Device for installing single-blade hydraulic swing oil cylinder

A technology of hydraulic swing and installation device, applied in the field of hydraulic equipment, can solve problems such as the failure of oil cylinder to work normally, and achieve the effect of reducing failure to work normally, wide application range, and ensuring the coaxiality of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

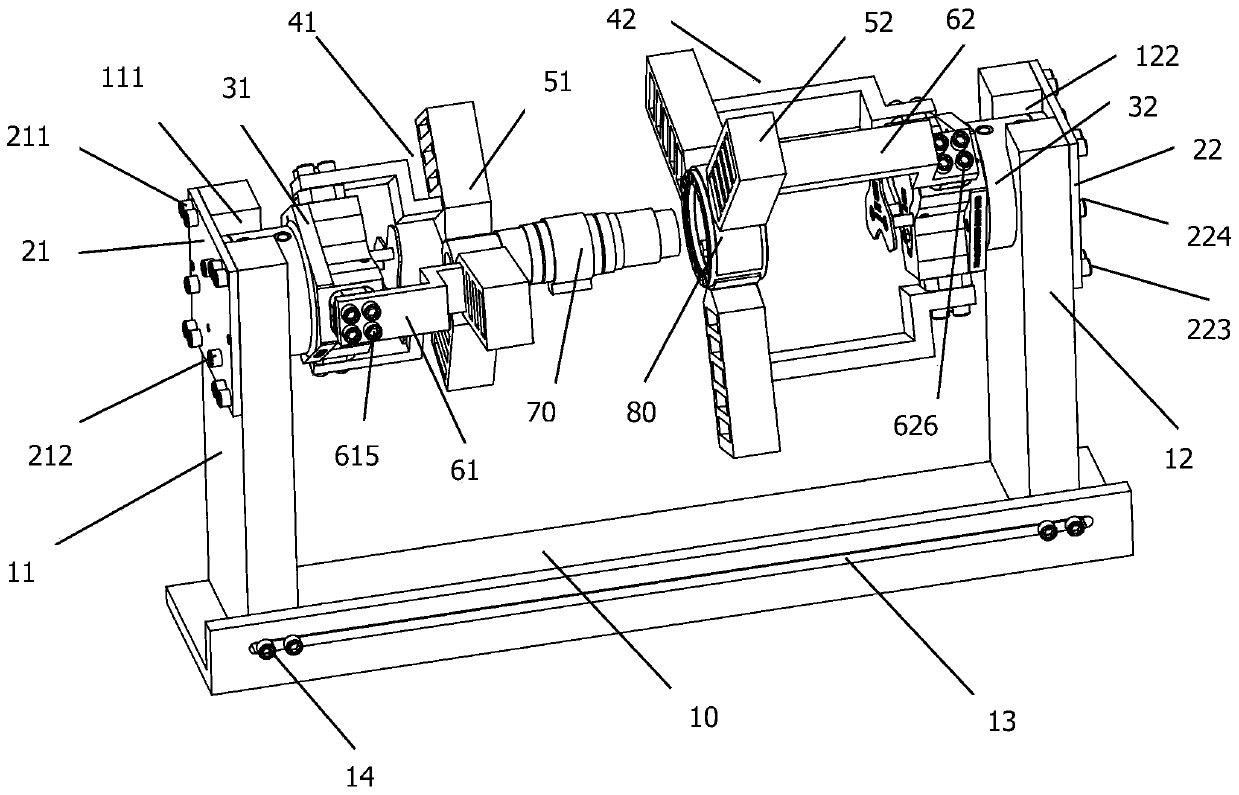

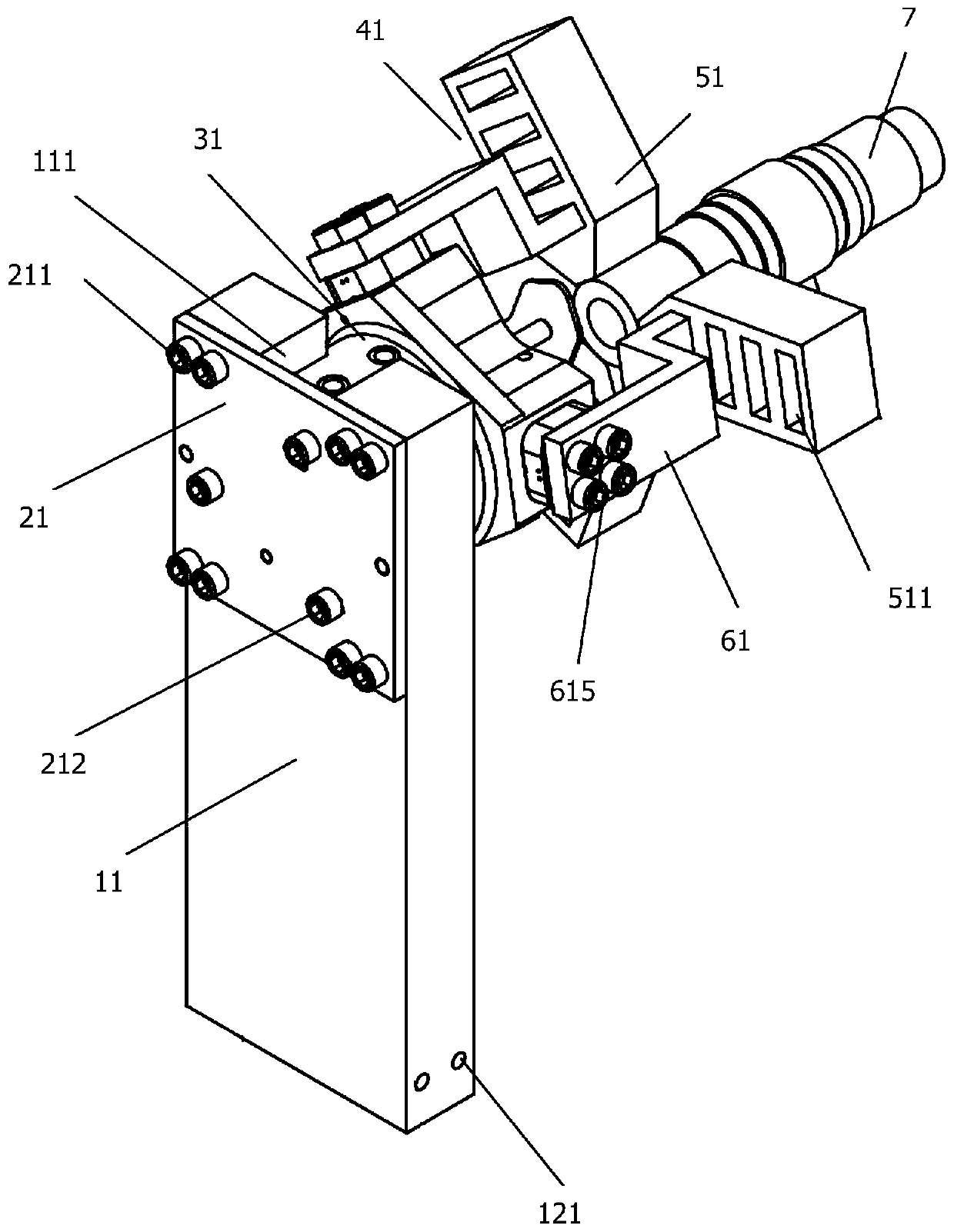

