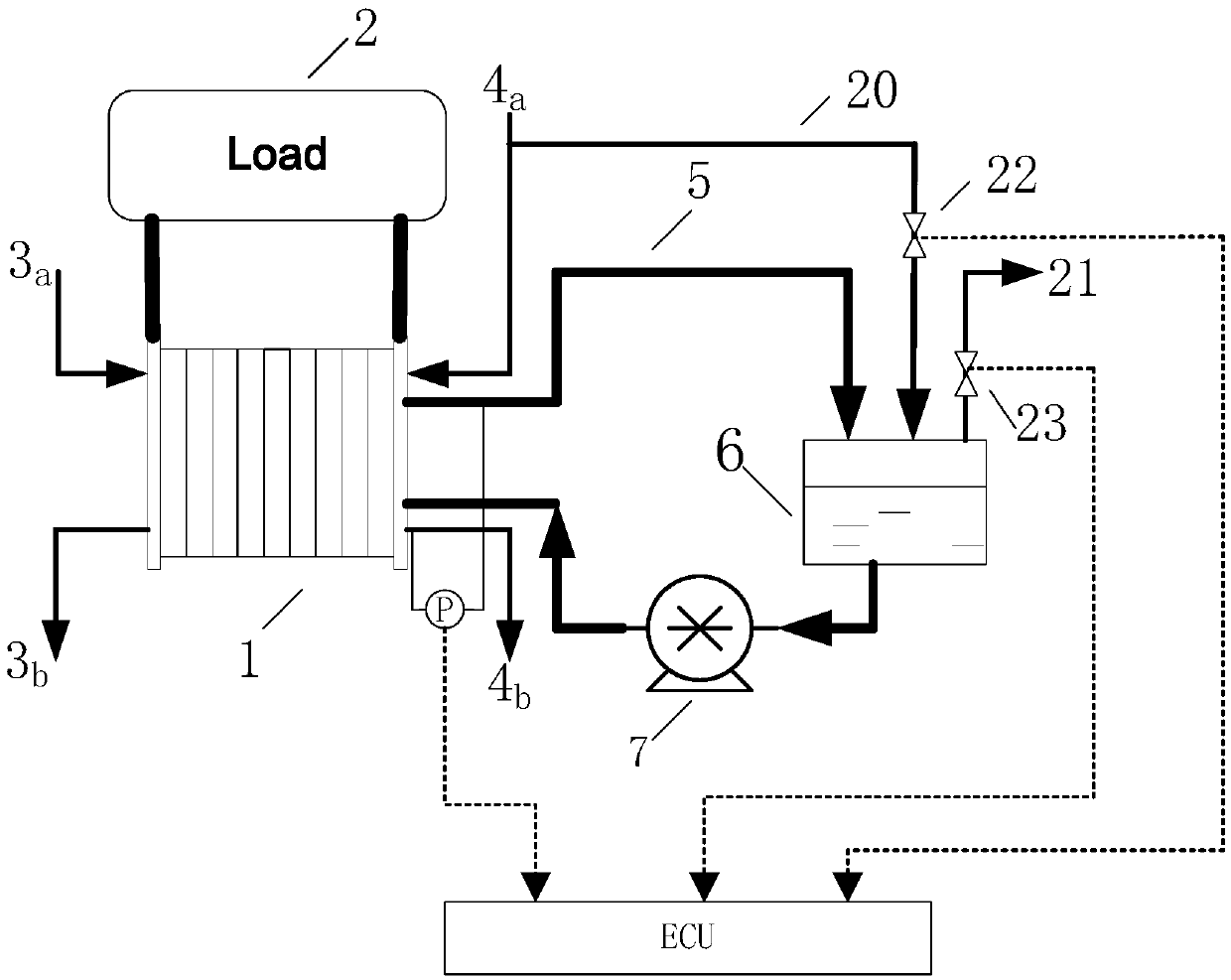

[0038] Such as figure 2 As shown, in this embodiment, a fuel cell system with waterway pressure regulation function, the gas injection pipeline 20 is directly connected to the oxidant inlet 4a through the gas injection control valve 22, that is, the oxidant inlet gas with higher pressure is used as the water tank 6 to inject gas The high-pressure gas source; Exhaust pipeline, drainage pipeline are merged into exhaust / water pipeline 21, connect exhaust / water control valve 23, other structures are identical with embodiment 1.

[0039] When the permeable bipolar plate fuel cell stack 1 is running, the ECU of the fuel cell control system monitors in real time the pressure difference P of the permeable plate of the permeable bipolar plate fuel cell stack 1 through the pressure sensor connected to the oxidant and the waterway. This embodiment The normal range of P is 0.2-0.4bar. When the ECU detects that the P value is higher than 0.4bar, and the cooling water channel needs to be ...

