Gas distribution plate for vibrated fluidized bed

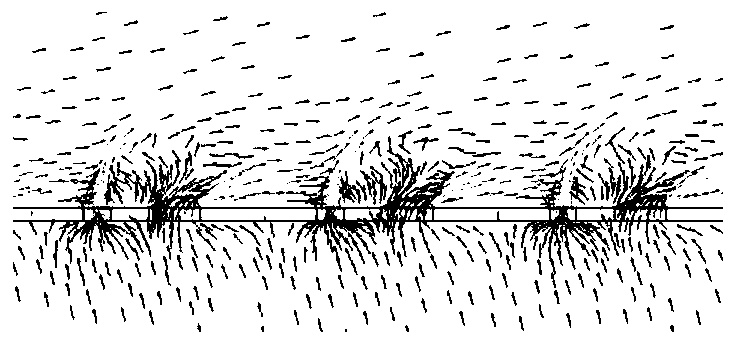

A gas distribution plate, plate body technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of large collision probability between particles and cone caps, no guiding function, large resistance loss, etc., to prevent dead beds. generation, good fluidization conditions, enhanced disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

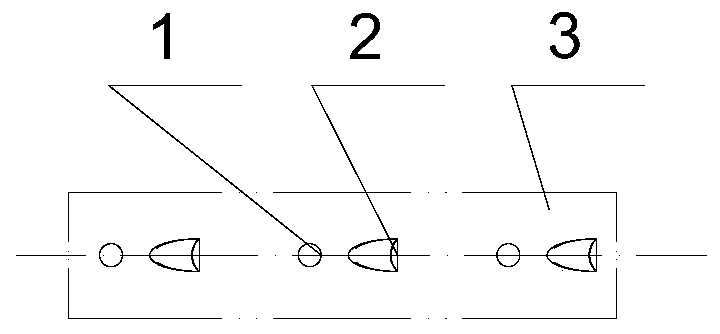

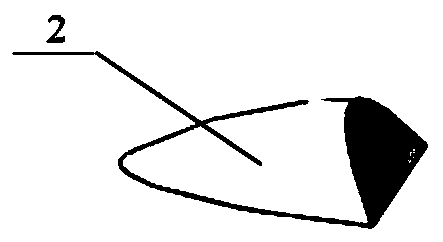

[0048] Figure 8 An arrangement of gas distribution holes is given. Straight holes 1 are arranged in an equilateral triangle with side length L 3 =L 4 =20mm, α=60°, a straight hole 1 is arranged on the opposite side of the opening direction of each ellipsoidal curved surface guide hole 2 with a chamfered angle, and the exit of the ellipsoidal curved surface guide hole 2 with a chamfered angle is to the opposite side of the opening direction The center distance L of the set straight hole 1 2 is 15.5mm. Ellipsoidal surface guide hole with chamfer 2 long L 1 , width B 1 , high H 1 They are 8mm, 5.5mm, and 2mm respectively, and the cutting angle θ is 120°. The matching straight hole 1 has a diameter of 4mm, and the diameter of the straight hole is 0.73 times the width of the guide hole on the ellipsoidal surface with chamfered corners. The plate body 3 has a thickness of 2 mm. use Figure 8 The structure of the gas distribution plate is shown, and the size of the distrib...

Embodiment 2

[0050] Figure 9 A gas distribution plate arrangement is given. The straight holes 1 are arranged in a rectangle, and the distance between the centers of two adjacent straight holes is L 5 =35mm, distance L between two adjacent rows of straight holes 6 = 20mm. A straight hole 1 is arranged on the opposite side of the opening direction of each ellipsoidal curved surface guide hole 2 with a chamfered angle, and the center distance from the exit of the ellipsoidal curved surface guide hole 2 with a chamfered angle to the straight hole 1 set on the opposite side of the opening direction L 2 is 15.5mm. Ellipsoidal surface guide hole with chamfer 2 long L 1 , width B 1 , high H 1 They are 8mm, 5.5mm, and 2.04mm respectively, and the cutting angle θ is 90°. The matching straight hole 1 has a diameter of 5.5mm, and the diameter of the straight hole is 1 time of the width of the guide hole on the ellipsoidal surface with chamfered corners. The plate body 3 has a thickness of 2...

Embodiment 3

[0052] Figure 10 A gas distribution plate arrangement method is given, the straight holes 1 are arranged in a square, and the distance between the centers of two adjacent straight holes is L 5 =35mm, distance L between two adjacent rows of straight holes 6 = 35mm. A straight hole 1 is arranged on the opposite side of the opening direction of each ellipsoidal curved surface guide hole 2 with a chamfered angle, and the center distance from the exit of the ellipsoidal curved surface guide hole 2 with a chamfered angle to the straight hole 1 set on the opposite side of the opening direction L 2 is 15.5mm. Ellipsoidal surface guide hole with chamfer 2 long L 1 , width B 1 , high H 1 They are 8mm, 5.5mm, and 1.31mm respectively, and the cutting angle θ is 165°. The matching straight hole 1 has a diameter of 7mm, and the diameter of the straight hole is 1.27 times the width of the guide hole on the ellipsoidal surface with chamfered corners. The plate body 3 has a thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com