Small transfer device capable of collecting scrap iron for machining equipment transformation

A technology of mechanical processing and transfer device, which is applied in transportation and packaging, motor vehicles, multi-axis trolleys, etc., can solve the problems of unstable transfer device, high working intensity, easy sliding safety, etc., so as to reduce potential safety hazards and reduce work intensity. , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

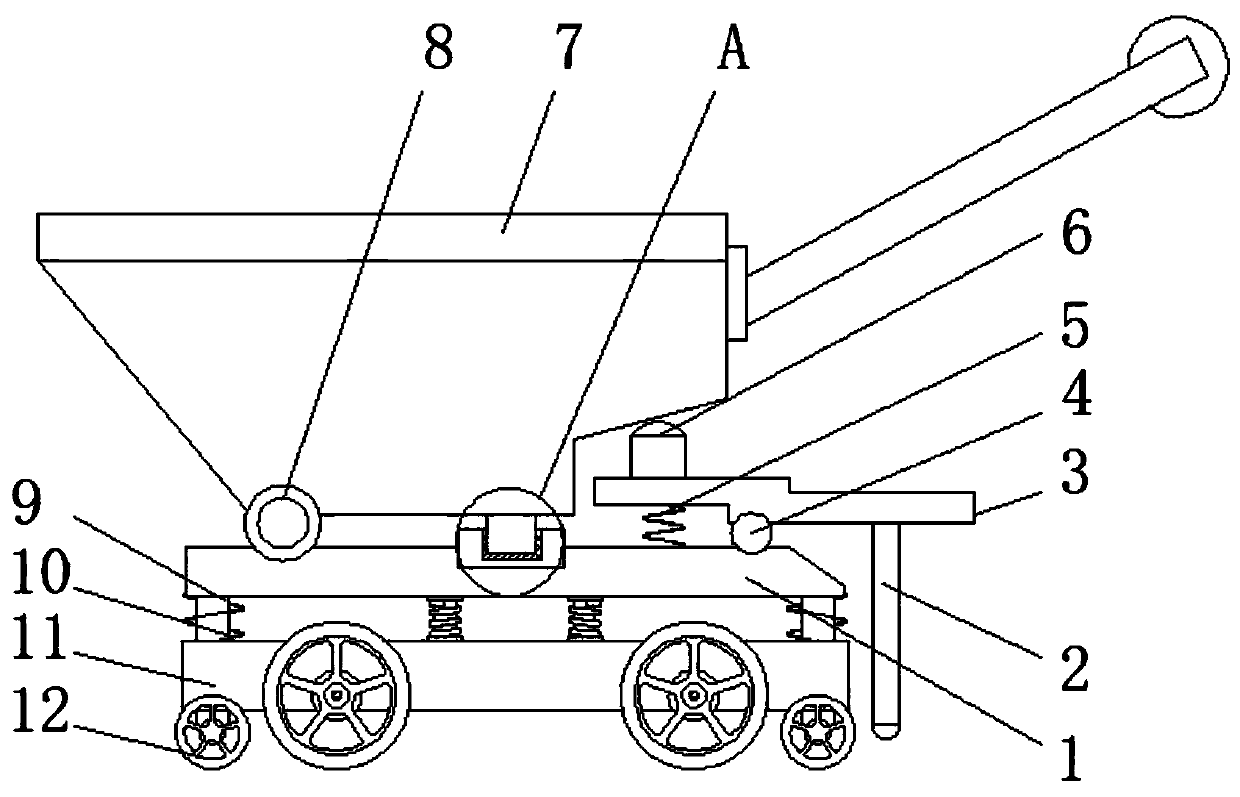

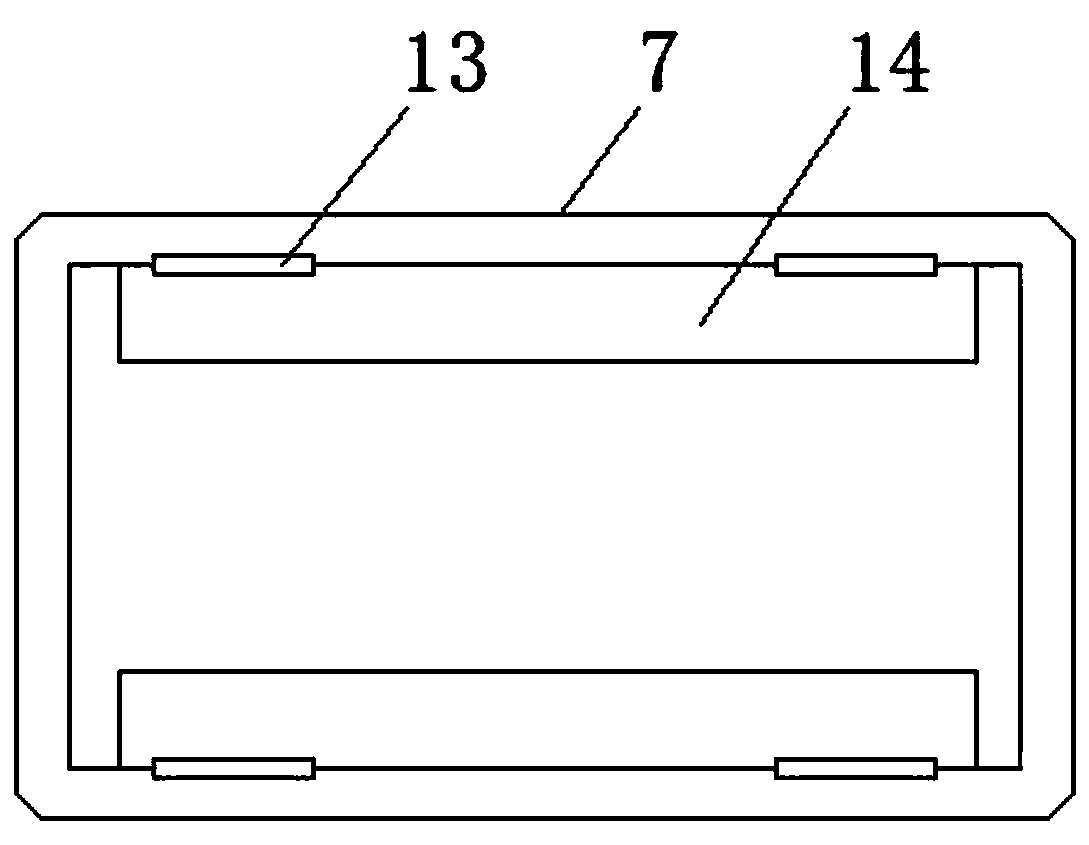

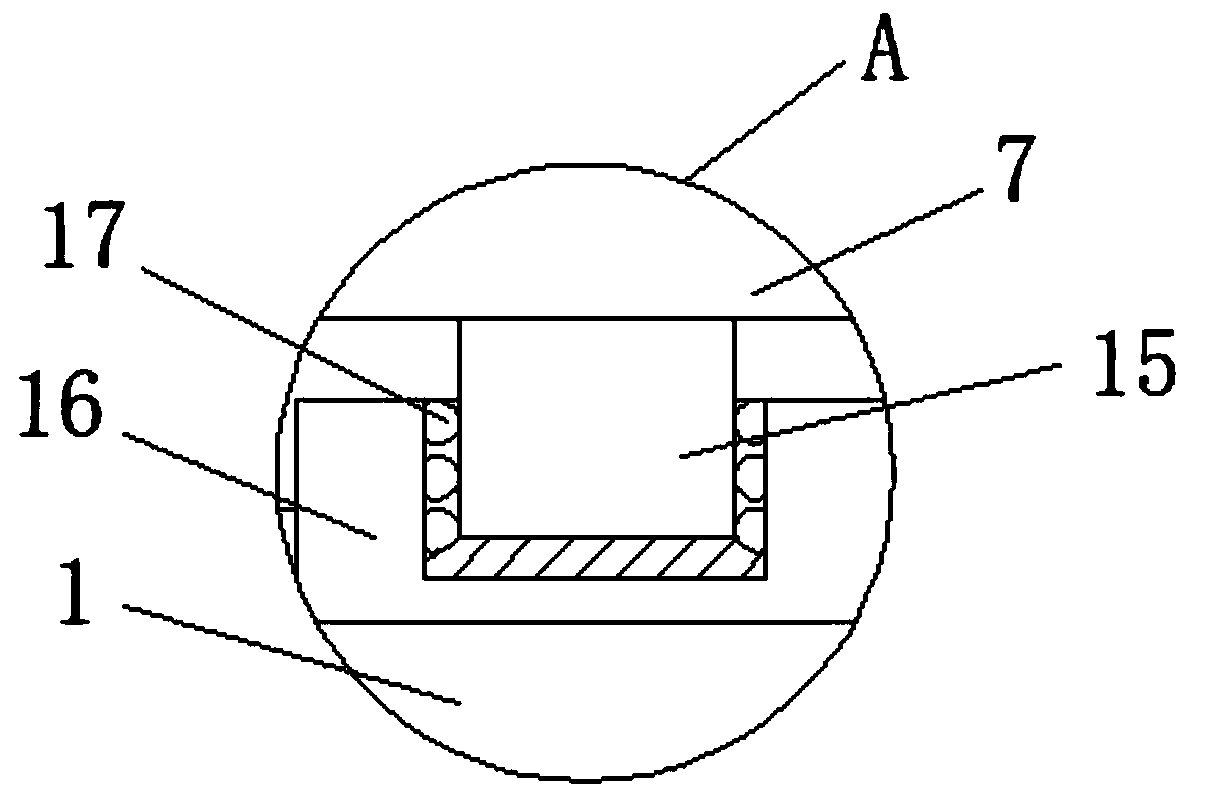

[0023] Such as Figure 1-3 As shown, the present invention provides a technical solution: a small transfer device for the transformation of mechanical processing equipment that can collect scrap iron, including a main base 1, the upper surface of the main base 1 is fixedly connected with a limited groove block 16, an insert 15 One end of one end is clamped in the limit groove block 16, and the inner wall of the limit groove block 16 is provided with several protrusions 17, and the bottom end of the transfer box 7 can be limited and fixed by the limit groove block 16 in conjunction with the insert block 15, And through the action of several bumps 17, the friction force between them can be increased to ensure that the transfer case 7 is structurally stable during the transfer process, not easy to loosen, and does not affect the rotation of the transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com