Structural specification sawn timber grading method

A technology for structural and sawn timber, which is applied in the fields of engineering wood products and green prefabricated building materials, can solve problems such as difficult to meet the requirements of use, insufficient industrialization, expensive equipment, etc., and achieve simple and clear analysis process, good effect and low equipment investment. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The invention discloses a method for grading sawn timber with specifications for structures. Taking the imported dried hem-fir (Hem-fir) structure with 2x6 inches (140x38mm) for offline grading as an example, the method includes the following steps:

[0020] S1. The length of dry hemlock-fir is 18 feet (5.4m), and the total number is 4500. Randomly select 50 hemlock-fir sawn timber samples. The number of samples randomly sampled is determined according to the allowable error and confidence level of the relevant mechanical performance indicators.

[0021] S2. Label, weigh and measure the moisture content of the above-mentioned 50 hemlock-fir specification sawn timber samples in sequence, and make records.

[0022] S3. After testing, the moisture content of the sample is between 8.5-15.3%, and the density distribution range is 310-560kg / m 3 . The selected standard lumber samples are cut from both ends according to the relevant standards to process the test pieces for t...

Embodiment 2

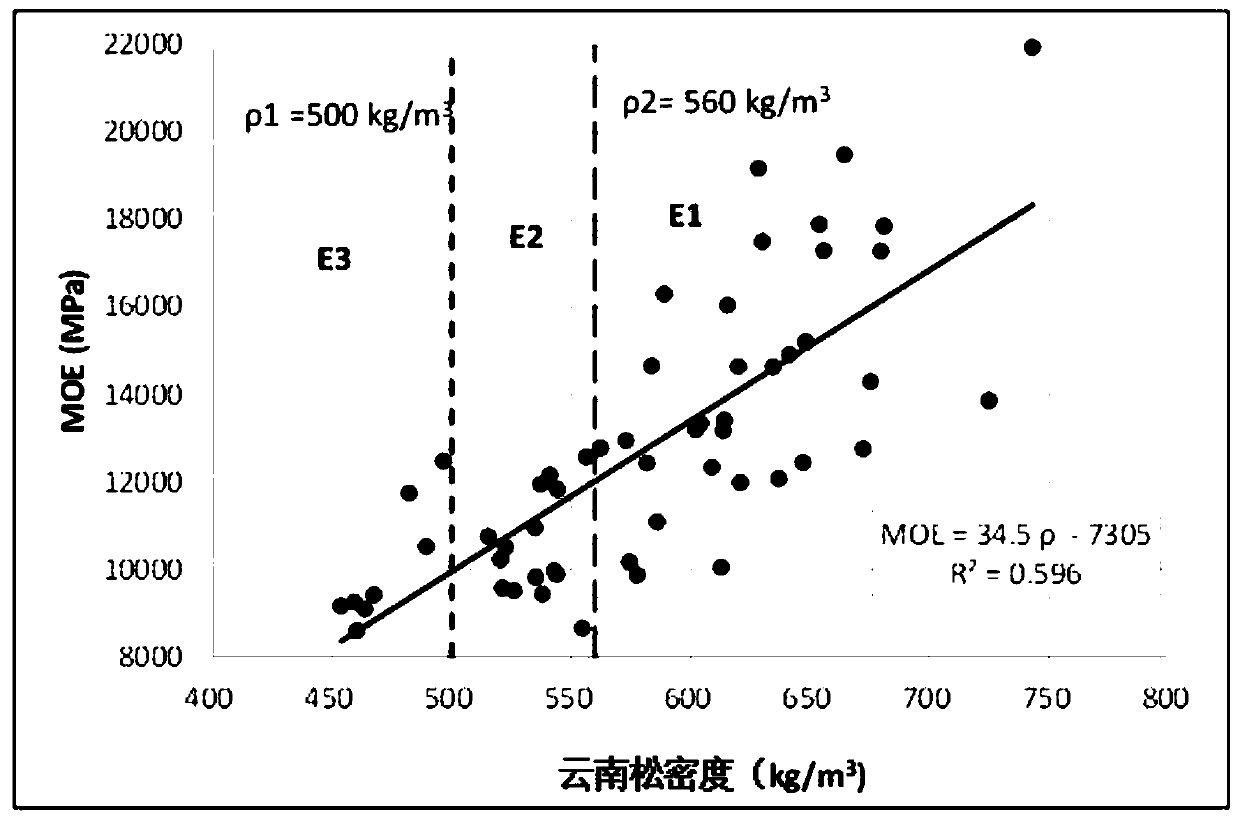

[0026] The invention discloses a method for grading sawn timber with specifications for structural use. Taking domestic dried Yunnan pine 140x40mm specification sawn timber as an example, the method comprises the following steps:

[0027] S1. The length of dried Yunnan pine is 8 feet (2.4m). Randomly select 56 samples of Yunnan pine sawn timber. The number of samples randomly sampled is determined according to the allowable error and confidence level of the relevant mechanical performance indicators.

[0028] S2. Label, weigh and measure the moisture content of the above 56 Yunnan pine sawn timber samples in sequence, and make records.

[0029] S3. After testing, the water content of the sample is between 8.5-15.3%, and the density distribution range is 450-585kg / m 3 . Then cut the selected standard lumber samples from both ends according to the relevant standards to process the test pieces for the bending test, and take 2 test pieces for each standard lumber sample, a tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com