Embodiment 3

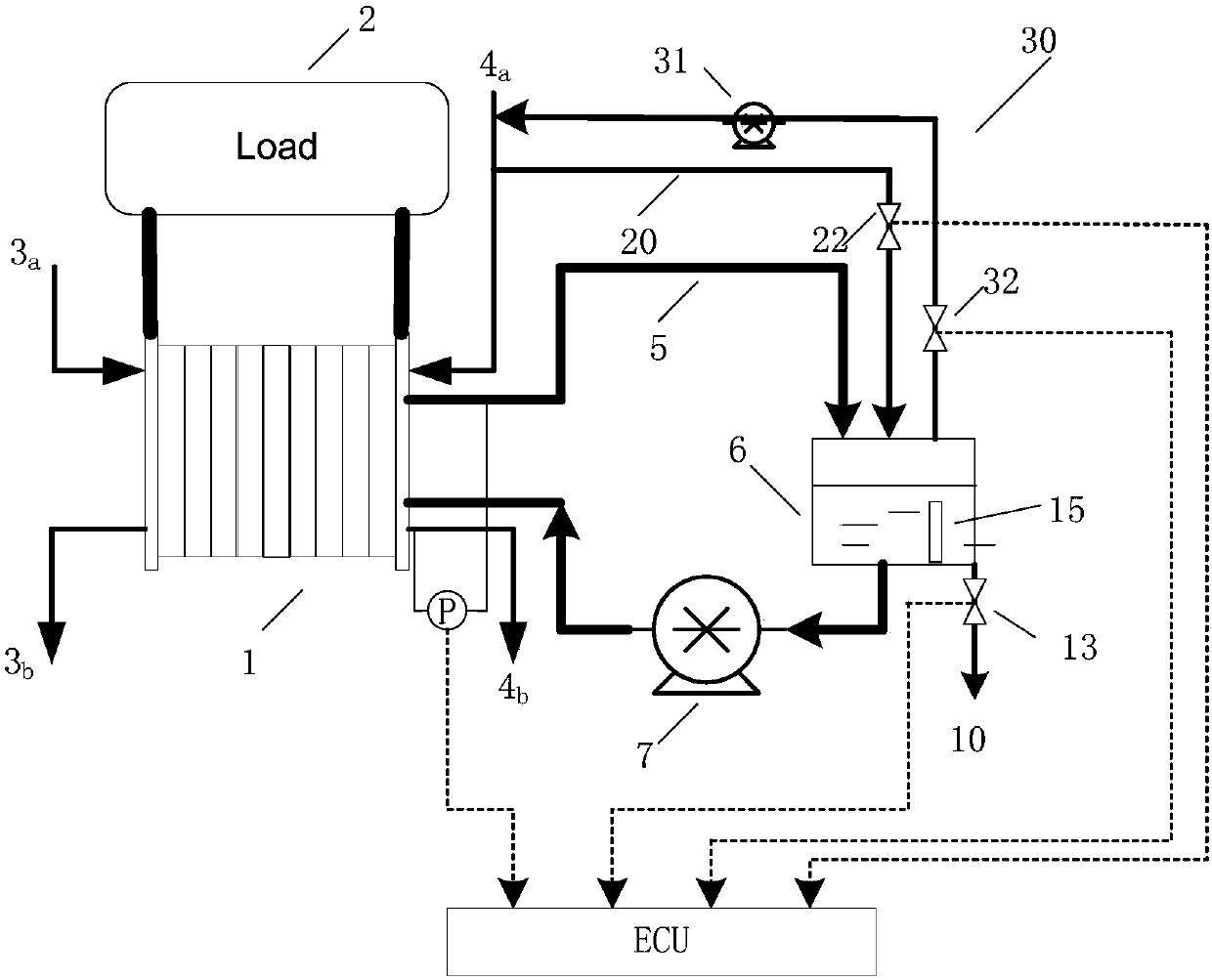

[0042] Such as image 3 As shown, in this embodiment, a fuel cell system with waterway pressure regulation function, the gas injection pipeline 20 is directly connected to the oxidant inlet 4a through the gas injection control valve 22, that is, the oxidant inlet gas with higher pressure is used as the water tank 6 to inject gas The high-pressure gas source; the exhaust pipeline 30 is directly connected to the intake pipeline of the oxidant inlet 4a through the exhaust control valve 32 and the air pump 31, and the exhaust control valve 32 and the air pump 31 are linked, and other structures are the same as in Embodiment 1.

[0043] Different from Embodiment 1 and Embodiment 2, the exhaust pipeline 30 does not directly discharge the excess gas in the water tank 6, but guides the gas back to the oxidant inlet 4a. Since the gas pressure at the oxidant inlet 4a is higher than the pressure of the water tank 6, an air pump 31 is provided in the exhaust pipeline 30 to increase the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com