Curtain wall glass lifting transportation platform

A technology for transporting platforms and glass, which is applied in the direction of transport and packaging, walls, and load-hanging components, etc. It can solve the problems of cumbersome procedures and low installation efficiency, and achieve the effect of eliminating manual handling up and down, eliminating operating procedures, and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

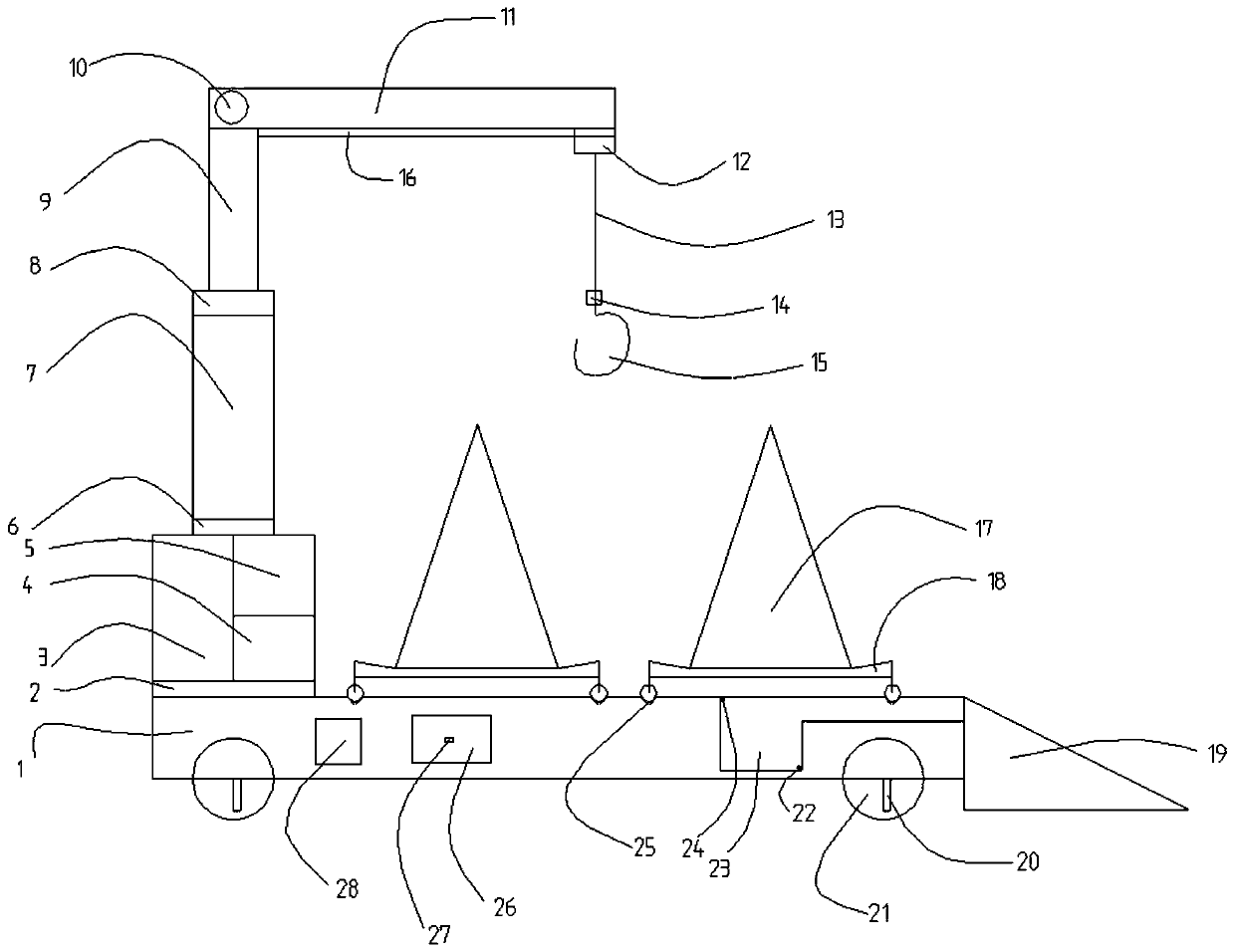

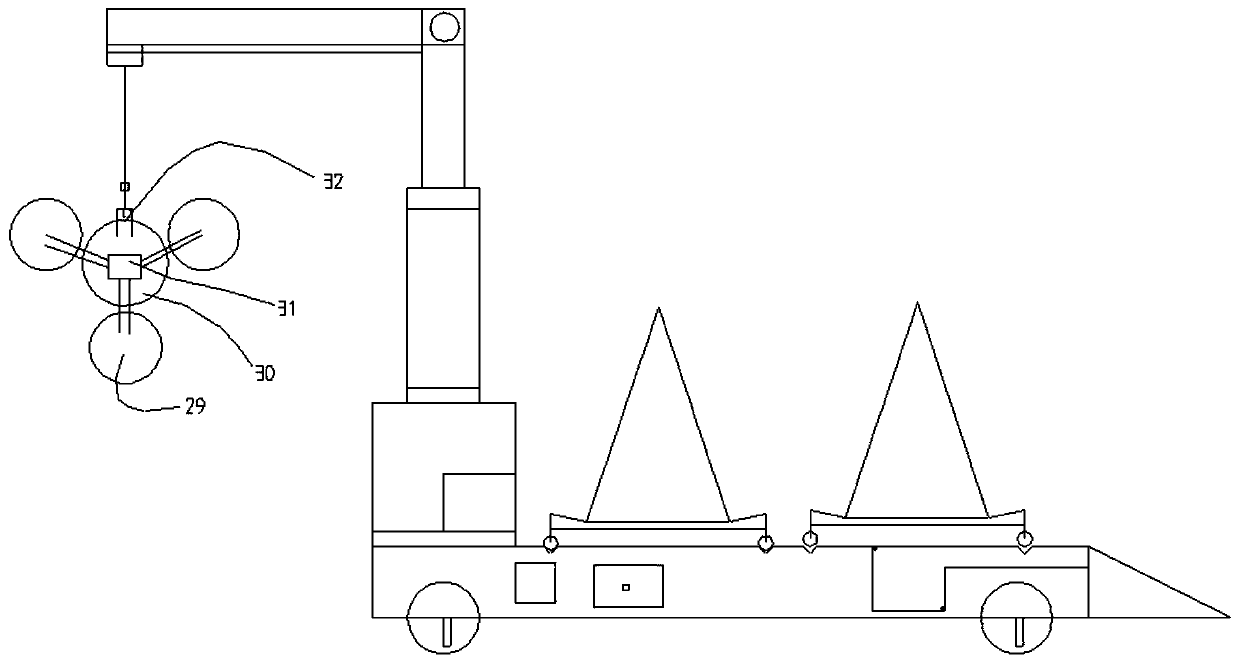

[0023] A curtain wall glass hoisting transportation platform, comprising a transportation platform and a hoisting system.

[0024] Such as Figure 1 ~ Figure 2 As shown, the transport platform includes a lockable electric transport vehicle 1 and a number of curtain wall glass loading components. The transport vehicle 1 includes a vehicle-mounted power supply 26 and a transmission device 28. The transmission device 28 is an electric vehicle motor of the prior art. The power supply 26 is used as the power source of the electric vehicle motor. The electrically driven transport trolley is no longer described as a mature technology. In this embodiment, the transportation wheel 21 is preferably a rubber wheel with a braking device 20, and the rubber wheel can be locked by the braking device 20 after the transportation vehicle 1 reaches a designated position. The transport vehicle 1 is provided with a limit assembly, and the limit assembly is used to limit the placement of the curt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com