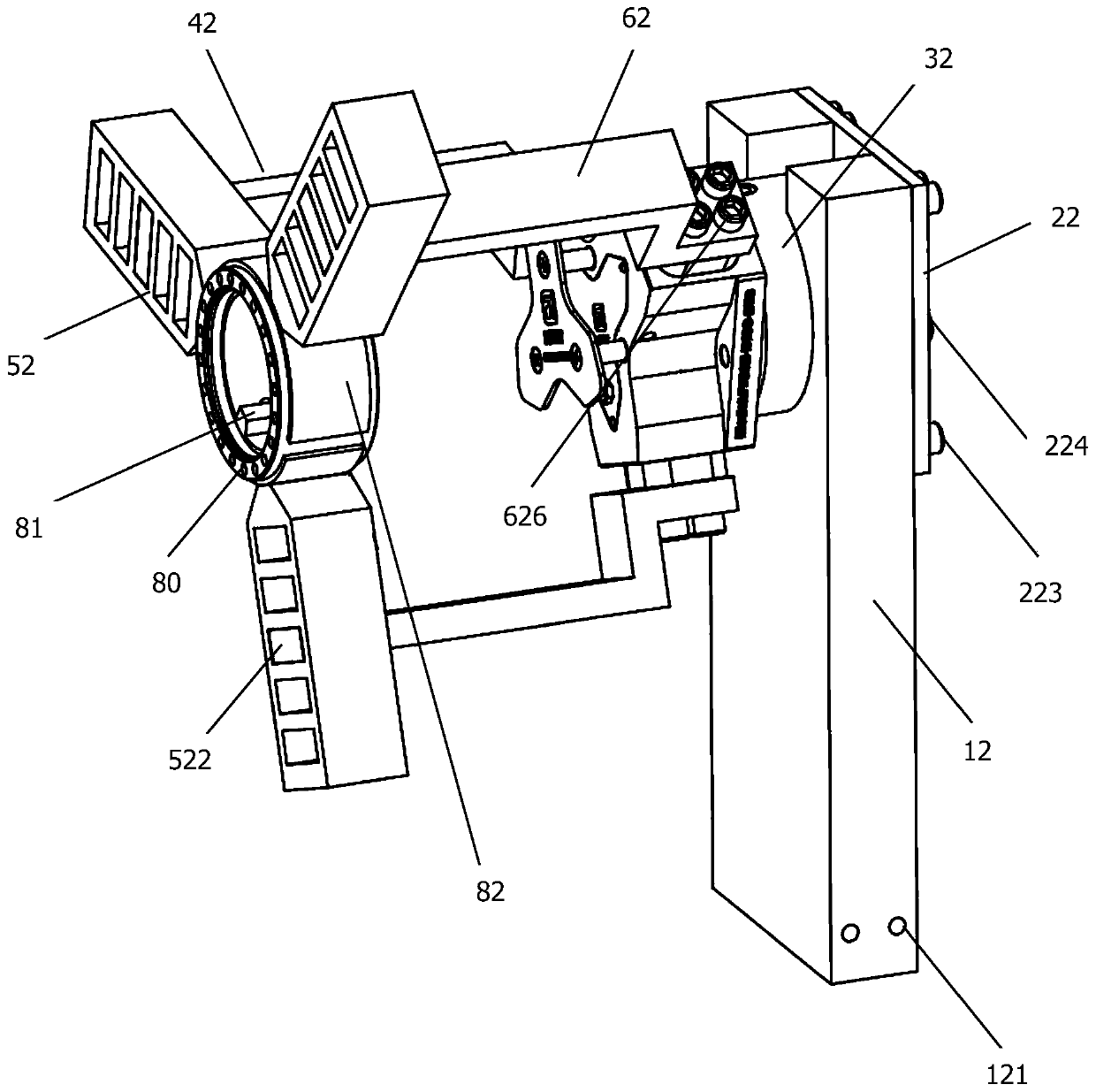

[0039] Such as Figure 1 to Figure 3 , a single-blade hydraulic swing cylinder installation device, including a base plate 10, a first vertical plate 11, a second vertical plate 12, a first connecting plate 21, a second connecting plate 22, a first fixing seat 31, and a second fixing seat 32 , a first coaxial assembly 41, a second coaxial assembly 42, a rotor 70, and a cylinder 80; the first coaxial assembly 41 includes a plurality of first coaxial brackets 61 and a plurality of first coaxial blades 51, so The second coaxial assembly 42 includes a plurality of second coaxial brackets 62 and a plurality of second coaxial blades 52;

[0040] The bottom plate 10 is L-shaped, and the side of the bottom plate 10 is provided with a chute 13, and a plurality of adjustment pins 14 are arranged in the chute 13; end, the bottom of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com