Ginkgo seed extract capable of relieving cough and asthma and composition, extraction method and application

An extraction method and ginkgo kernel technology are applied in the direction of drug combinations, medical preparations containing active ingredients, and pharmaceutical formulas, which can solve the problems of large doses, large toxic and side effects of ginkgo, and potential safety hazards, and achieve low liver and kidney toxicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

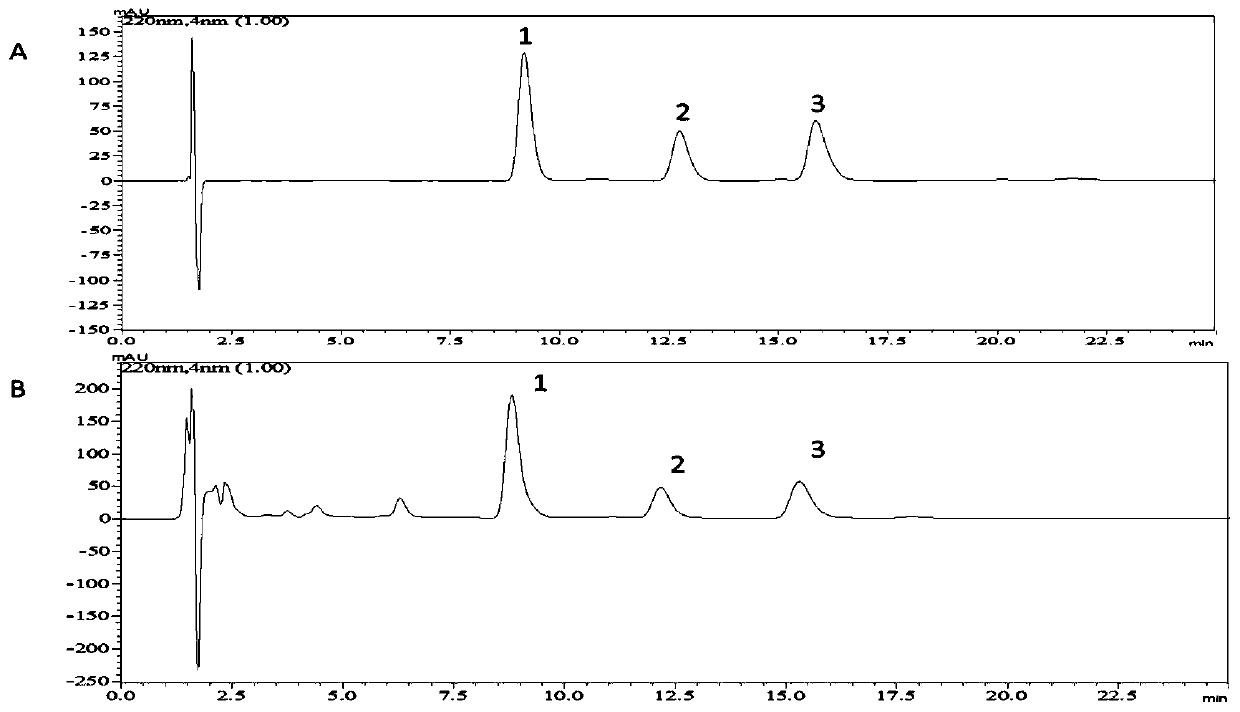

Method used

Image

Examples

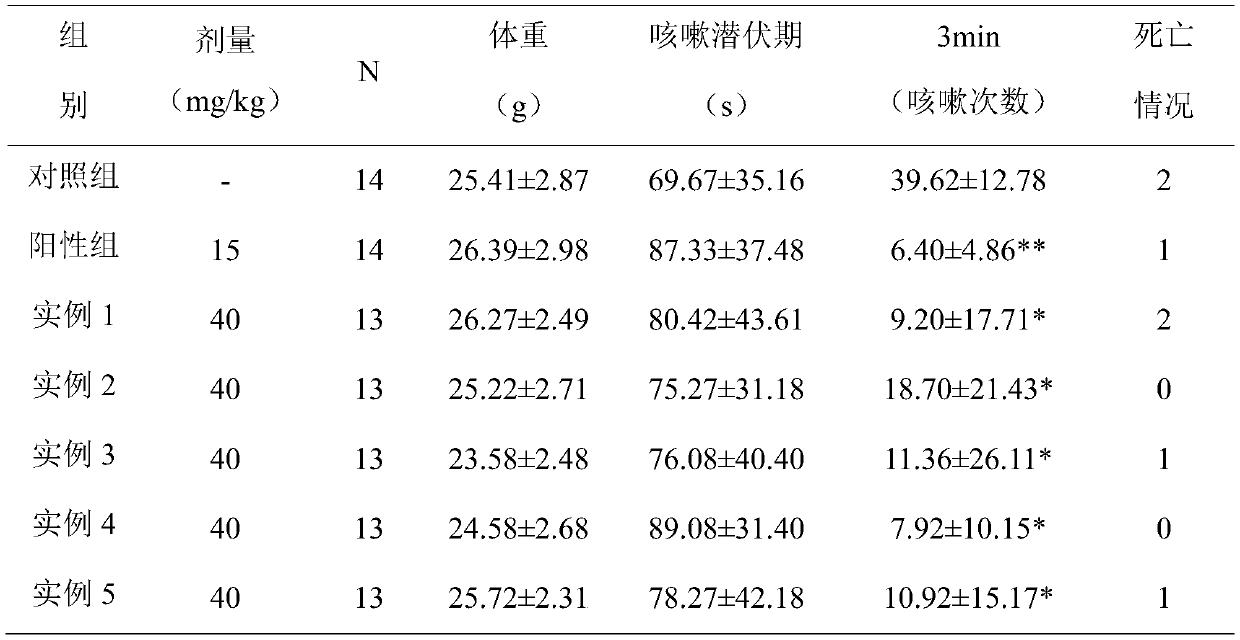

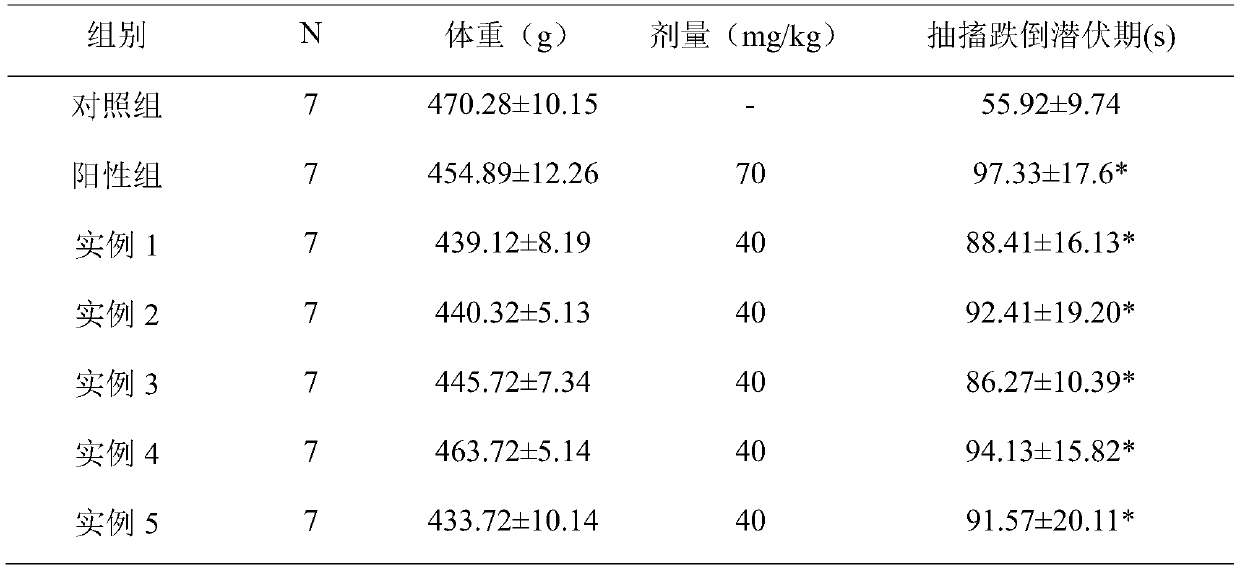

example 1

[0028] 500 kg of dried ginkgo kernels were crushed to obtain crushed ginkgo kernels. The ratio of liquid to liquid was 1:5, and 2500L of 20vol.% ethanol solution was used to heat and reflux for 1 hour to separate the filter residue and extract, and then use 2500L of 20vol.% ethanol solution to filter residue. .% ethanol solution, heated to reflux for 1 hour, separated to obtain the filter residue and the extract, and then used 2500 L of 20vol.% ethanol solution for the filter residue, heated and refluxed for 1 hour, separated to obtain the filter residue and the extract, combined three times of the extract, filtered, and the filtrate Concentrate until there is no alcohol smell, and set the volume to 500L (1.0g crude drug / 1mL extract) to obtain the initial extract. At this time, red fruit acid, N-(1-glucosyl-indole 3-acetyl)-aspartic acid The weight ratio of N-(1-glucosyl-indole 3-acetyl)-glutamic acid is about 1:2:1 in steps a and b, adjust the pH to 3 with hydrochloric acid so...

example 2

