Lithium-sulfur battery electrolyte, application thereof and lithium-sulfur battery

A lithium-sulfur battery and electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as unsatisfactory effects, achieve good synergistic effects, improve conversion efficiency, and reduce deposition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Lithium-sulfur batteries were prepared as follows:

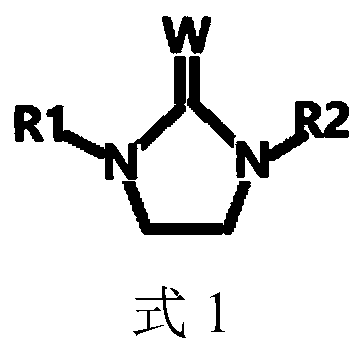

[0044] ①Electrolyte configuration: in a glove box with argon atmosphere (H 2 O3 ~R 4 is methyl), fully stirred evenly, promptly obtains the lithium-sulfur battery electrolyte of the present invention.

[0045] ②Preparation of sulfur positive electrode: mix sulfur / carbon composite material (70% sulfur load), acetylene black, and PVDF at a ratio of 90:3:7, and then add an appropriate volume of N-methylpyrrolidone (NMP) Stir in a slurry machine for 15 minutes at a speed of 15 kr / min to form a stable and uniform positive electrode slurry. The slurry was coated on a carbon-coated aluminum foil with a doctor blade, and dried in an oven at 80°C for 8 hours until the NMP was completely volatilized.

[0046] ③Lithium-sulfur button battery assembly test: The prepared sulfur pole piece was punched into a Φ13mm circular pole piece, and baked in an oven at 55°C for 1h. In an argon atmosphere, a lithium metal sheet was used as ...

Embodiment 2-15 and comparative example 1

[0048] Compared with Example 1, the only difference lies in the added components of the electrolyte (the types and contents of auxiliary additives and additives are different, see Table 1 for details), and other parameters and preparation methods are the same as in Example 1.

[0049] Part of the experimental conditions of table 1 embodiment 2-15 and comparative example 1

[0050]

[0051]

[0052] The test results of each embodiment of table 2 and comparative example 1

[0053]

