Heat exchanging structure with corresponding features as well as heat exchanger and application method thereof

A technology of heat exchange structure and corresponding characteristics, applied in the field of new symmetrical heat exchange structure, can solve problems such as application methods that are not involved, and achieve the effects of facilitating large-scale automated production, good economy, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

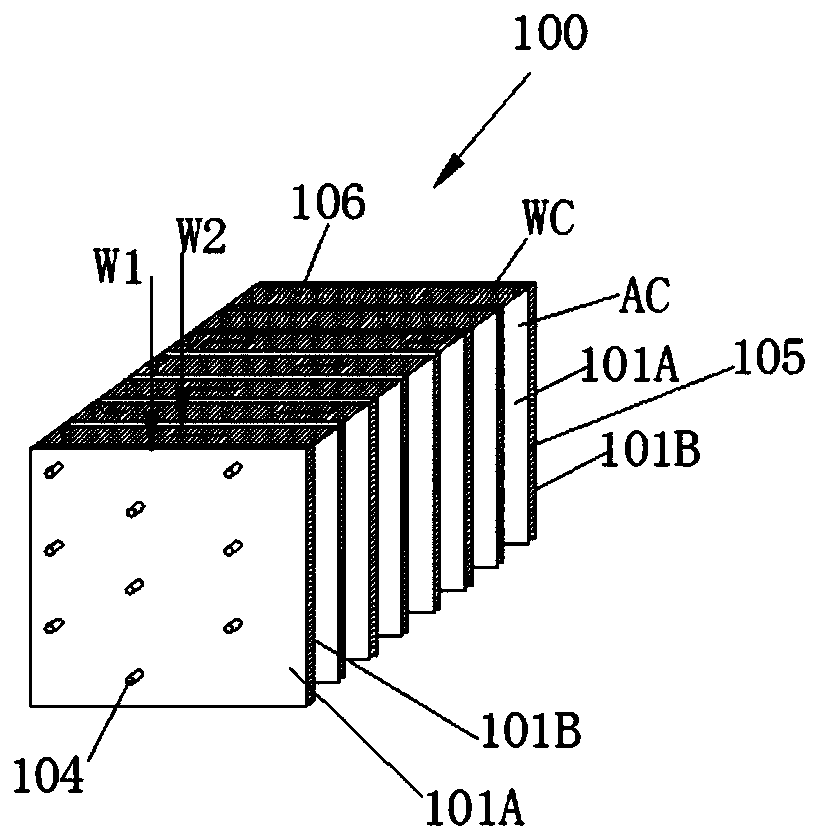

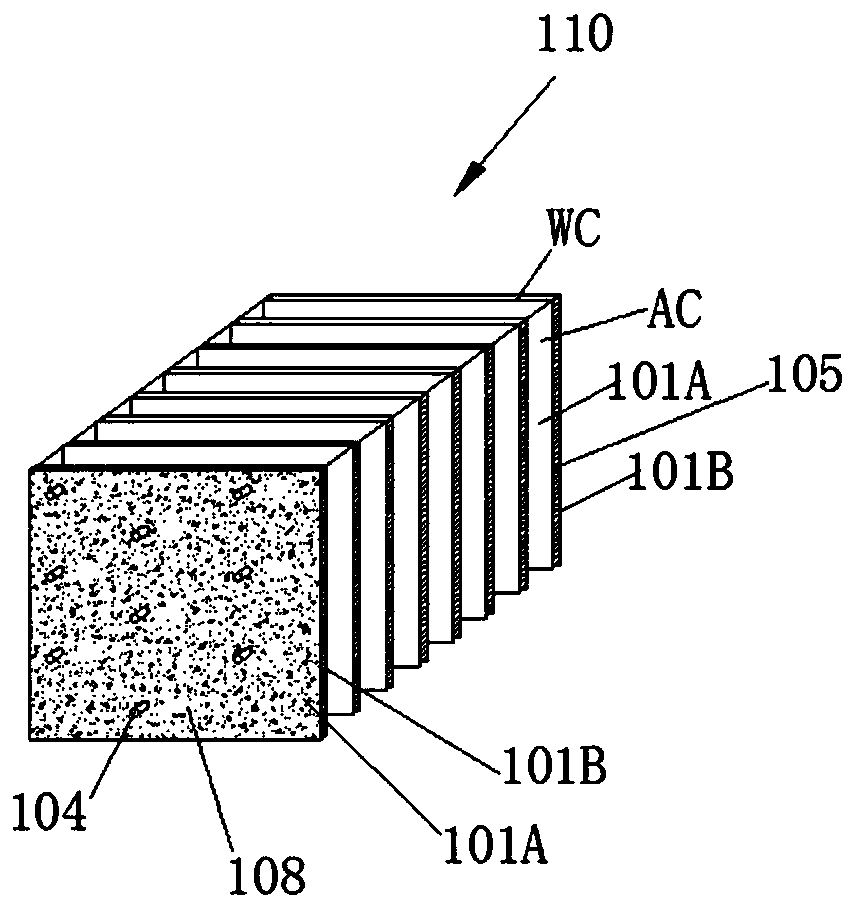

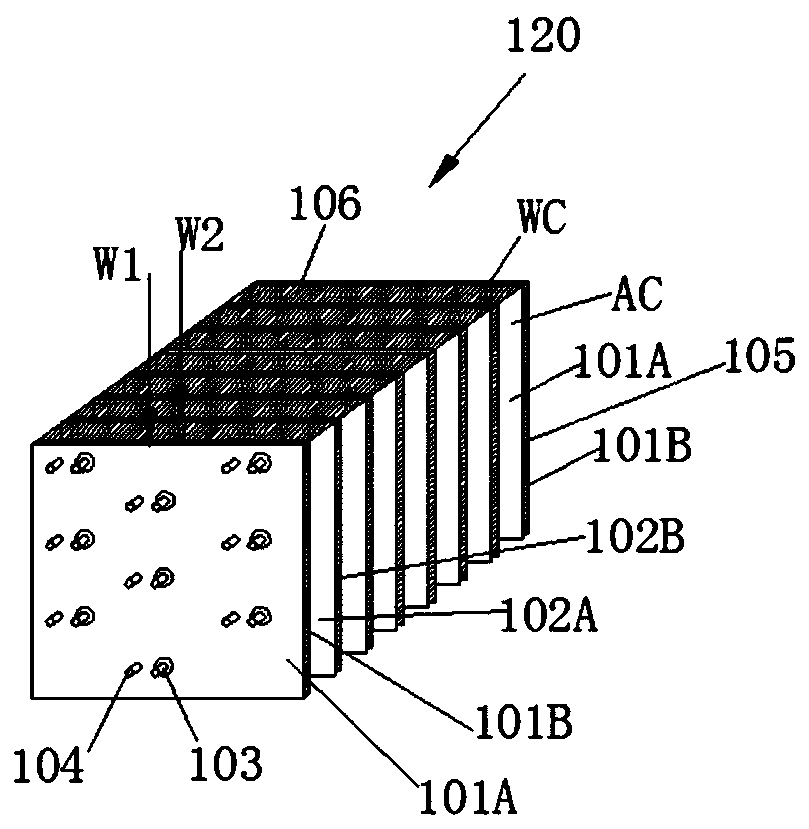

[0093] The invention provides a heat exchange structure with corresponding features, which is composed of a plurality of fins, sealing bodies and structural tubes, the structural tubes pass through the fins and fix the fins, and the fins are sealed around by the sealing body. The sealing body is provided with an air inlet and an air outlet to form passages, and the passages with the same positions of the air inlet and the air outlet are the same group of passages. Functional elements are arranged in the channel, on the channel wall, that is, on the fins, or through the channel, or through the fins, and have at least one of the following corresponding features:

[0094] (1) There are two sets of corresponding heat exchange tubes and fins, the heat exchange tubes run through the fins, and the corresponding heat exchange tubes and fins are fixedly connected.

[0095] (2) There are corresponding two sets of channels, and the two sets of channels are respectively used as auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com