Natural gas leakage monitoring system and monitoring method

A monitoring system, a technology for natural gas, applied in the direction of detecting the appearance of fluid at the leak point, measuring device, color/spectral characteristic measurement, etc., can solve the problems of small monitoring area, large loopholes, large maintenance, etc. The effect of low difficulty, high wavelength selectivity, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

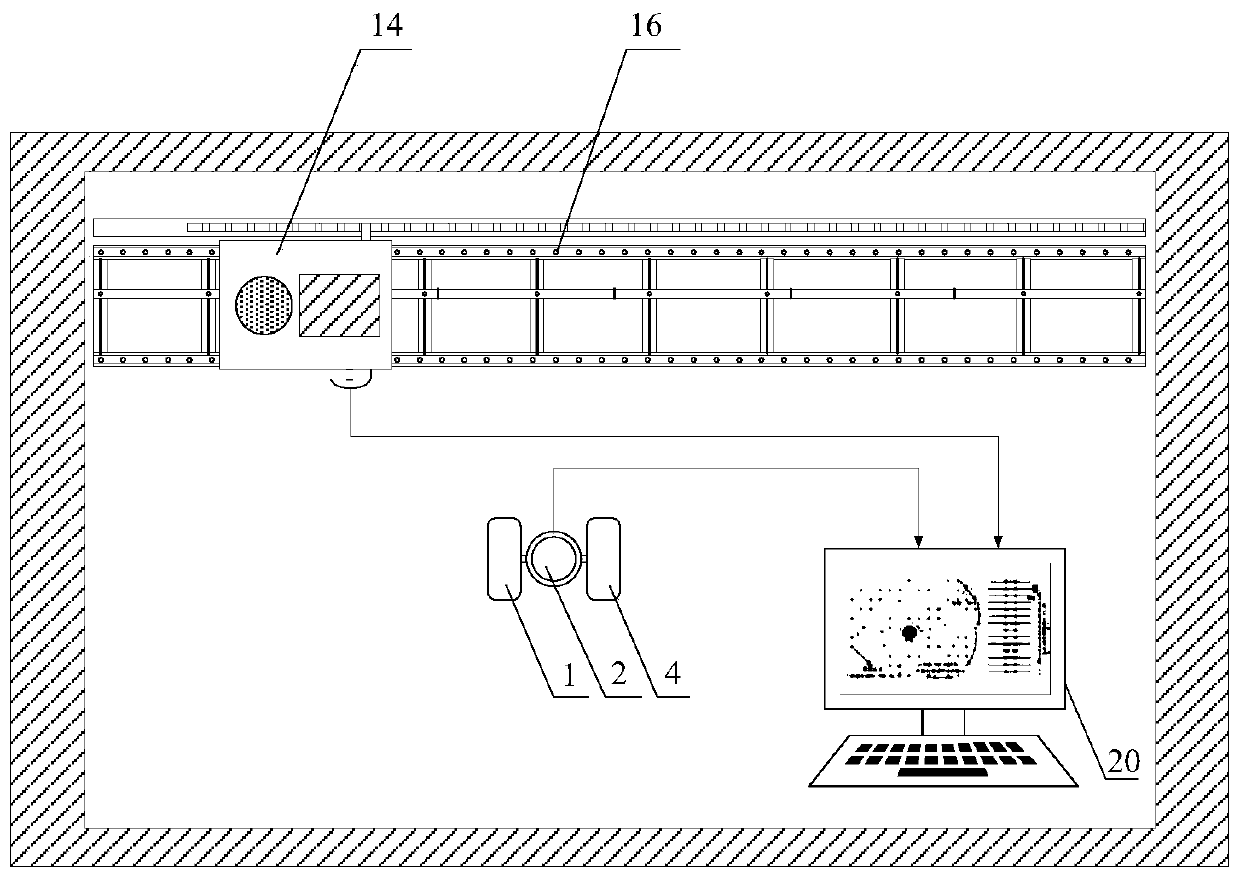

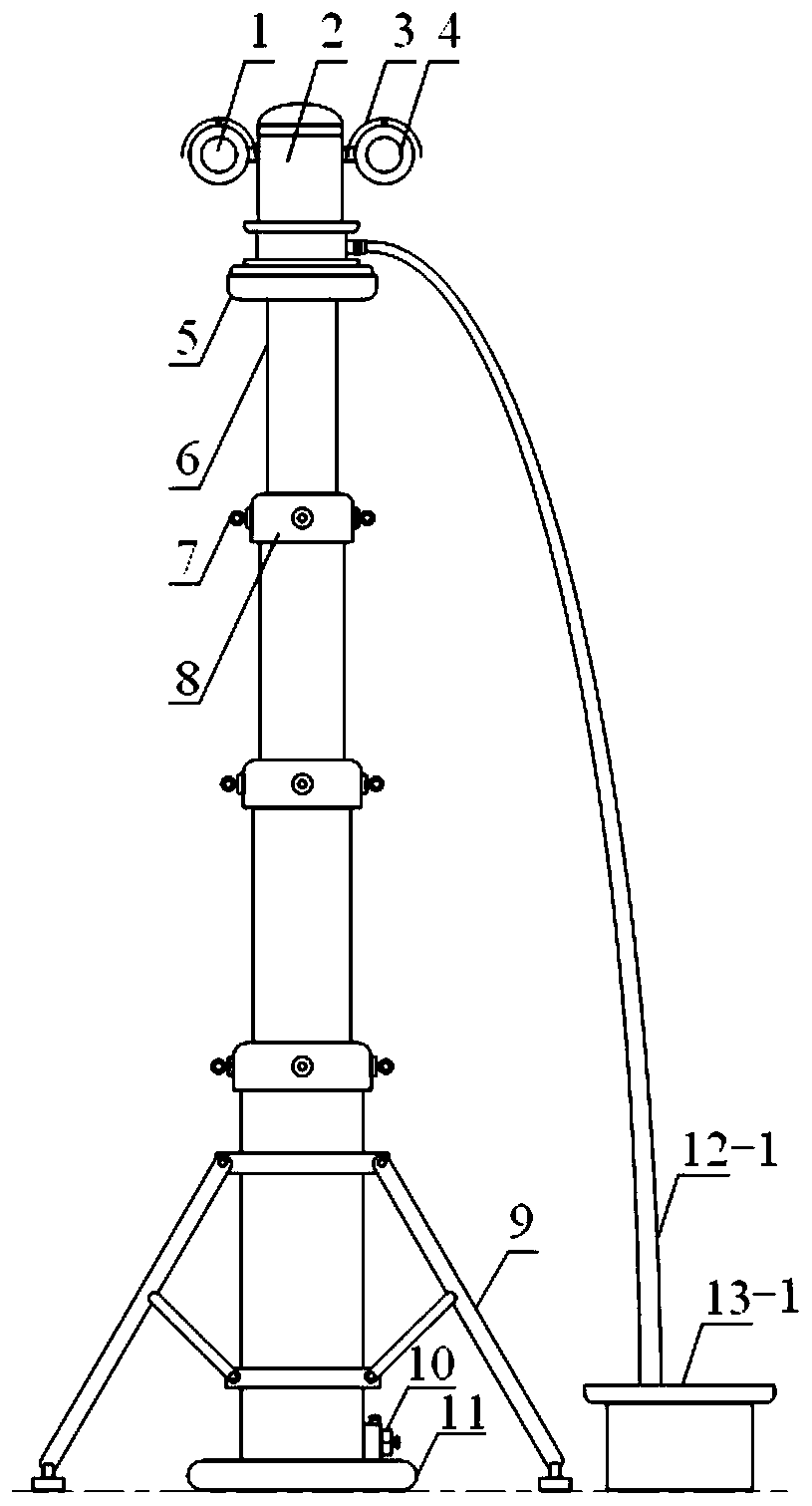

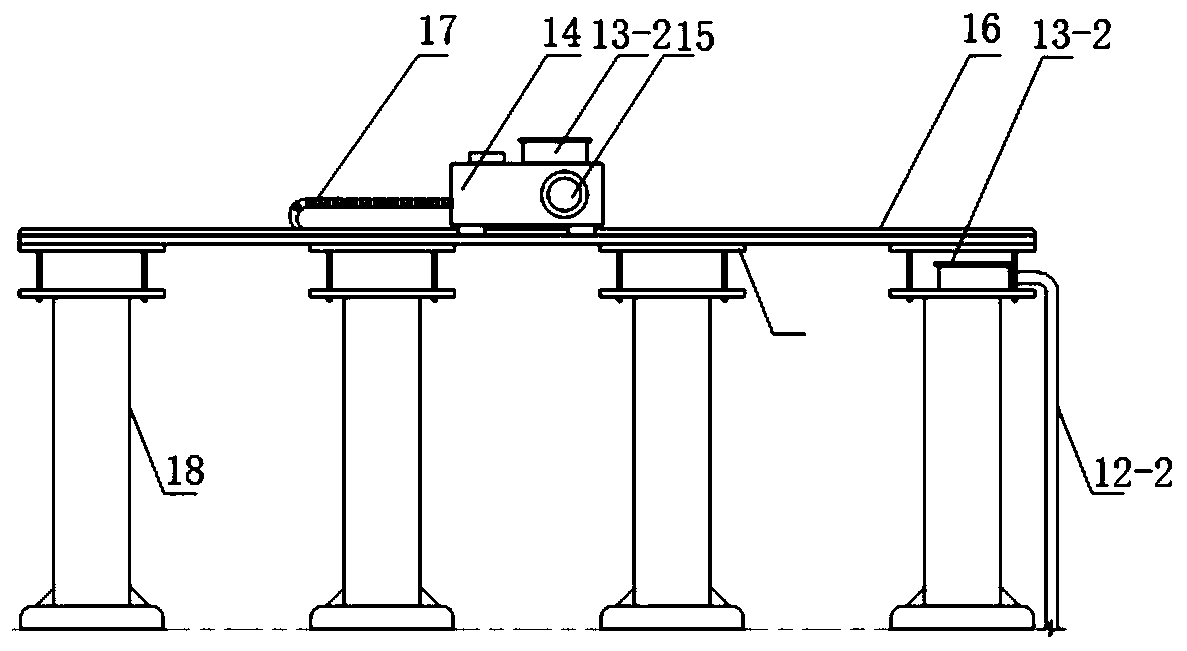

[0031] Such as Figure 1-3 As shown, the natural gas leakage monitoring system of this embodiment includes a laser gas remote measurement device, a lifting pole, a laser gas remote measurement instrument 15 , a guide rail 16 and a server terminal 20 .

