Seaweed cubilose as well as preparation method and application thereof

A technology of bird's nest and seaweed, which is applied in the application, food ingredients as curing agent, function of food ingredients, etc., can solve the problems that natural bird's nest is difficult to meet the consumption needs of the people, cannot become popular food, and is expensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

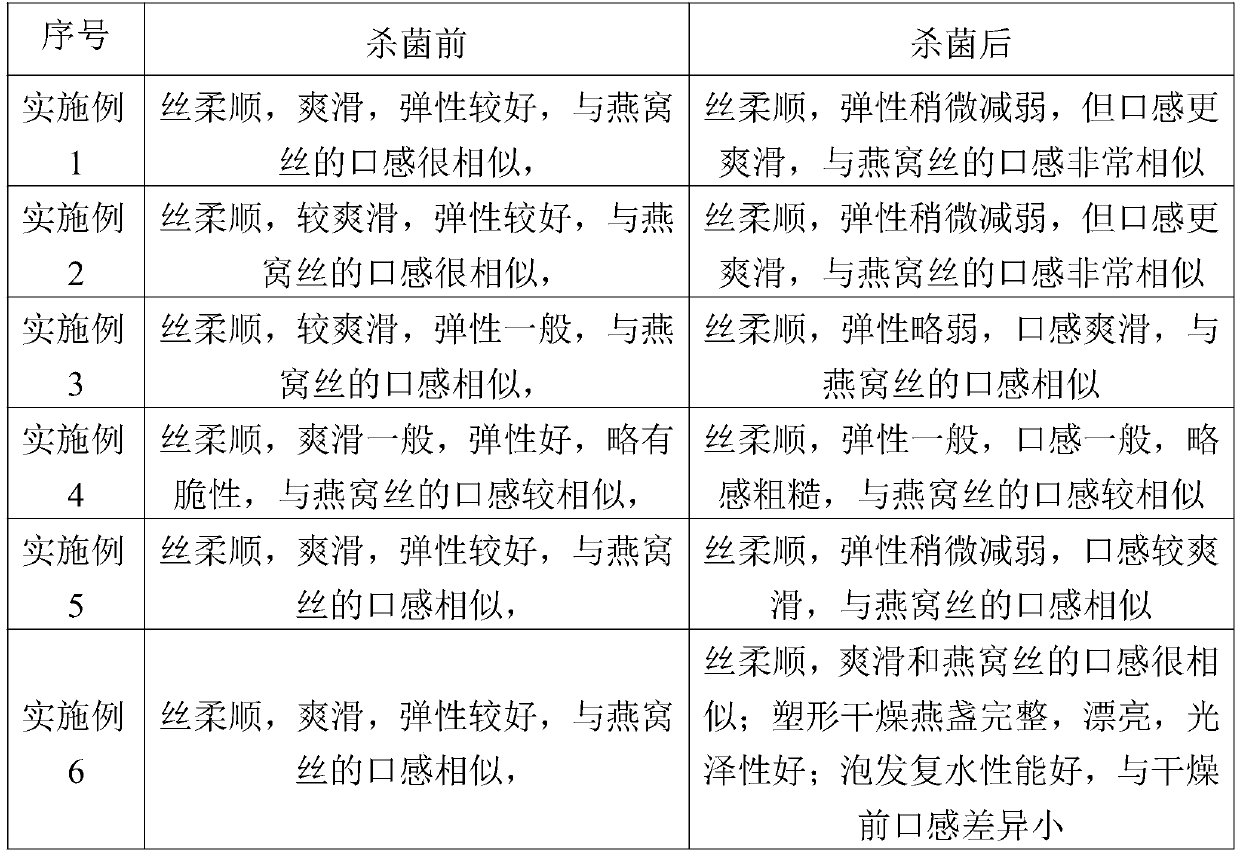

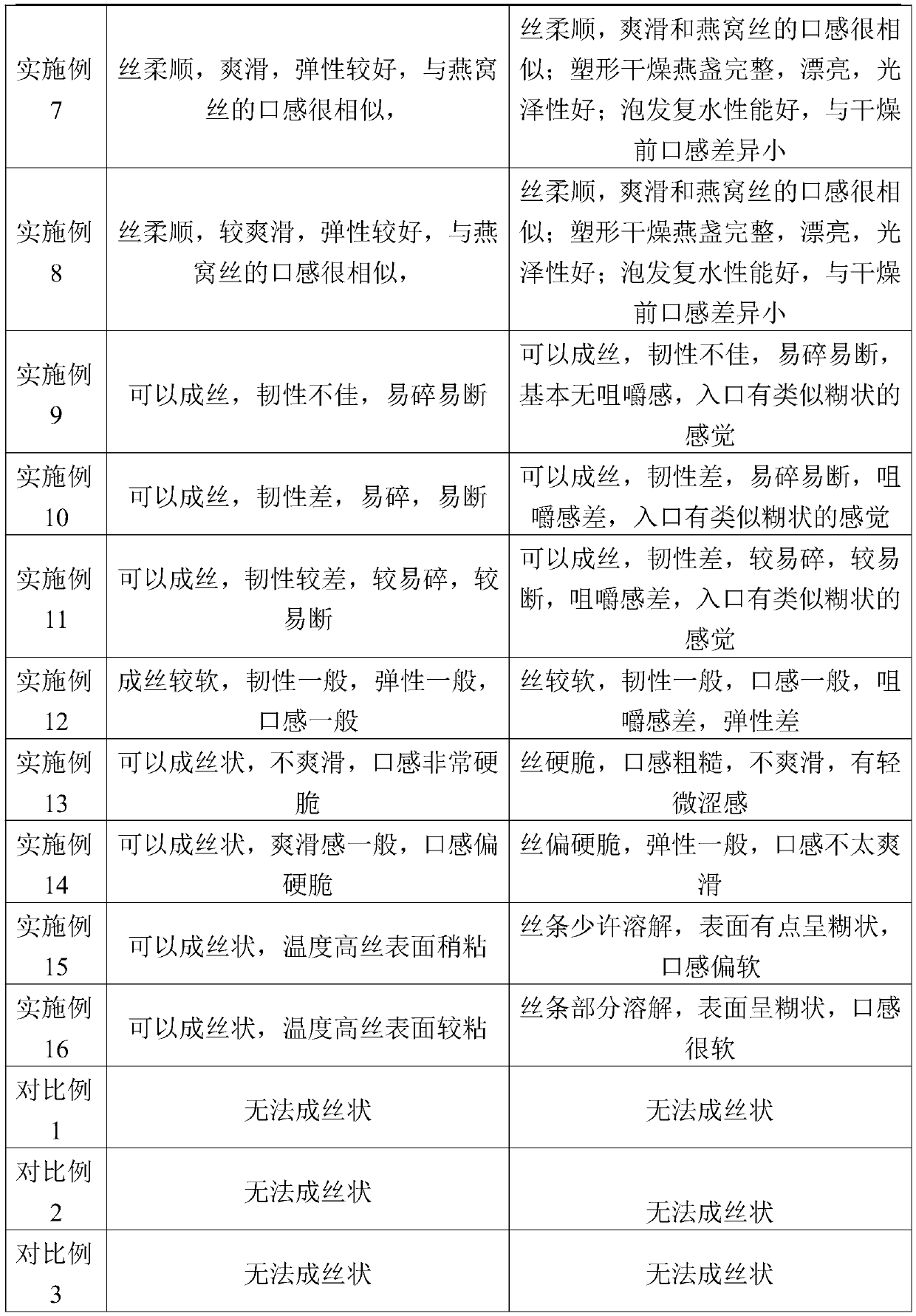

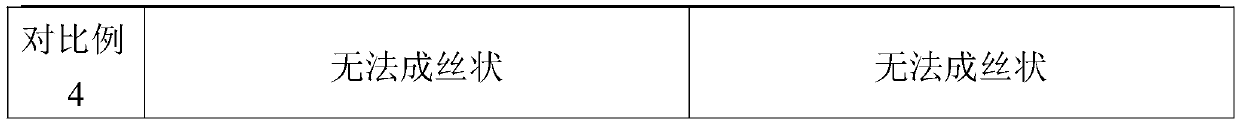

Examples

Embodiment 1

[0097] Example 1 Preparation of seaweed bird's nest bird's nest strips of the present invention

[0098] 1 Weigh 3.0 grams of sodium alginate and slowly add it to 1L of hot water at 85-90°C and stir to dissolve.

[0099] 2 Turn on the shearing machine and maintain the shearing for 15-20 minutes, keep a constant temperature of 85-90 degrees, so that the sodium alginate is fully swelled in water, and cooled to below 35°C for use.

[0100] 3 Calcium lactate solution configuration: Weigh 3.0 g of calcium lactate and 3.0 g of bird's nest acid into 500 mL of 80-90°C hot water, stir thoroughly to dissolve, and cool to below 30°C for use.

[0101] 4 Preparation of Alginate Bird's Nest: The sodium alginate solution prepared in step 2 is injected into the calcium lactate solution prepared in step 3 through a needle dropper to obtain a bird's nest strip colloid. The needle diameter is 1mm and the distance between the needle and the liquid The surface is about 10cm.

[0102] 5 Curing: Continue to ...

Embodiment 2

