Pastry batch forming equipment

A molding equipment and pastry technology, which is applied in the field of pastry batch forming equipment, can solve the problems of difficult baking operations of different shapes of pastries and the inability to meet the diverse production needs of pastries, and achieve the effects of facilitating packaging operations, improving processing efficiency, and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

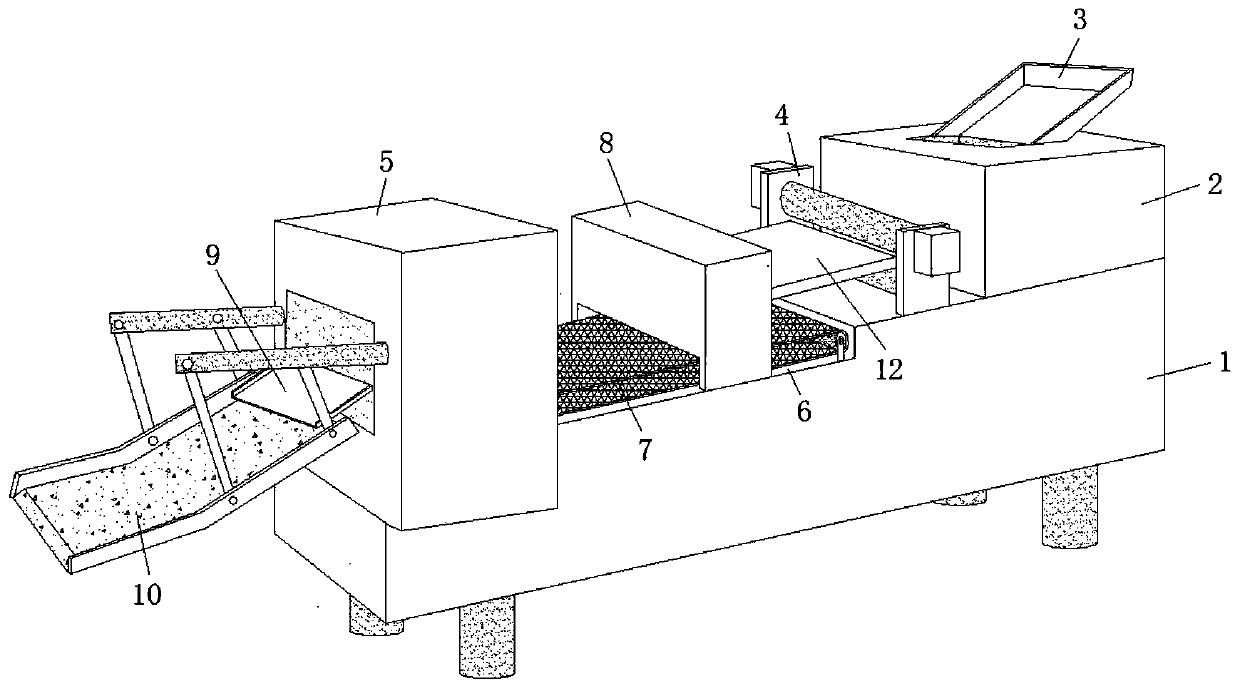

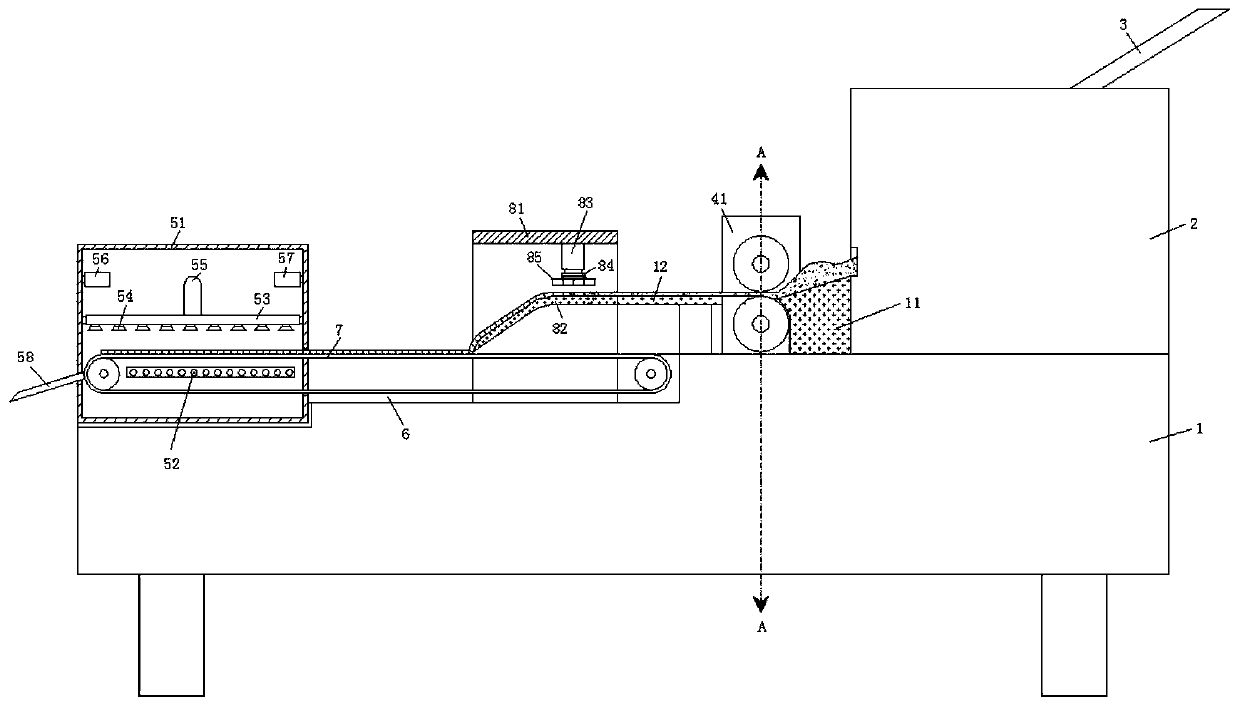

[0029] refer to Figure 1-5 , a batch molding equipment for cakes, comprising a workbench 1, a flour mixer 2 is fixedly connected to one side of the top surface of the workbench 1, and a feeding tray 3 is fixedly connected to the side of the input end of the flour mixer 2 away from the center of the workbench 1, One side of the flour mixer 2 is provided with a pastry primary forming mechanism 4, and the other side of the workbench 1 is also provided with a baking mechanism 5. The baking mechanism 5 includes a baking oven 51, and the inner walls of the front and rear sides of the lower end of the baking oven 51 are fixed with The heating plate 52, the inner wall on both sides of the upper end of the baking oven 51 are fixedly connected with a suction dish 53, the lower end of the suction dish 53 is connected with a suction funnel 54, and the middle part of the top surface of the suction dish 53 is connected with an exhaust pipe 55. A temperature sensor 56 and a humidity sensor ...

