Workshop glue circulating system of paste-manufacturing technology

A circulatory system and glue technology, applied to the surface coating liquid device, mixer with rotating stirring device, mixer, etc., can solve the problems affecting the viscosity of glue, increase the defect rate, quality problems, etc., and achieve the reduction of glue Coagulation, improve the bonding effect, reduce the effect of defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

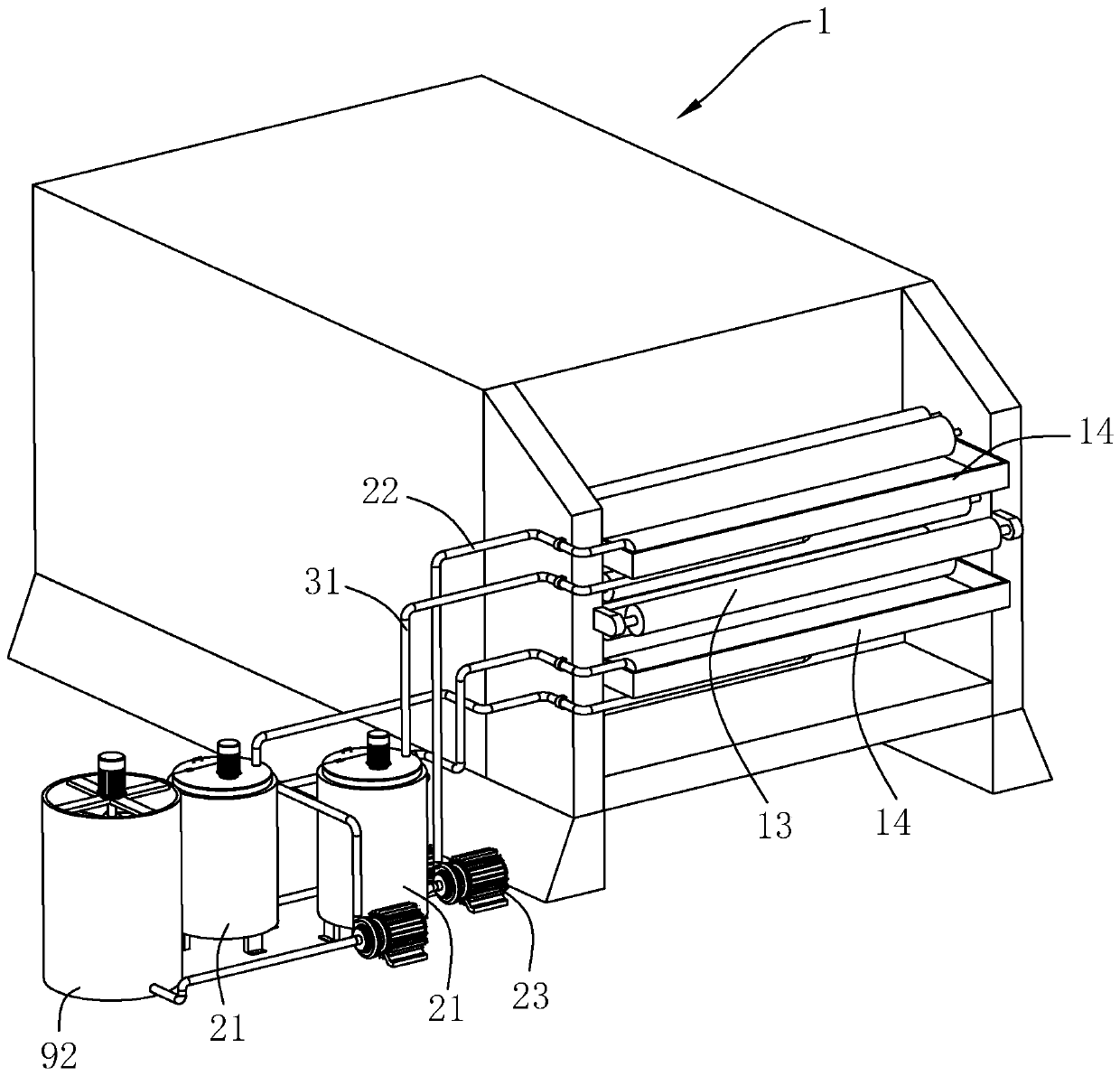