[0032] Among them, the laser gas remote measurement device is a scanning remote sensing monitoring instrument, and the laser gas remote measuring instrument is an open remote sensing monitoring instrument, both of which adopt the advanced TDLAS measurement principle, which can realize remote sensing measurement of gas concentration under an open optical path.

[0033] The lift-type vertical pole is installed at a suitable target position in the process area of the natural gas station, and the laser gas remote measurement device is installed on the top of the lift-type vertical pole. The laser gas remote measurement device cruises according to the preset position to realize "line monitoring".

[0034] The guide rail 16 is arra...

Embodiment 2

[0050] The natural gas leakage monitoring system of this embodiment differs from Embodiment 1 in that:

[0051] Omit the setting of the server terminal and its communication connection, and adopt the monitoring scheme of the scanning laser gas remote measuring device and the open laser gas remote measuring instrument respectively by adopting the lifting pole and the guide rail, the number of monitoring equipment is small, and the difficulty of data processing is small. It can realize the measurement of the leakage point of the whole natural gas station.

[0052] For other system architectures, reference may be made to Embodiment 1.

Embodiment 3

[0054] The natural gas leakage monitoring system of this embodiment differs from Embodiment 1 in that:

[0055] Through the laser gas remote measurement device and the laser gas remote measurement instrument, the detection signal is directly transmitted wirelessly to the server terminal, omitting the setting of the explosion-proof control box and its related components, and simplifying the system structure.

[0056] For other system architectures and monitoring methods, reference may be made to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com