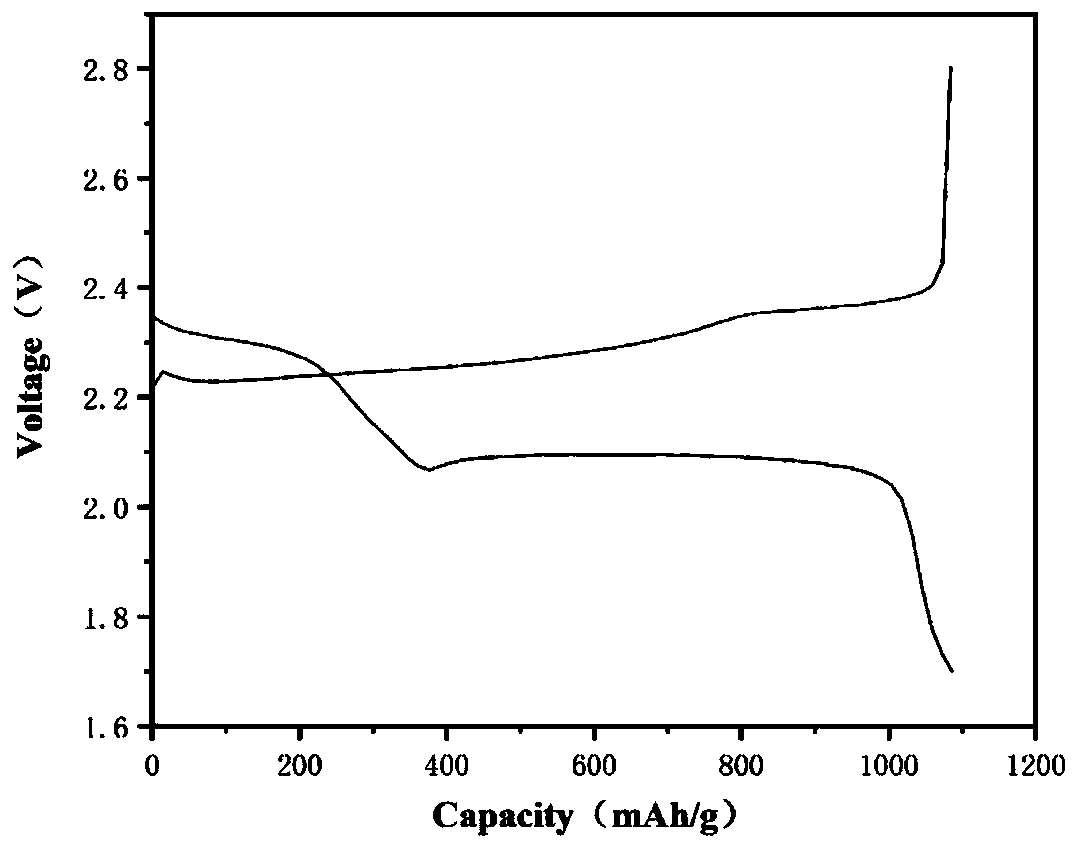

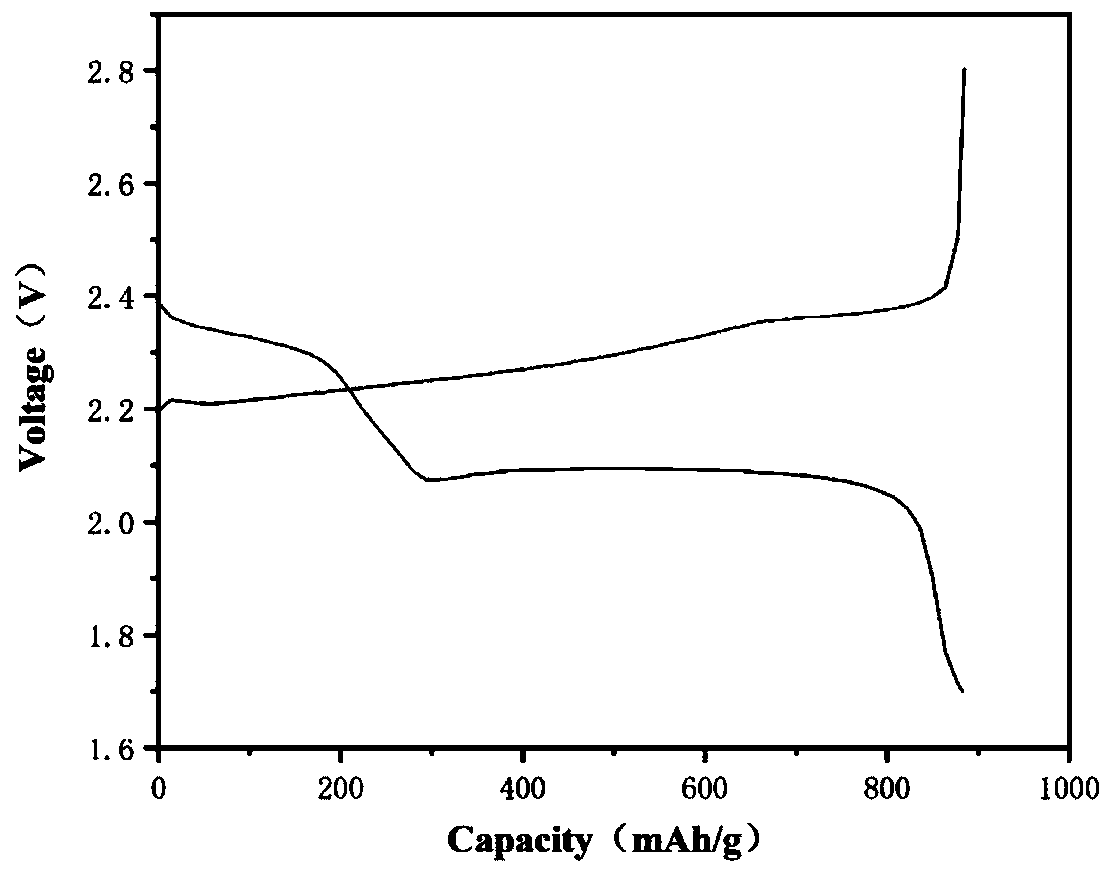

[0054] Compared with Comparative Example 1 in Examples 1 to 6, the specific discharge capacity of the first cycle in Comparative Example 1 is 886mAh / g at a discharge rate of 0.5C, and the specific discharge capacity of the first cycle in Examples 1 to 6 increases compared with it 138-328mAh / g, the 100-cycle cycle performance also increased from 47.74% to 69.58-74.95%, and the Coulombic efficiency increased from 98.1% to the best 99%. It can be seen that adding the additive of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap