Method for reducing noise of film capacitor

A film capacitor, noise technology, applied in the direction of film/thick film capacitors, feedthrough capacitors, laminated capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

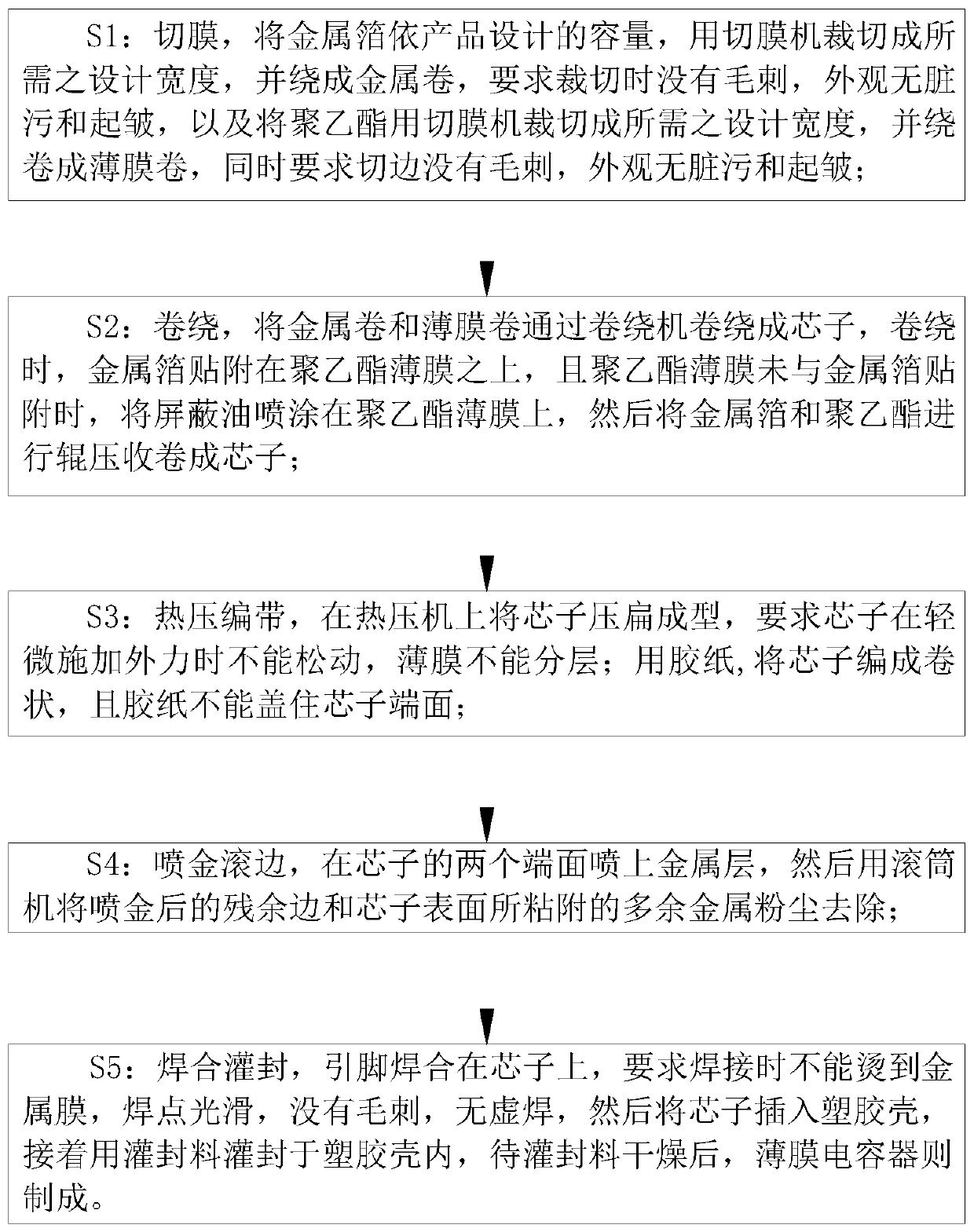

Method used

Image

Examples

Embodiment approach

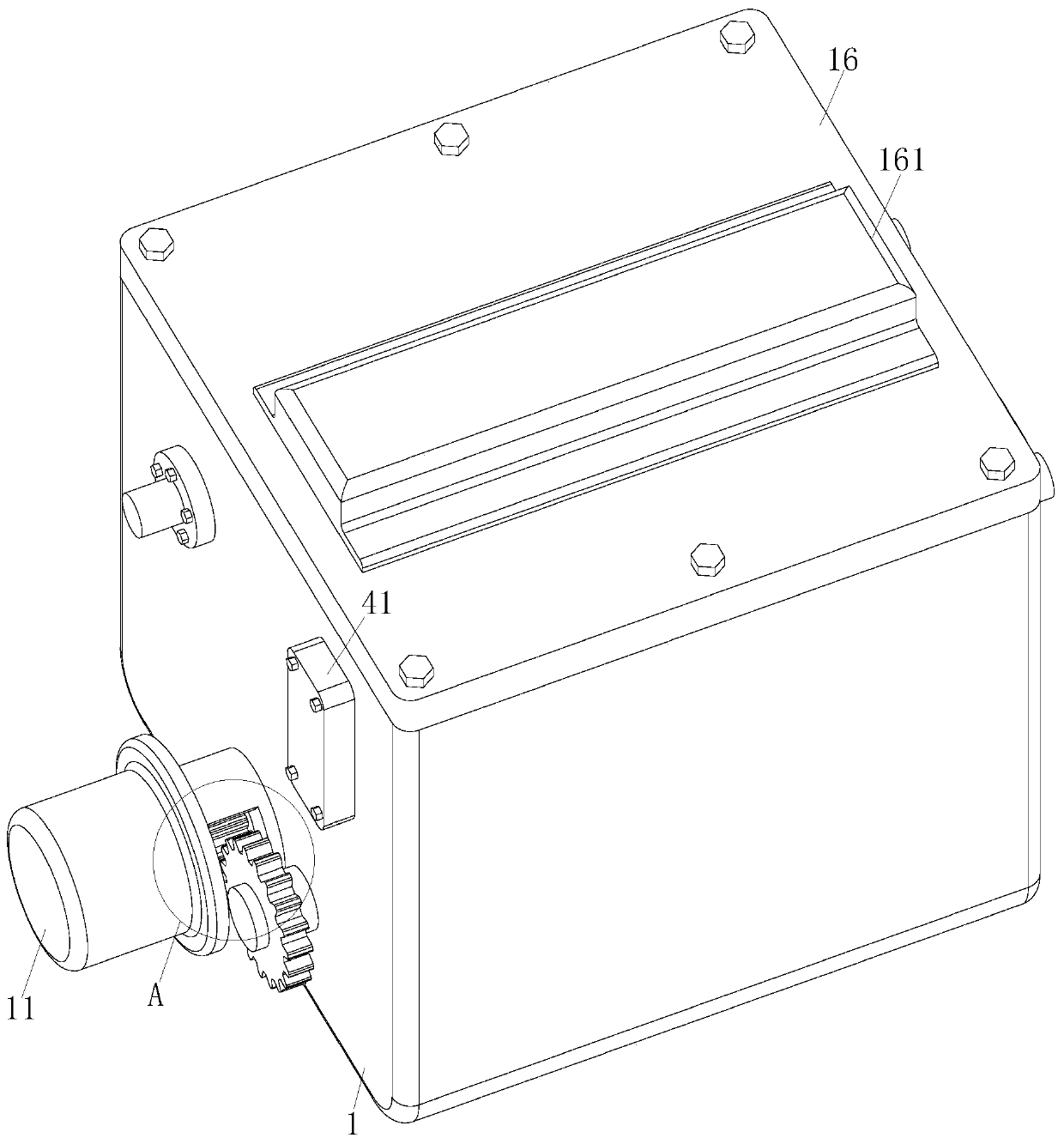

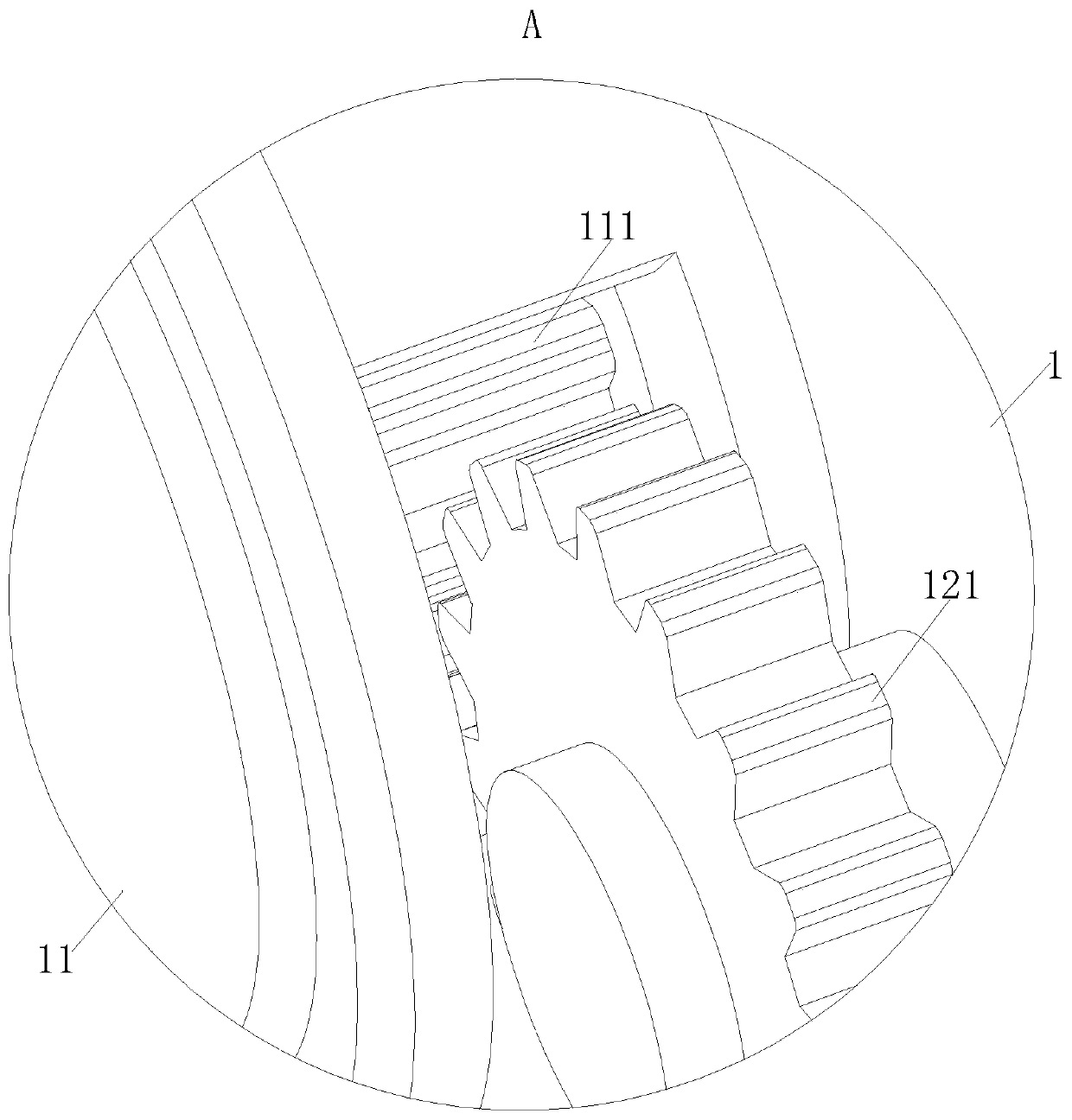

[0039] As an embodiment of the present invention, a pressing unit 2 is provided on one side of the winding roller 12; the pressing unit 2 includes a sliding block 21, an arc washer 22 and a roller 23; the lower end of the sliding block 21 is embedded in In the sliding groove 17 opened at the bottom of the housing 1, and the sliding block 21 is connected in the sliding groove 17 through the No. 1 spring 211, and the arc-shaped washer 22 is fixed on the side wall of the sliding block 21 close to the winding roller 12; The raised part on the washer 22 is hinged to the roller 23; through the pressing unit 2, the metal foil and polyethylene film rolled up on the take-up roller 12 are further pressed tightly; After the ethyl ester film is rolled, the No. 1 spring 211 squeezes the sliding block 21, and then the sliding block 21 squeezes the arc washer 22, and at the same time the roller 23 of the arc washer 22 presses the metal foil wound on the outer ring of the winding roller 12 An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com