Embodiment 2

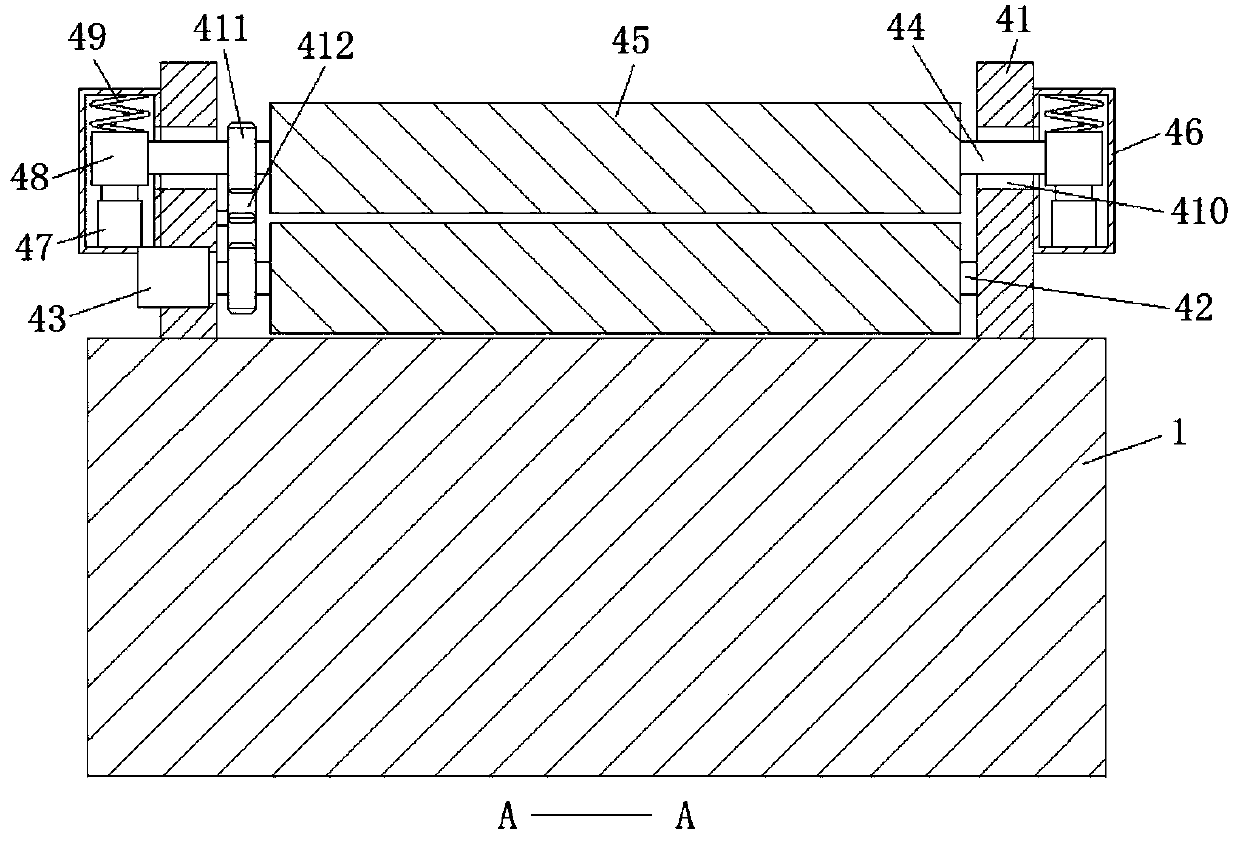

[0032] Such as figure 2 and 3 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, the initial cake forming mechanism 4 includes a support base 41, and the lower ends of the two support bases 41 are rotatably connected with an extruding rod-42 through rolling bearings, and the rear end of the extruding rod-42 end is provided with servo motor 43, and the output end of servo motor 43 and extruding rod one 42 are fixedly connected by screw, and the upper side of extruding rod one 42 is provided with extruding rod two 44, extruding rod two 44 and extruding rod two The outer walls of one 42 are all fixedly connected with pressure rollers 45 by screws, and the upper ends of the two supporting seats 41 facing away from each other are fixedly connected with mounting pans 46, and the inner bottom surfaces of the mounting pans 46 are all fixedly connected with electric telescopic rods 2 47, which are electrically telescopic. The output ends of the rod tw...

Embodiment 3

[0036] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, one end of the transmission chain plate 7 extends to the inside of the oven 51, and the chain plates of the transmission chain plate 7 are arranged in a net shape, and the heating plate 52 is located at the upper and lower ends of the chain. Between the plates, a plurality of suction funnels 54 are provided and evenly distributed on the lower end of the suction dish 53 .

[0037] In this embodiment, a plurality of suction funnels 54 are arranged directly above the heating plate 52, so as to facilitate the rapid discharge of the hot air generated during baking of the pastry, thereby ensuring the efficiency of pastry baking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com