Preparation method of acetamidine hydrochloride

A technology of acetamidine hydrochloride and acetonitrile, applied in the field of preparation of acetamidine hydrochloride, can solve the problems of low production process yield and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

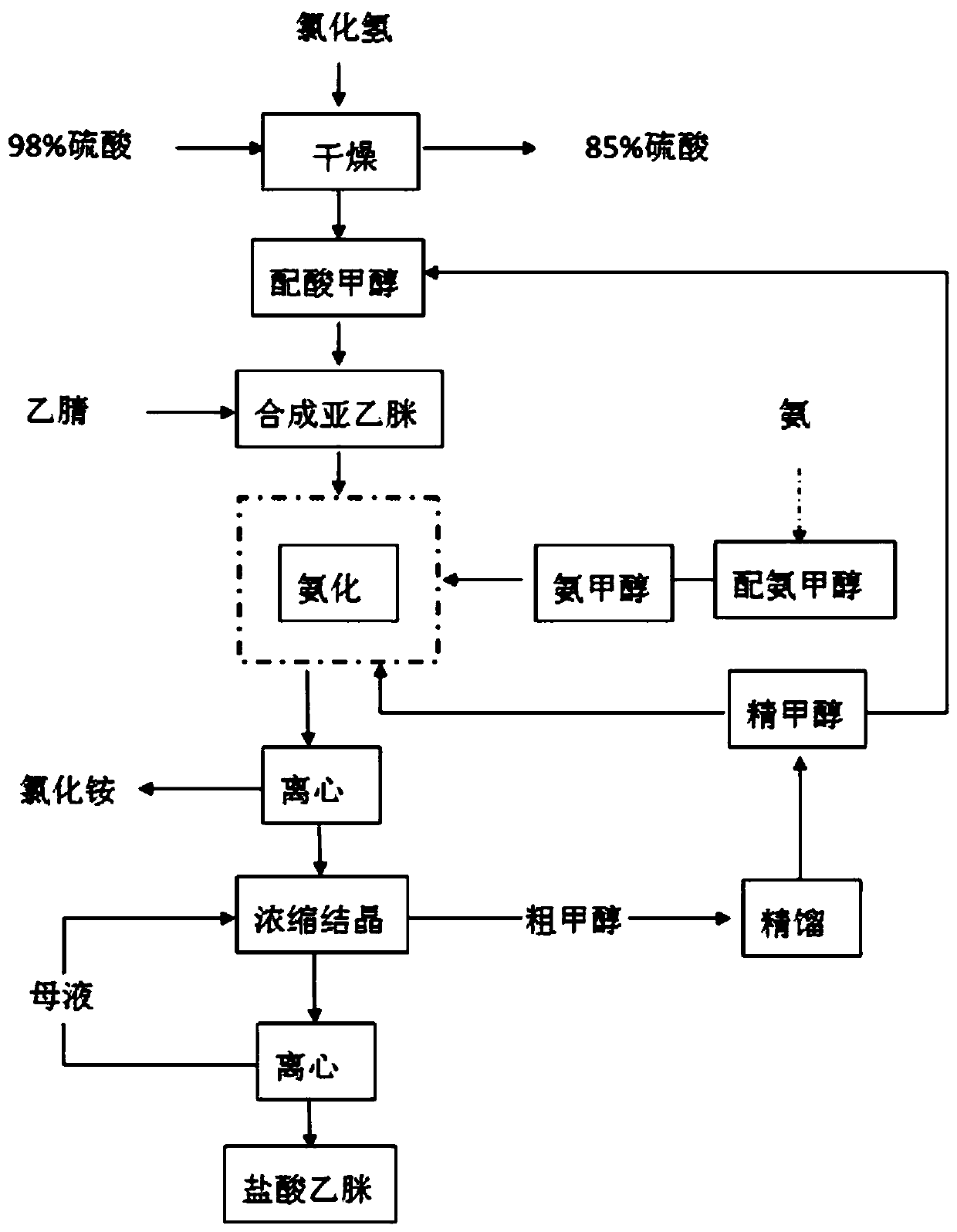

[0021] The embodiment of the present invention discloses a kind of preparation method of acetamidine hydrochloride, as shown in the figure, comprises the following steps:

[0022] a. Hydrogen chloride is passed into the kettle that has the concentrated sulfuric acid to dry, then forms acid methanol with methanol, and the concentration of acid methanol is 46% (w / w);

[0023] b. Put the acid methanol into the reaction kettle, slowly add acetonitrile dropwise through the metering tank, so that the temperature is controlled at 9°C; after adding the acetonitrile, keep it at about 20°C for 5 hours to synthesize acetamidine;

[0024] c. After the ethyleneamidine synthesis is completed, open the reactor jacket brine, and add a certain amount of methanol to make the temperature of the material drop to -5°C, then add ammonia methanol in the reactor, and the concentration of ammonia methanol is 17% (w / w ), add slowly in the early stage to control the temperature at 0~-5°C, when 1 / 3 of th...

Embodiment 2

[0027] Embodiments of the present invention disclose a kind of preparation method of acetamidine hydrochloride, comprising the following steps:

[0028] a. Hydrogen chloride is passed into the still that has the concentrated sulfuric acid to dry, then forms acid methanol with methanol, and the concentration of acid methanol is 46.8% (w / w);

[0029] b. Put the acid methanol into the reaction kettle, slowly add acetonitrile dropwise through the metering tank, so that the temperature is controlled at 10°C; after adding the acetonitrile, keep it at about 25°C for 6 hours to synthesize acetamidine;

[0030] c. After the ethyleneamidine synthesis is completed, open the reactor jacket brine, and add a certain amount of methanol to make the temperature of the material drop to -5°C, then add ammonia methanol in the reactor, and the concentration of ammonia methanol is 16% (w / w ), add slowly in the early stage to control the temperature at 0~-5°C, when 1 / 3 of the amount is added, when p...

Embodiment 3

[0033] Embodiments of the present invention disclose a kind of preparation method of acetamidine hydrochloride, comprising the following steps:

[0034] a. Hydrogen chloride is passed into the kettle that has the concentrated sulfuric acid to dry, then forms acid methanol with methanol, and the concentration of acid methanol is 48% (w / w);

[0035] b. Put the acid methanol into the reaction kettle, slowly add acetonitrile dropwise through the metering tank, so that the temperature is controlled at 11°C; after adding the acetonitrile, keep it at about 28°C for 7 hours to synthesize acetamidine;

[0036] c. After the synthesis of ethyleneamidine is completed, open the reactor jacket brine, and add a certain amount of methanol to make the temperature of the material drop to -5 ° C, then add ammonia methanol in the reactor, and the concentration of ammonia methanol is 15% (w / w ), add slowly in the early stage to control the temperature at 0~-5°C, when 1 / 3 of the amount is added, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com