A vertical hydrothermal coupling model test device and test method

A model test device and water-heat coupling technology, which is applied in the direction of material thermal development, can solve the problems of inability to accurately quantify the influence of seepage, and the difficulty of uniform water flow through the test box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

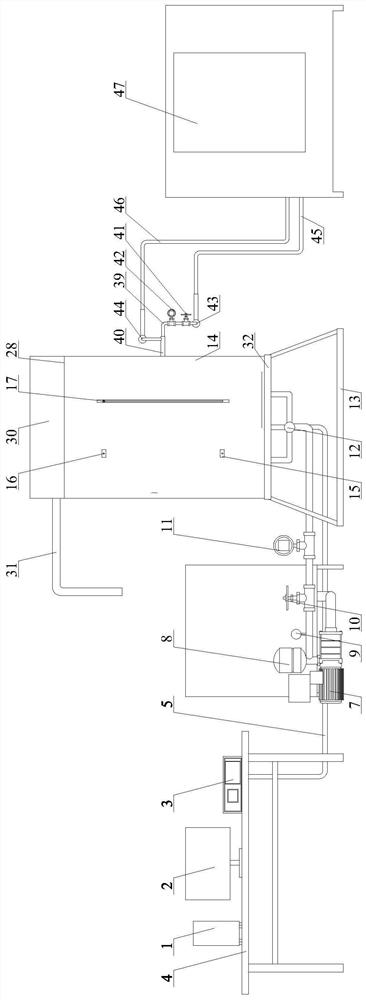

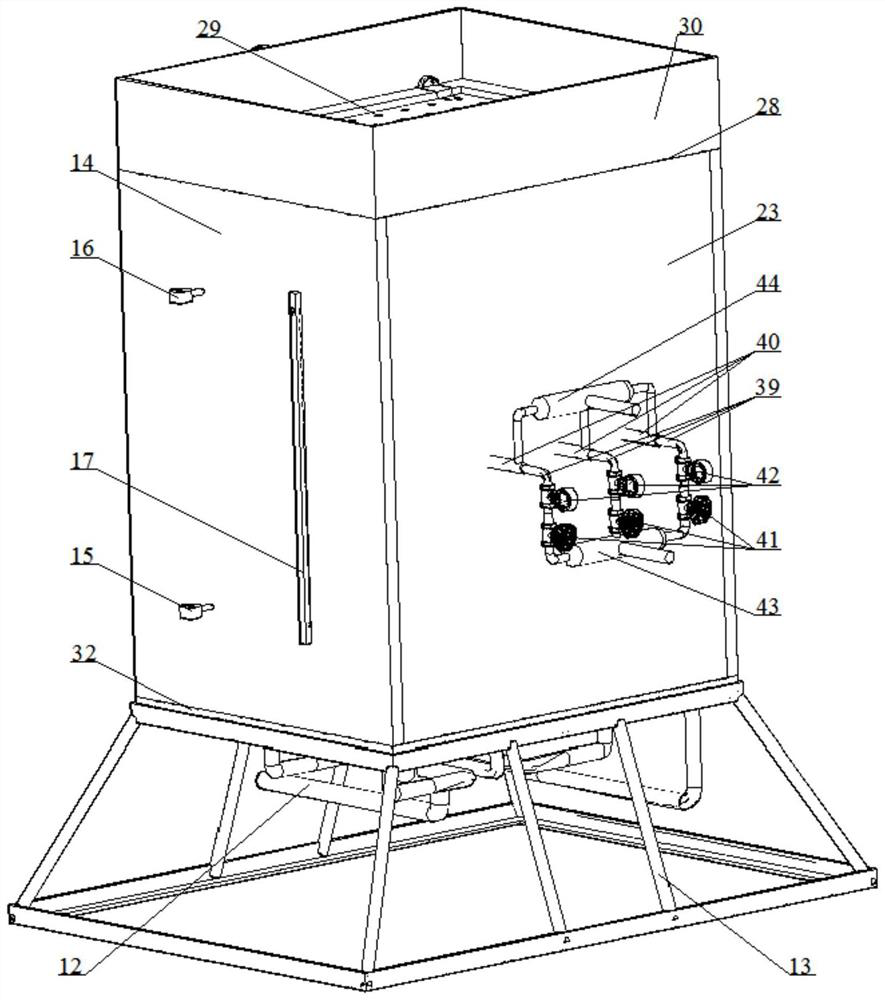

[0099] Such as Figure 1 to Figure 18 As shown, the number of frozen tubes is 3, and the test is carried out according to the geometric similarity criterion, and the selection of C l for 5.

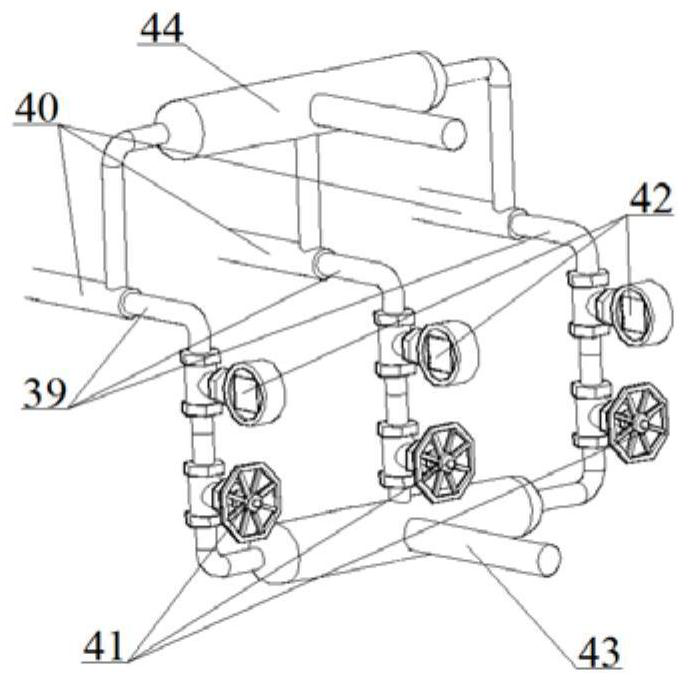

[0100] In the coal mine vertical shaft freezing method construction process, the diameter of the actual freezing pipe is generally 100 mm, and the actual spacing of the freezing pipes is generally 1200 mm. Taking this as the design parameter, the diameter of the freezing inner pipe 39 is 20 mm, and the diameter of the freezing outer pipe 40 is 30 mm. , the spacing of the freezing tubes is 250mm, and the side length of the square mesh of the measuring point layout net 34 is 50mm. 20 thermocouple strings 35 are arranged on the measuring point layout network 34, and each thermocouple string 35 is all vertically arranged, and the 20 thermocouple strings 35 are parallel to each other, and each thermocouple string 35 includes 16 thermocouple strings in the vertical direction. I. The distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com