[0104] Example 2 Preparation of seaweed bird's nest bird's nest of the present invention

[0105] 1 Weigh 6.0 grams of sodium alginate and 15 grams of water-soluble soybean protein slowly into 1L of hot water at 85-90℃, and stir to dissolve.

[0106] 2 Turn on the shearing machine and maintain the shearing for 15-20 minutes, maintain a constant temperature of 85-90 degrees, so that the sodium alginate is fully swelled in water, cooled to room temperature, and set aside.

[0107] 3 Calcium lactate solution configuration: Weigh 3.0 g of calcium lactate and 5.0 g of bird's nest acid into 500 mL of 80-90°C hot water, stir thoroughly to dissolve, cool to room temperature, and set aside.

[0108] 4 Preparation of alginate bird's nest: pass the sodium alginate solution prepared in step 2 through the sieve and press into the calcium lactate solution prepared in step 3 to obtain alginic acid bird's nest. The sieve diameter is 1mm and the distance from the liquid surface About 10cm.

[0109] 5 T...

Embodiment 3

[0110] Example 3 Preparation of seaweed bird's nest bird's nest of the present invention

[0111] 1 Weigh 2.0 g of sodium alginate, 2.0 g of broken bird's nest (80 mesh), and 5.0 g of bird's nest acid and mix them; then slowly add them to 1L of 85-90℃ hot water, stir and mix.

[0112] 2 Calcium lactate solution configuration: Weigh 3.0 g of calcium lactate and 5.0 g of bird's nest acid into 500 mL of 80-90°C hot water, stir thoroughly to dissolve, cool to room temperature, and set aside.

[0113] 3 The remaining steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com