Epoxy terrace construction robot

A technology of epoxy flooring and robots, applied in the field of painting, can solve problems such as low efficiency, high cost, and repetitive labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

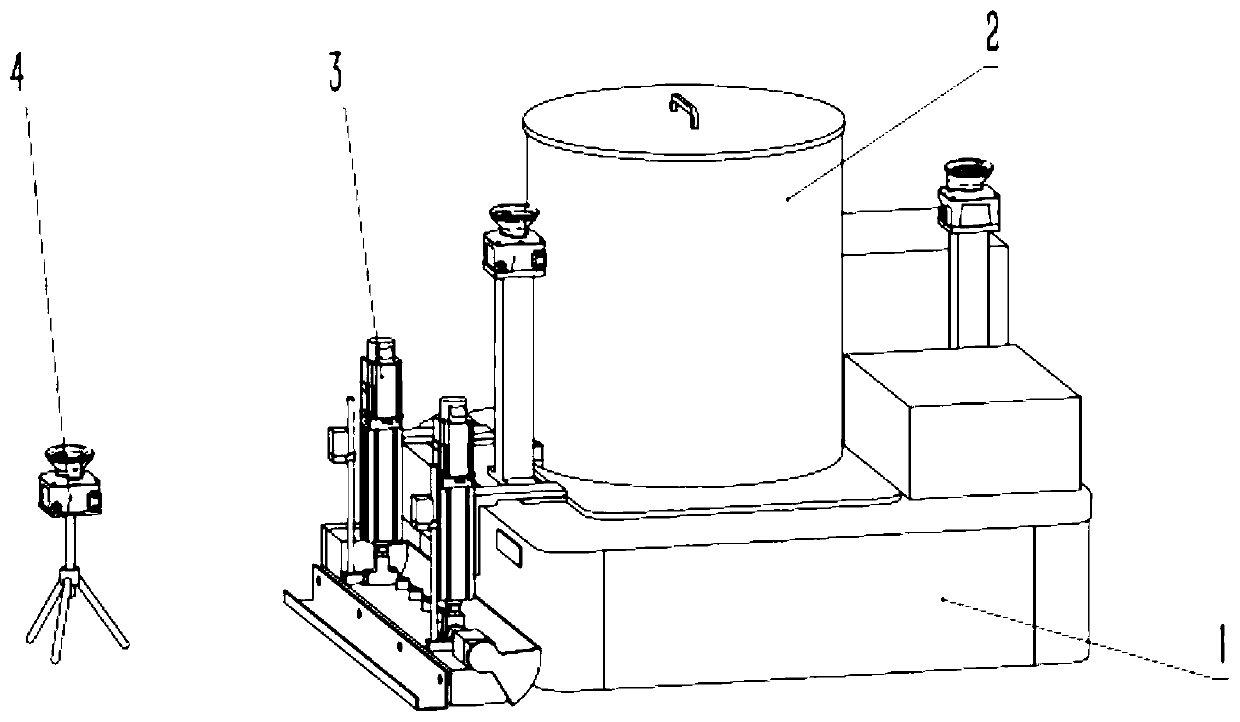

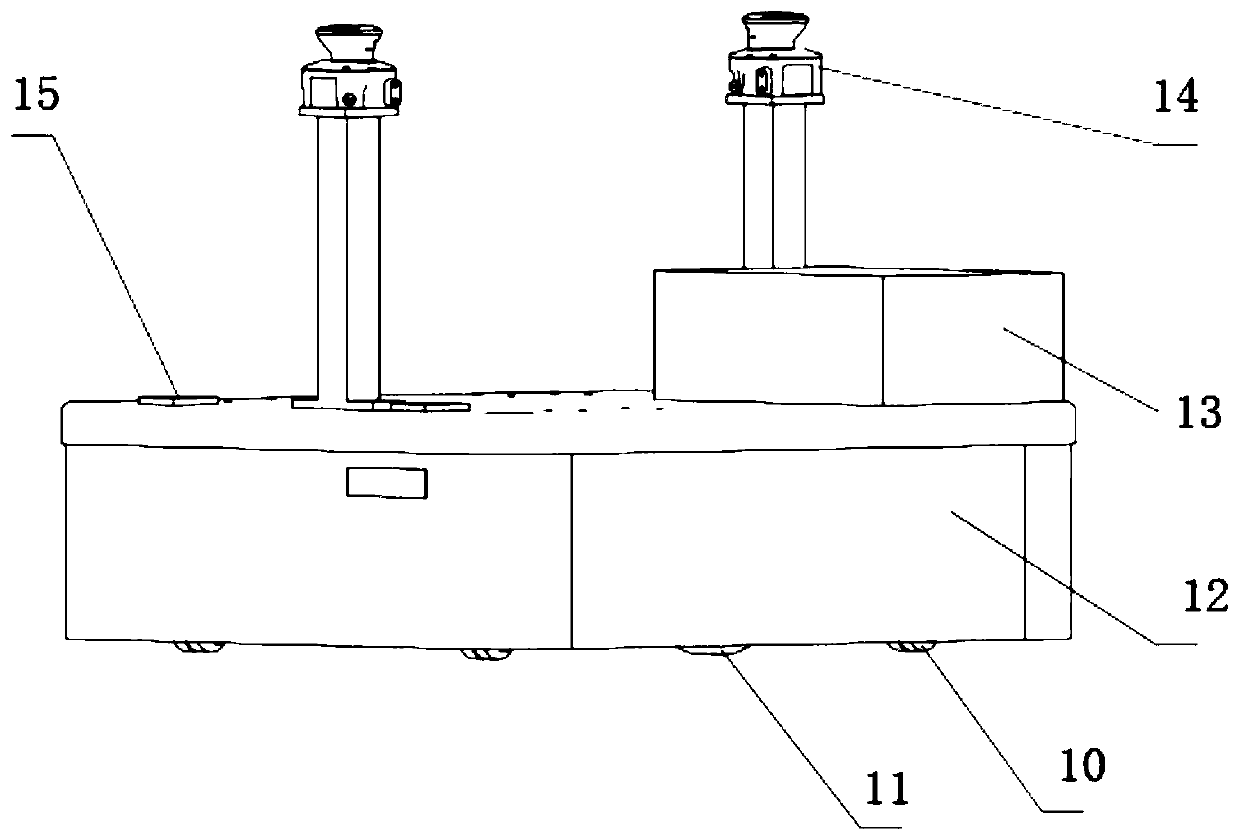

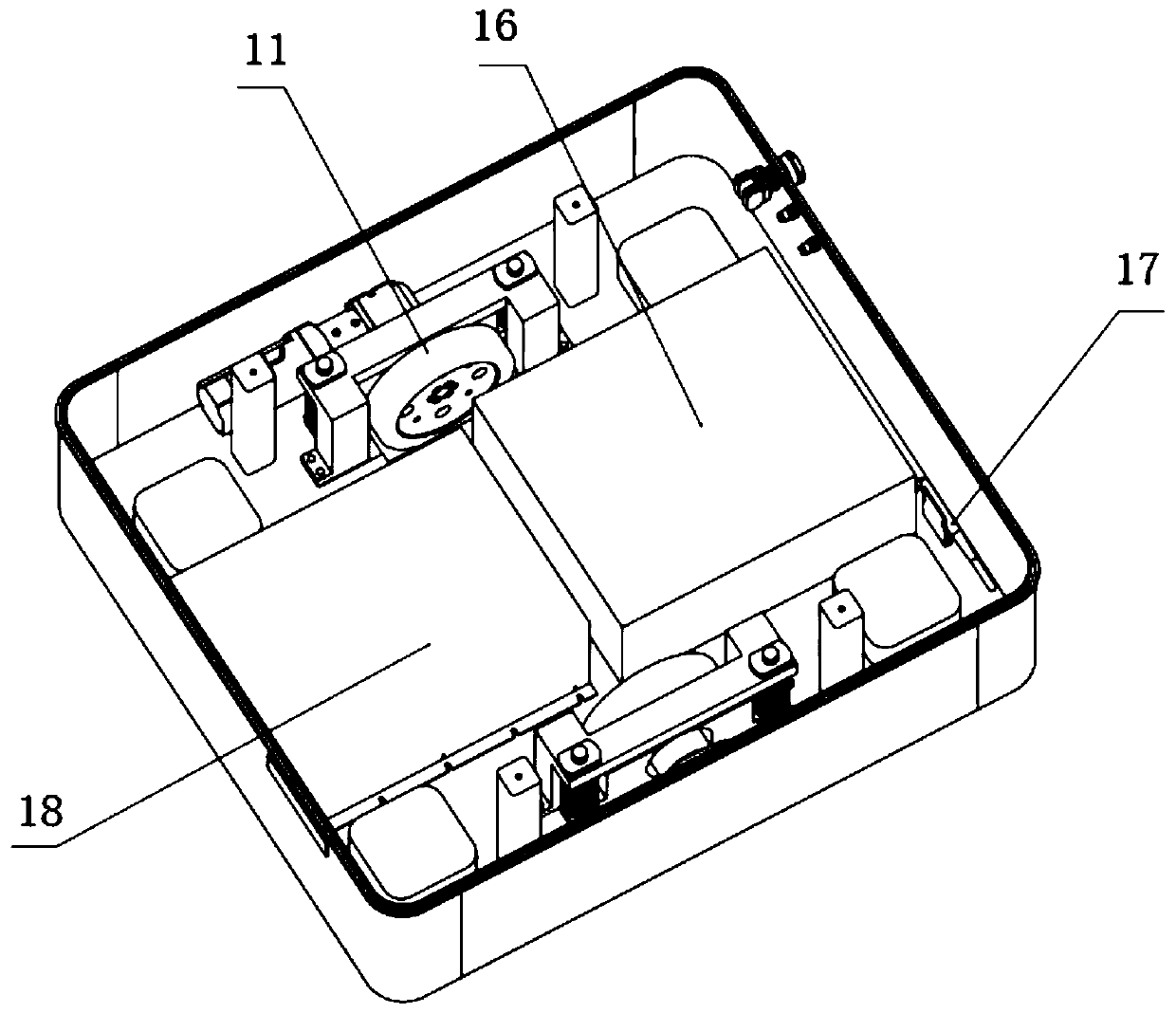

[0030] like figure 1 An epoxy floor construction robot shown includes a robot-driven chassis 1, a feeding device 2, an intermediate coating assembly 3, a primer surface coating assembly 5, a bottom spray surface spray assembly 6, a feeding device 2, and an intermediate coating assembly 3. Including the primer and surface coating assembly 5, the bottom spray surface spray assembly 6 is installed on the robot driving chassis 1, and is electrically connected with the robot driving chassis 1. The