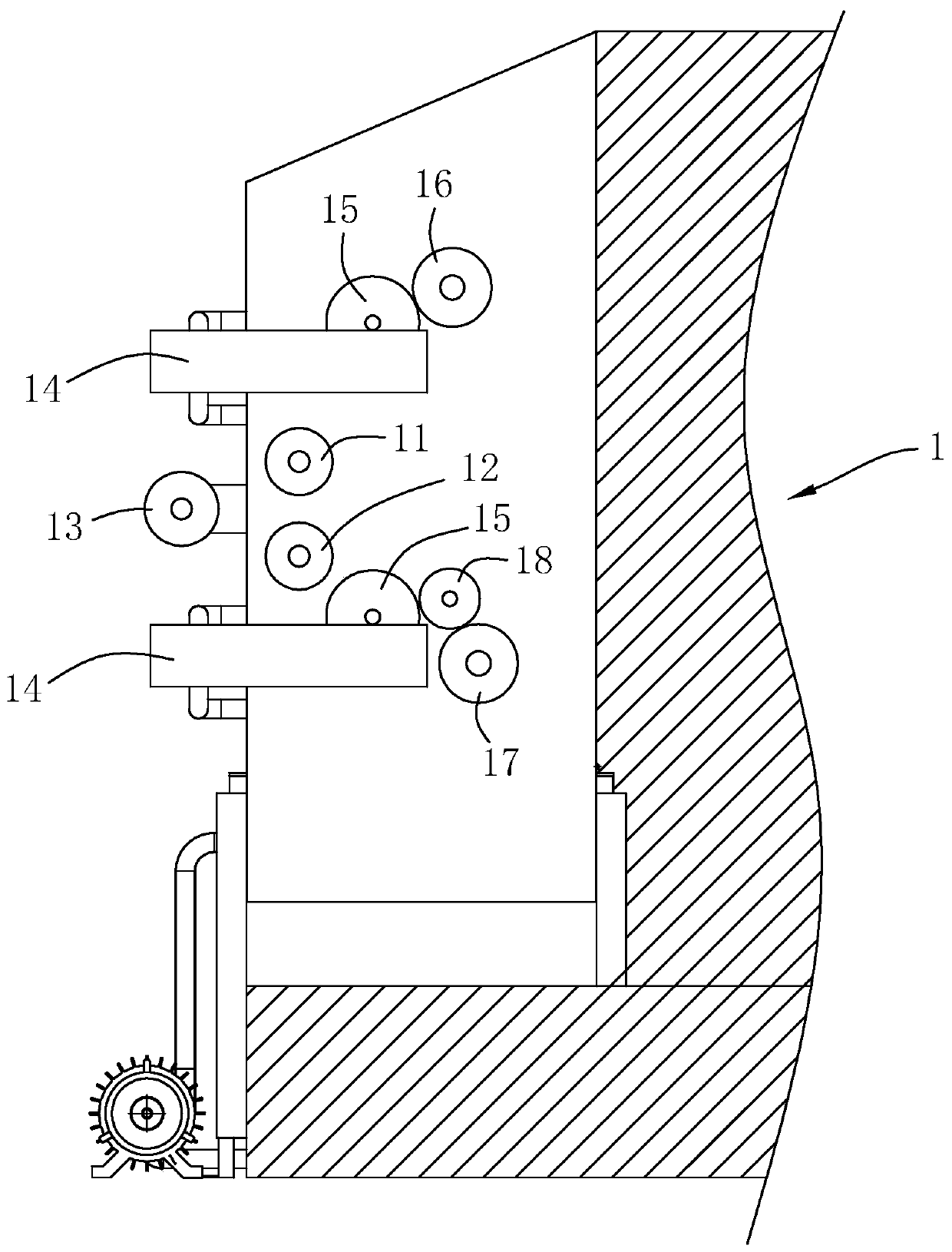

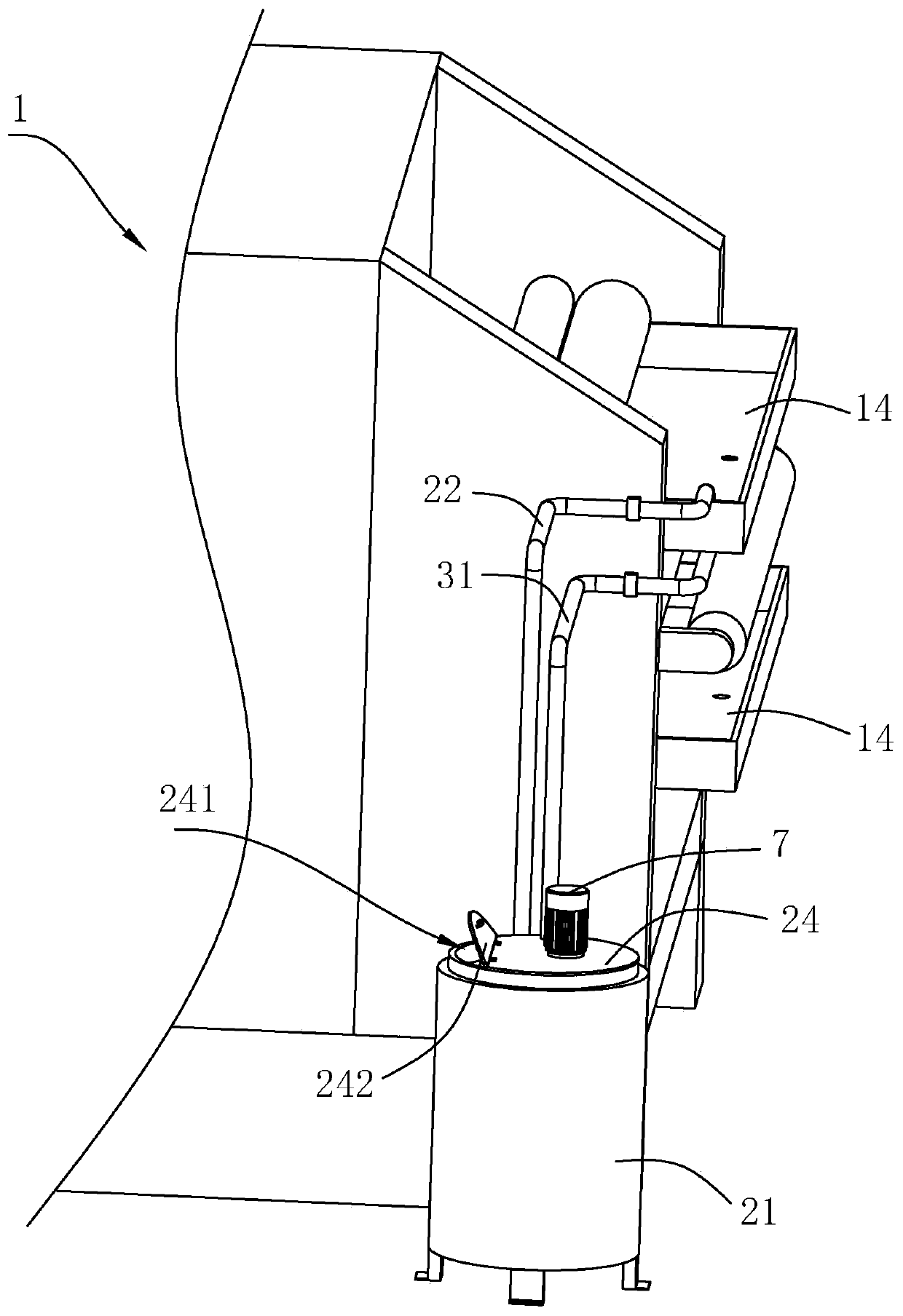

[0035] A workshop glue circulation system for paste making process, such as figure 1 and figure 2 As shown, a corrugating machine 1 is included, and the corrugating machine 1 includes a corrugating forming mechanism. The corrugating forming mechanism includes an upper corrugating roller 11, a lower corrugating roller 12 and a tension roller 13, and the base paper passes between the upper corrugating roller 11 and the lower corrugating roller 12, The tension roller 13 adjusts the tension of the conveying base paper, and the upper corrugating roller 11 and the lower corrugating roller 12 heat-press the base paper into corrugated corrugated corrugated paper with a corrugated middle layer.

[0036] The corrugating machine 1 also includes a gluing mechanism. In this embodiment, there are two groups of gluing mechanisms. The two groups of gluing mechanisms are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com