Device for tablet powder-grinding and mixing, applied to medical care department

A mixing device and tablet technology, applied in the field of medical care, can solve the problems of easy adhesion of drugs, insufficiently uniform and incomplete grinding, and time-consuming manual grinding, and achieve the effects of avoiding mutual infection, facilitating cleaning, and ensuring grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

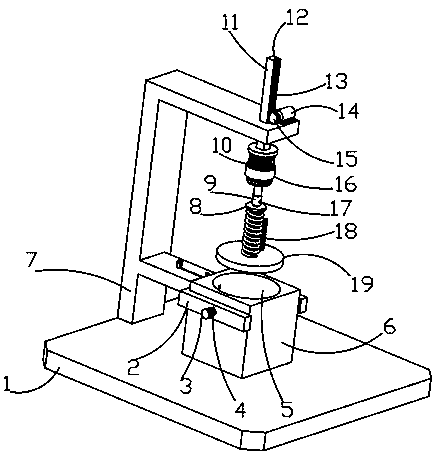

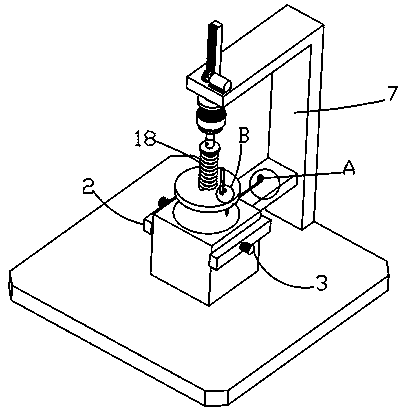

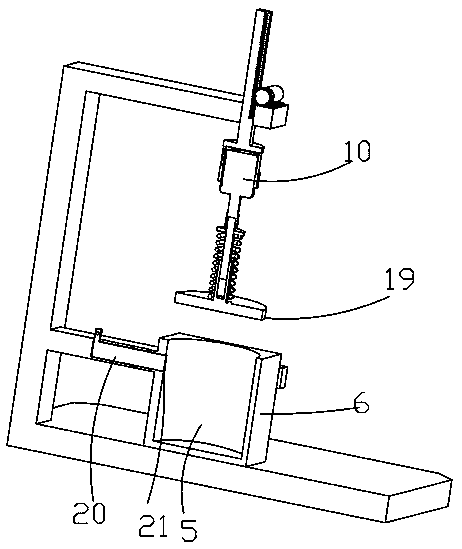

[0033] Such as Figure 1-7A medical tablet grinding and mixing device shown in the medical care department includes a worktable 1, a grinding cylinder 6, a grinding motor 10 and a driving motor 14, the grinding motor 10 and the driving motor 14 are electrically connected to an external power supply, and the top of the working table 1 The left end is fixedly connected with an F-shaped frame 7, the top of the F-shaped frame 7 is fixedly mounted with a drive motor 14, the output end of the drive motor 14 is fixedly connected with a ring gear 15, and the top of the F-shaped frame 7 is fitted and slidably connected with a slide plate 11 through a straight hole. The side wall of the slide plate 11 is provided with a straight groove 12, the side wall of the straight groove 12 is fixedly connected with a gear block 13 used in conjunction with the ring gear 15, the bottom of the slide plate 11 is fixedly connected with a mounting frame 16, and the mounting frame 16 is fixedly connected ...

Embodiment 2

[0035] Such as Figure 1-7 As shown, the drug powder loosening structure includes an inverted T-shaped scraper 22, a bump 31, a third pin 32 and a fourth spring 33, the grinding disc 19 is provided with an inverted T-shaped groove 23, and the inverted T-shaped groove 23 is fitted and slidably connected with an inverted The T-shaped scraper 22, the upper and lower ends of the straight rod of the inverted T-shaped scraper 22 are respectively provided with horizontal holes 30, the outer end of the protrusion 31 is fixedly connected with the fourth spring 33, and the outer end of the fourth spring 33 is fixedly connected with the third pin 32 , the third pin 32 runs through the projection 31 and is fitted and slidably connected to the horizontal hole 30, the length of the cross bar of the inverted T-shaped scraper 22 is the radius length of the grinding disc 19, and the radius length of the grinding disc 19 is the same as the radius length of the crushing groove 5 When the third p...

Embodiment 3

[0037] Such as Figure 1-7 As shown, the powder scraping structure includes an L-shaped scraper 20, a transverse groove 21, a straight plate 27, a third spring 28 and a second pin 29, the F-shaped frame 7 and the grinding cylinder 6 are provided with a transverse groove 21, and the transverse groove 21 of the F-shaped frame 7 The left and right ends of the groove 21 are respectively fixedly connected with a straight plate 27, and the inside of the horizontal groove 21 is fitted and slidably connected with an L-shaped scraper 20, and the rear side wall of the L-shaped scraper 20 is fixedly connected with a third spring 28, and the outer end of the third spring 28 is fixed. Connected with the second pin 29, the second pin 29 runs through the socket of the L-shaped scraper 20 and the straight plate 27 to fit and slide. The plate 20 is flush with the left side inner wall of the crushing tank 5, and when the second bolt 29 is connected with the straight plate 27 at the right end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com