robot-driven chassis 1 is the drive, navigation, control, planning, and power supply components of the epoxy floor construction robot, and has the functions of walking, path planning, navigation, coordinated control, power supply and distribution, and the like. The feeding device 2 is used to feed and control the feeding for the epoxy floor construction robot. The feeding device 2 is used to load the spraying material. The feeding device 2 is installed on the robot driving chassis 1 and i...

Embodiment 2

[0043] A kind of epoxy floor construction robot as shown in embodiment 1, its difference is only, one or more in the intermediate coating assembly 3, the primer surface coating assembly 5, the bottom spray surface spray assembly 6 are installed on the robot drive chassis 1 indivual. By installing the intermediate coating assembly, primer surface coating assembly, and bottom spraying surface spraying assembly on the robot-driven chassis, there is no need to replace the spraying parts when changing the spraying material or process, ensuring the continuity and convenience of material spraying and saving replacement time.

Embodiment 3

[0045] An epoxy floor construction robot as shown in Embodiment 1, the only difference is that the epoxy floor construction robot also includes a laser emitter assembly 4 for detecting and feeding back the flatness of the bottom surface, and the laser emitter assembly 4 Placed in front of the running track of the epoxy floor construction robot. By setting the laser emitter assembly 4, the epoxy floor construction robot can automatically complete the adjustment according to the flatness of the bottom surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com