[0030] 500 kg of dried ginkgo kernels were crushed to obtain crushed ginkgo kernels. The ratio of material to liquid was 1:6, and 3000L of 35vol.% ethanol solution was used to heat and reflux for 1 hour to separate the filter residue and extract, and then use 3000L of 35vol.% ethanol solution to obtain the filter residue. .% ethanol solution, heated to reflux for 1 hour, separated to obtain the filter residue and the extract, and then used 3000 L of 35vol.% ethanol solution for the filter residue, heated and refluxed for 1 hour, separated to obtain the filter residue and the extract, combined three times of the extract, filtered, and the filtrate Concentrate until there is no alcohol smell, and set the volume to 500L (1.0g crude drug / 1mL extract) to obtain the initial extract. At this time, red fruit acid, N-(1-glucosyl-indole 3-acetyl)-aspartic acid , The weight ratio of N-(1-glucosyl-indole 3-acetyl)-glutamic acid is step a, b is about 1:2:1, adjust the pH to 3.5 with hydroch...

example 3

[0032]500 kg of dried ginkgo kernels were crushed to obtain crushed ginkgo kernels. The ratio of material to liquid was 1:7, and 3500L of 60vol.% ethanol solution was used to heat and reflux for 1 hour to separate the filter residue and extract, and then use 3500L of 60vol. .% ethanol solution, heated and refluxed for 1 hour, separated to obtain the filter residue and the extract, combined the two extracts, filtered, concentrated the filtrate to no alcohol smell, and settled the volume to 500L (1.0g crude drug / 1mL extract) to obtain the initial Liquid extraction, at this moment, the weight ratio of red fruit acid, N-(1-glucosyl-indole 3-acetyl)-aspartic acid, N-(1-glucosyl-indole 3-acetyl)-glutamic acid For step a, b is about 1:2:1, adjust the pH to 4 with hydrochloric acid solution, centrifuge at 6000r for 5min, take the upper layer of liquid medicine, take 50 kg of NKA-2 macroporous resin (wet mass, about 75L), and use wet method Slowly load it into the column (diameter-to-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com