Method and device for purifying air and removing fine particles

A technology for purifying air and fine particles. It is applied in chemical instruments and methods, separation methods, and filtration of dispersed particles. It can solve the problems of inability to adsorb toxic gases, low efficiency, and easy generation of ozone, and reduce labor intensity and production maintenance. cost, meet the process requirements of production continuity, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

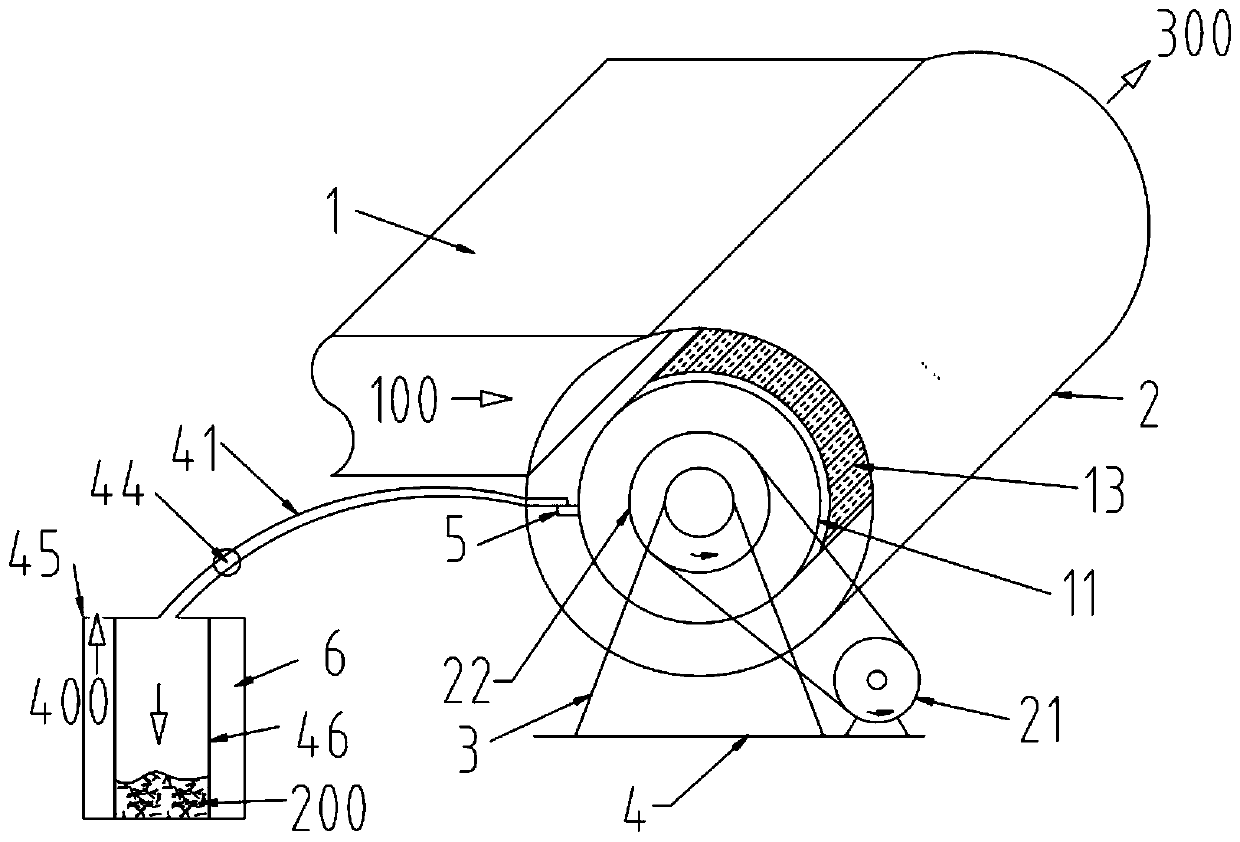

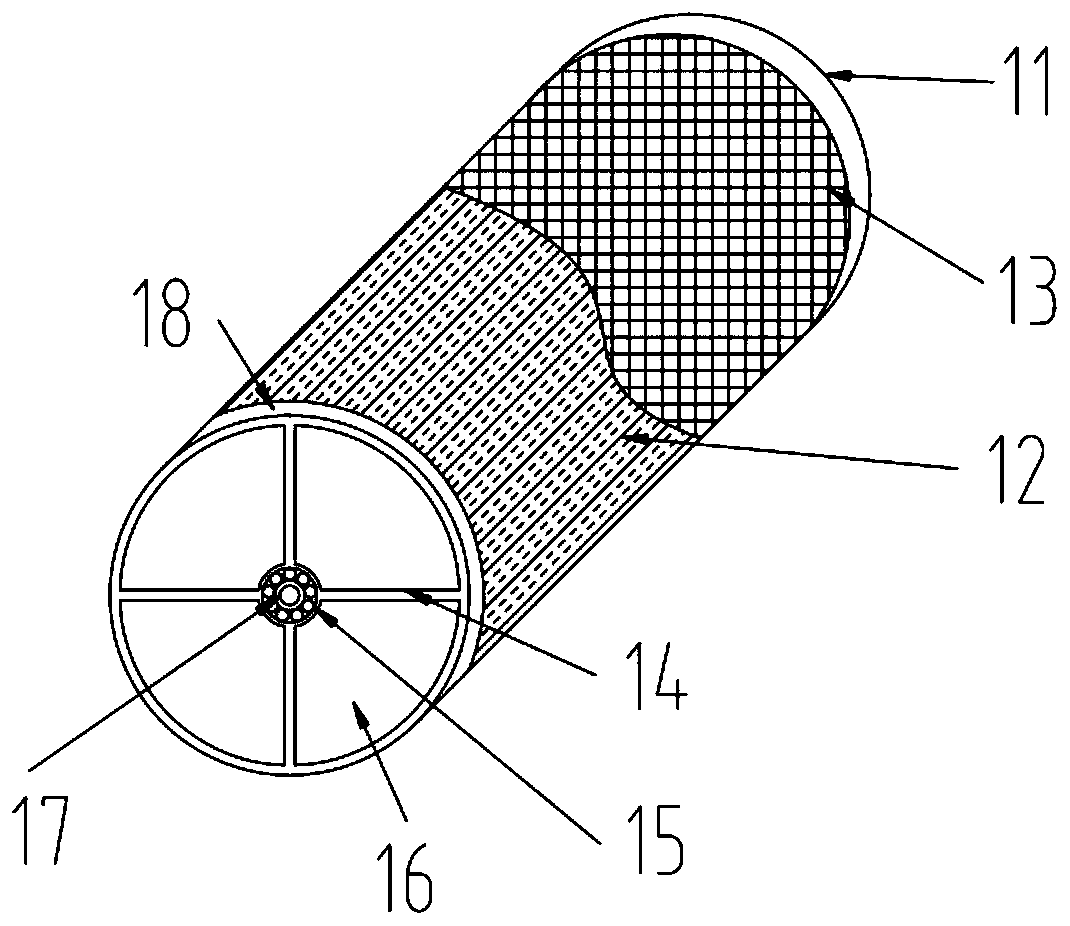

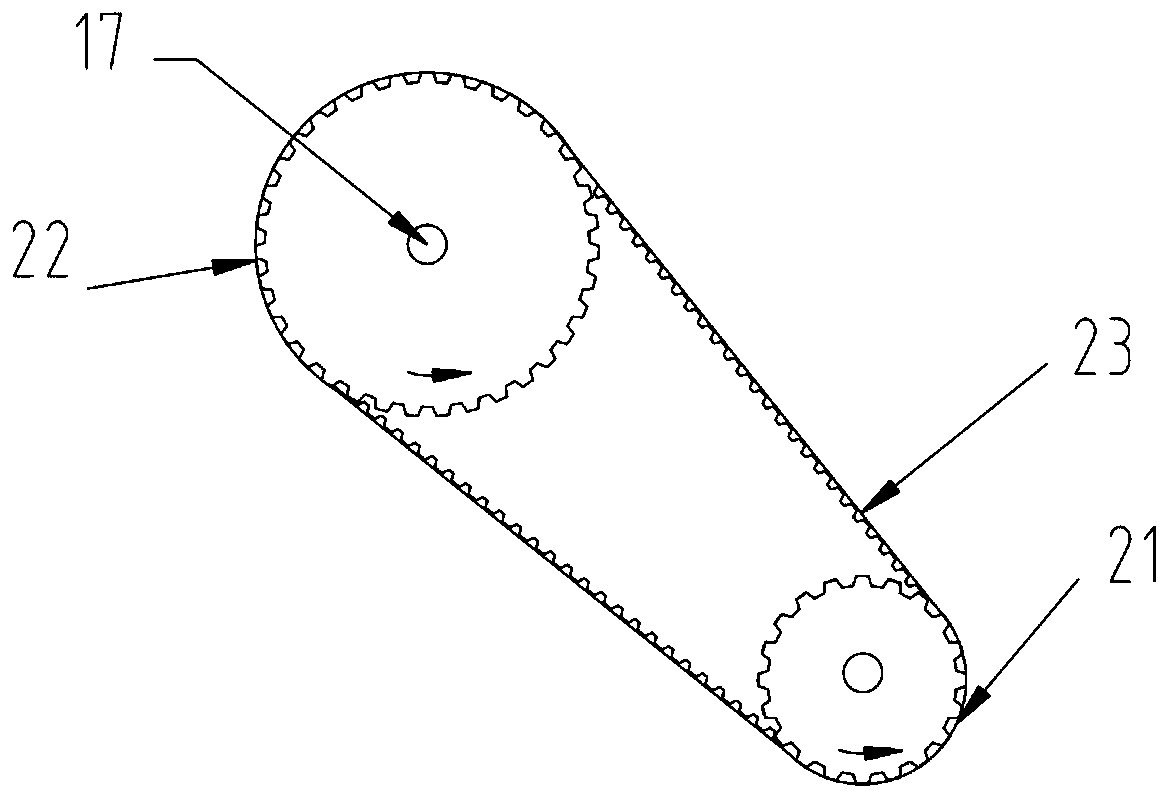

[0053] This embodiment provides a method for purifying air and removing fine particles, such as Figure 9 As shown: the air to be cleaned in the rectangular purified air introduction pipe (1) enters the cylindrical shell (2) supported by the outrigger (3) and the base plate (4) at a wind speed of 10 m / s, and is then driven by a small synchronous wheel (21) After the filter membrane (12) on the outer surface of the filter cartridge (11) that drives the large synchronous wheel (22) to rotate at a speed of 0.5m / s is filtered, the filtered and purified air (300) is passed through the filter cartridge (11) The flow out of the end face enters the purification air conditioner, and after temperature and humidity adjustment, it flows back to the purification workshop. The fine particles (200) adhered to the filter membrane (12) are sucked out by the brush (5) and the negative pressure pump (44) in the dust collection mechanism (6), and enter the storage tank (45), and the fine particle...

Embodiment 21

[0076] This embodiment provides a device for purifying air and removing fine particles. The difference from Embodiment 1 is that the diameter of the filter cartridge is 1.5 meters.

[0077] In this embodiment, the treatment capacity of the air to be purified is 10000 m³ / min.

Embodiment 22

[0079] This embodiment provides a device for purifying air and removing fine particles. The difference from Embodiment 1 is that the diameter of the filter cartridge is 2 meters.

[0080] In this embodiment, the treatment capacity of the air to be purified is 30,000 m³ / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com