Production process of vegetable protein artificial meat

A production process and plant protein technology, applied in the field of plant protein artificial meat production technology, can solve problems such as cost increase, and achieve the effects of low price, lower cost, and increased elasticity and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

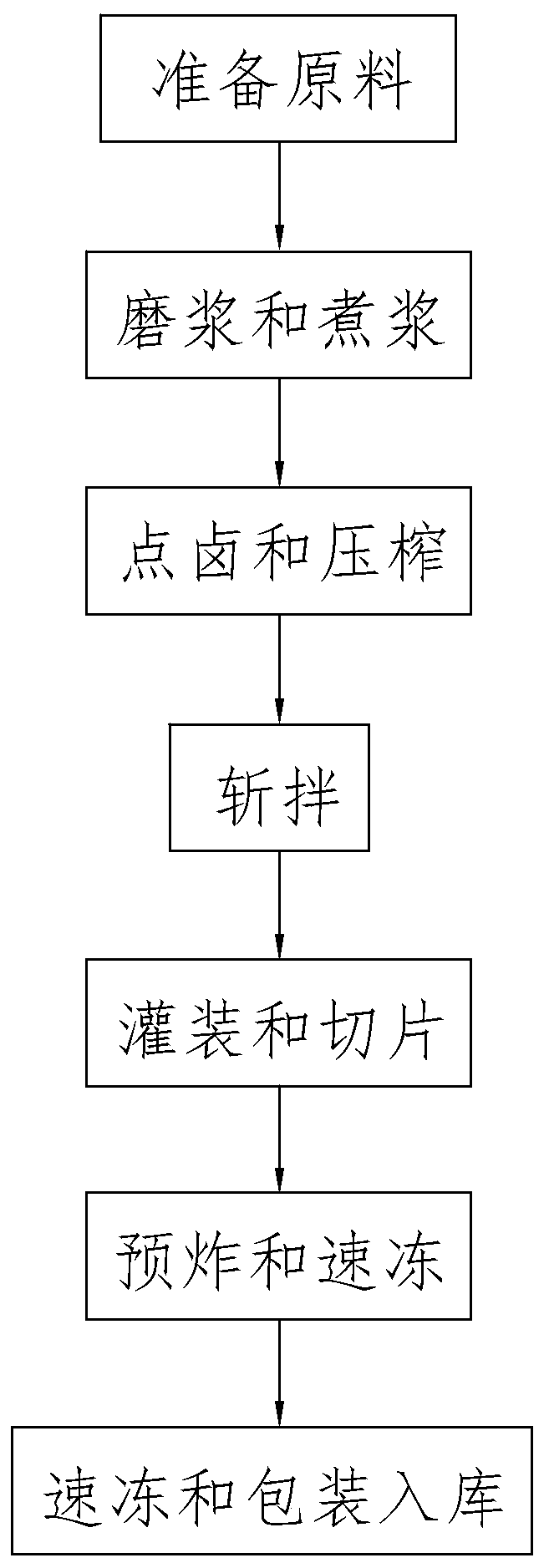

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: A kind of production technology of vegetable protein artificial meat, comprises following processing steps:

[0052] S1, preparing raw materials, washing soybean raw materials to remove impurities, and soaking soybean raw materials for 8 hours.

[0053] S2, refining and boiling, mixing the soaked soybean raw materials with water at a ratio of 60:39.35, grinding them into soybean milk, and boiling the soybean milk for 3 minutes at a temperature of 100°C.

[0054] S3, marinating and pressing, adding magnesium chloride to the boiled soybean milk to form soybean brains, the weight ratio of soybean raw materials, water and magnesium chloride is 60:39.35:0.65, putting the soybean brains into a press and pressing for 50 minutes to form dried soybeans.

[0055] S4, chopping and mixing, using a chopping machine to chop and mix the dried tofu obtained in step S3, then adding seasoning and chopping evenly to obtain fillings, the weight ratio of dried tofu and seasoni...

