Ground stress extending, renovating and yield-increasing method for oil-gas well

An in-situ stress, oil and gas well technology, which is applied in the fields of earthwork drilling, wellbore/well components, and production fluids, etc., can solve problems such as the difficulty in effectively producing thermal recovery technology, restricting the efficient development of heavy oil resources, and reducing oil well blockage and production. Achieve the effect of improving the seepage environment around the well, optimizing the utilization of water sources, and reducing pressure penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0036] Taking Well X of PetroChina Xinjiang Oilfield as the implementation object, the in-situ stress expansion, reconstruction and production increase method of the present invention is used for construction, and the specific steps are as follows:

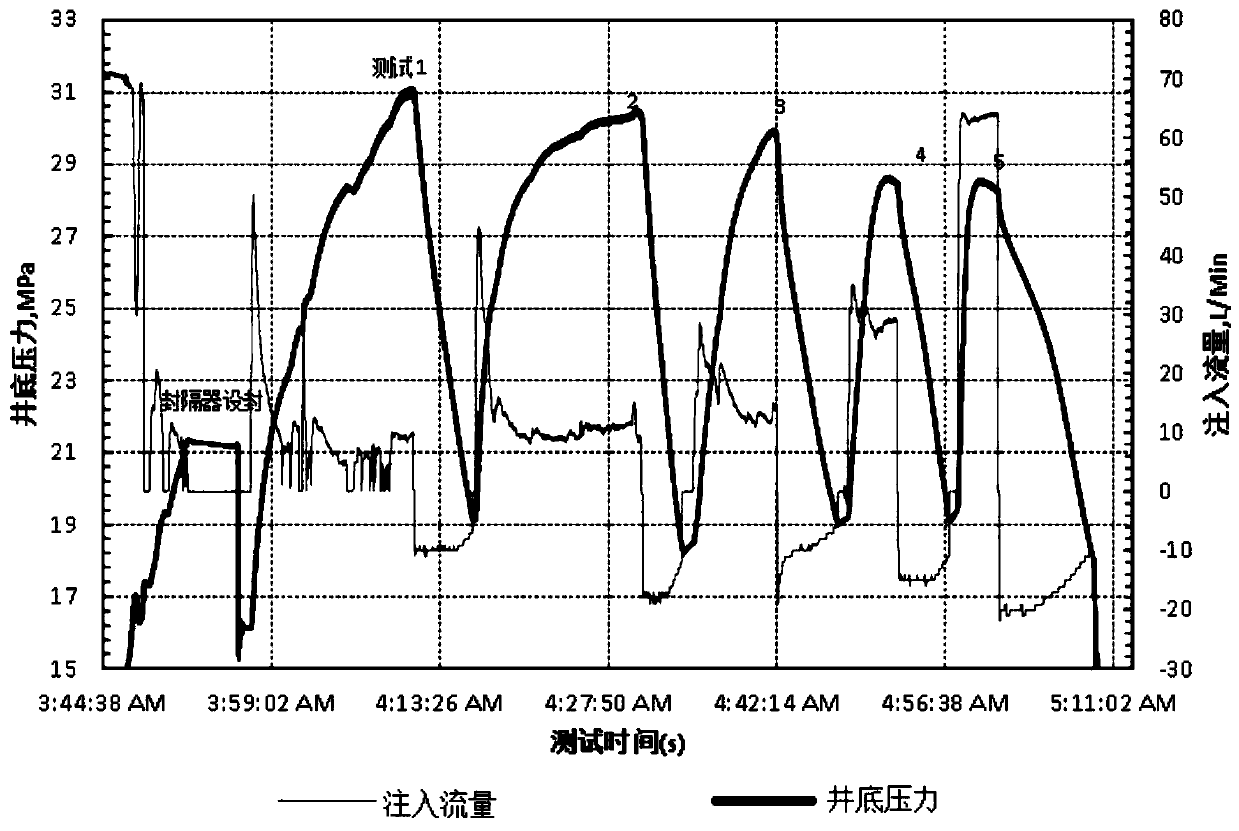

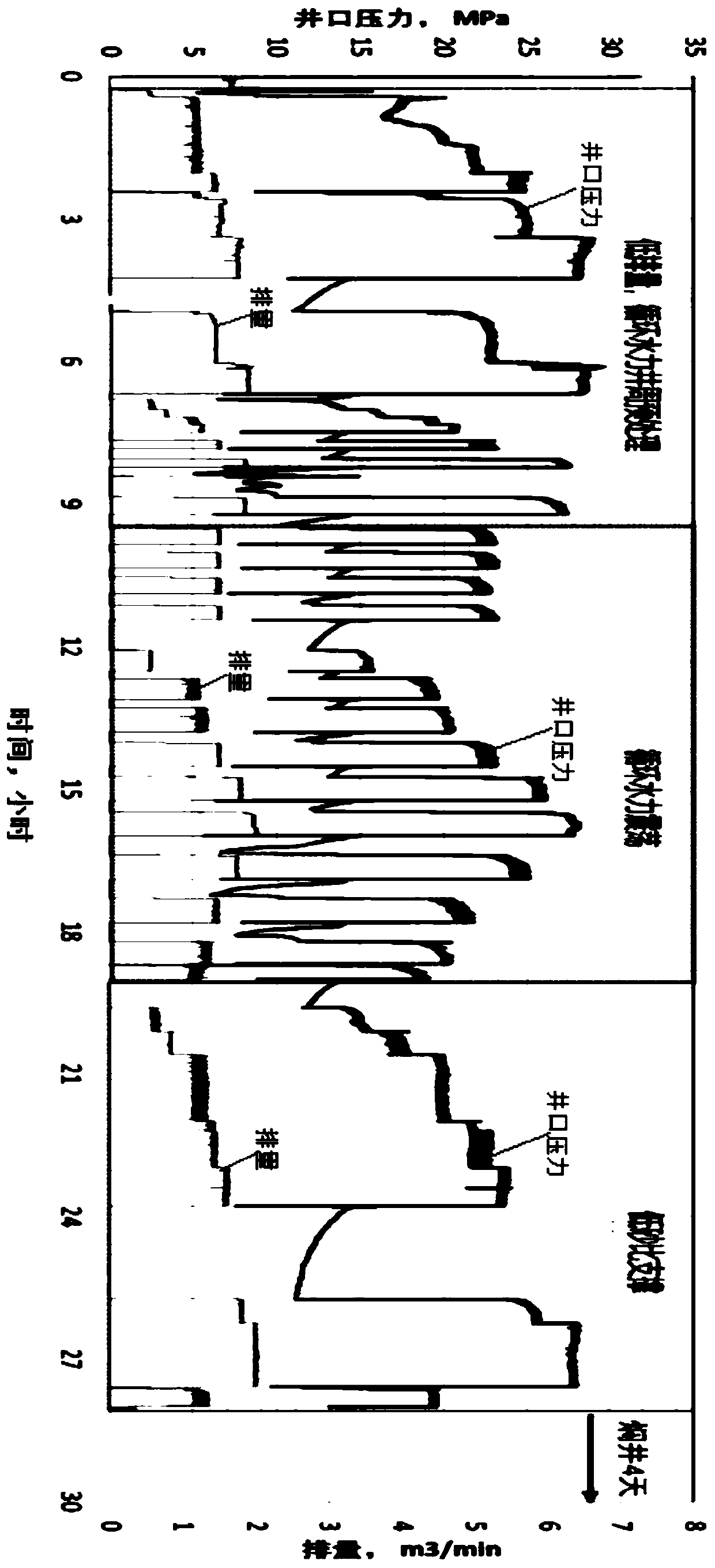

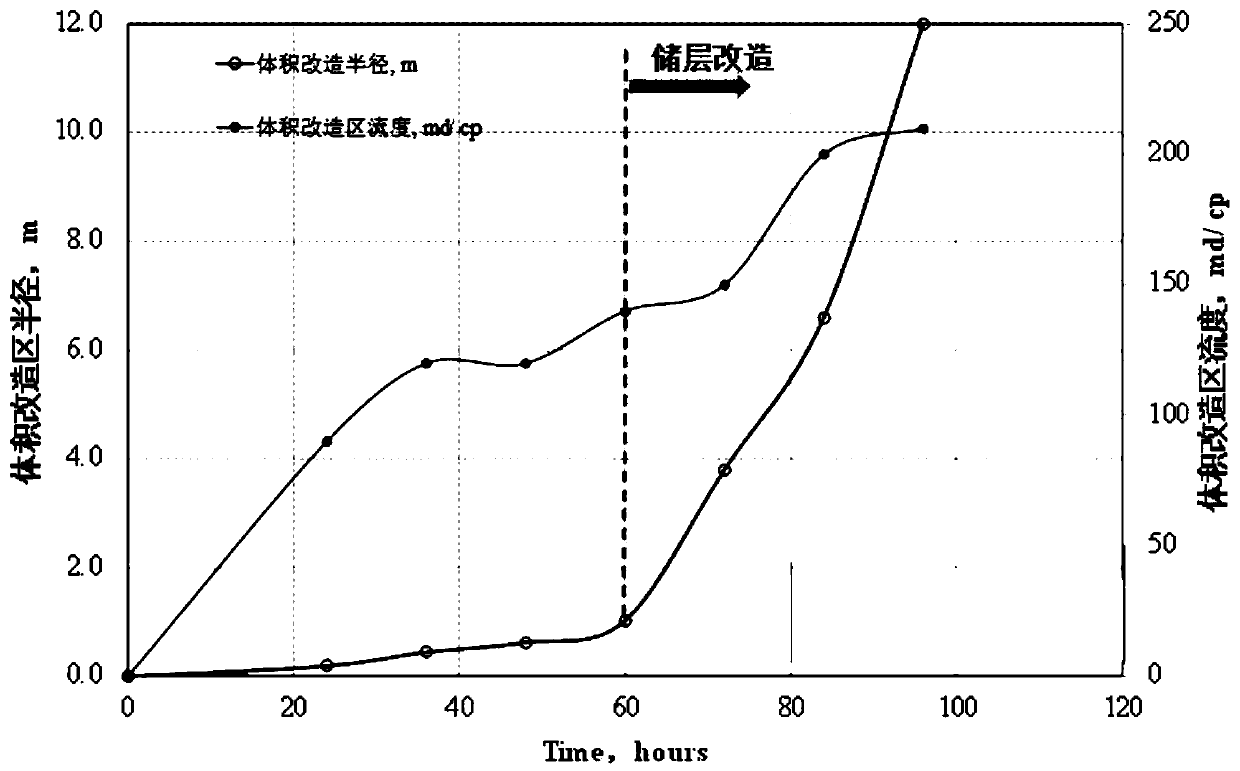

[0037] Step S1. Combined with the analysis of the current oilfield production status, it is determined that Well X implements in-situ stress expansion reconstruction, and conducts on-site small fracture diagnosis test (F-DFIT). The test diagram is as follows figure 1shown. The geomechanical characteristics of the reservoir, such as the three-dimensional principal stress of the reservoir, permeability, reservoir pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com