Embodiment 2-6

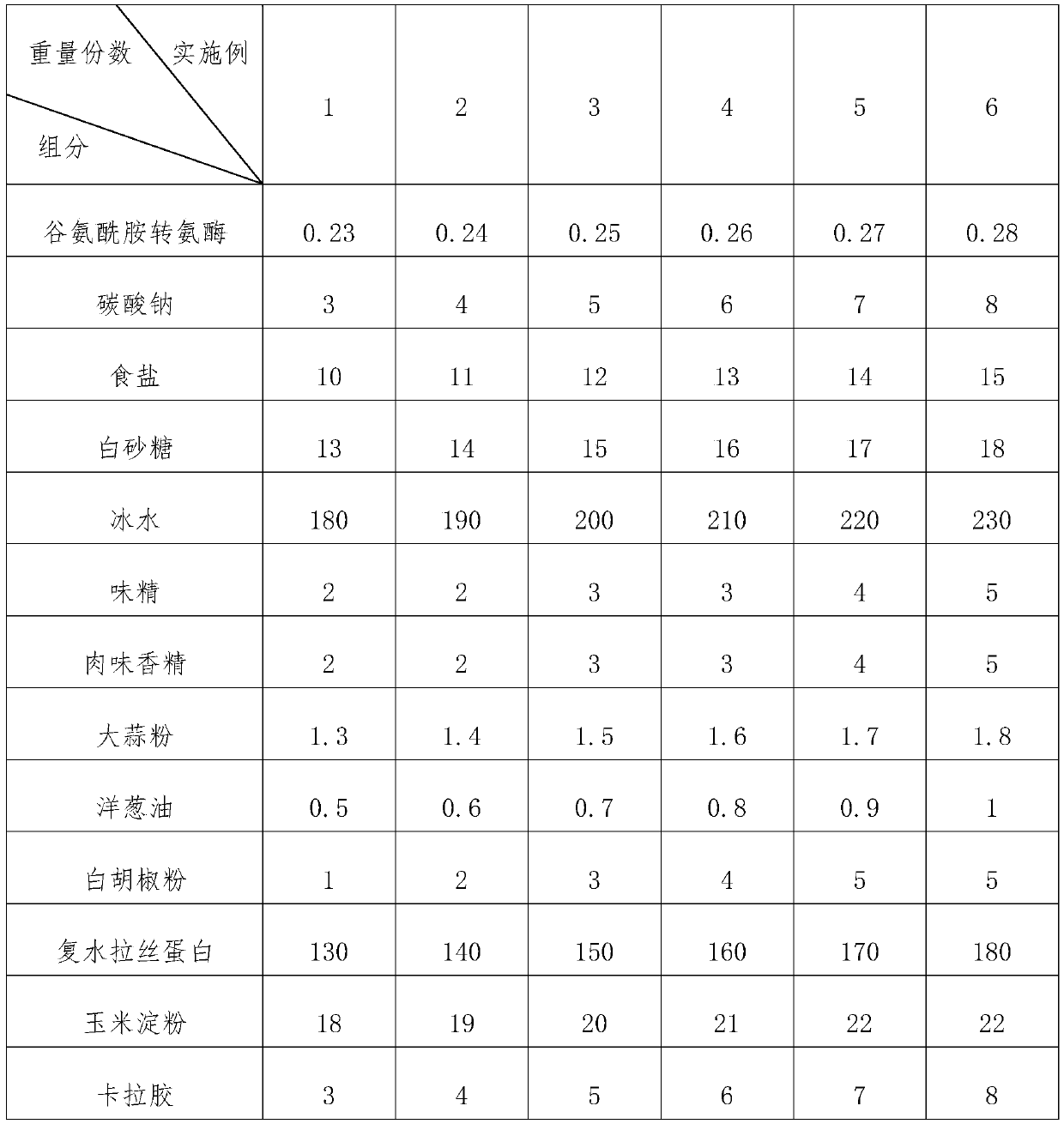

[0060] Example 2-6: A production process of vegetable protein artificial meat, the difference from Example 1 is that the components in the seasoning and their corresponding parts by weight are shown in Table 1.

[0061] Each component and parts by weight thereof in table 1 embodiment 1-6

[0062]

Embodiment 7

[0063] Example 7: A production process of vegetable protein artificial meat, which differs from Example 1 in that it includes the following steps: S1, preparing raw materials, washing soybean raw materials to remove impurities, and soaking soybean raw materials for 10 hours.

[0064] S2, refining and boiling, mixing the soaked soybean raw materials with water at a ratio of 60:39.35, grinding them into soybean milk, and boiling the soybean milk for 3 minutes at a temperature of 100°C.

[0065] S3, marinating and pressing, adding magnesium chloride to the boiled soybean milk to form soybean brains, the weight ratio of soybean raw materials, water and magnesium chloride is 60:39.35:0.65, putting the soybean brains into a press and pressing for 70 minutes to form dried soybeans.

[0066] S4, chopping and mixing, using a chopping machine to chop and mix the dried tofu obtained in step S3, then adding seasoning and chopping evenly to obtain fillings, the weight ratio of dried tofu an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com