Chemical raw material sifting device for cosmetic production

A technology of chemical raw materials and cosmetics, applied in grain processing, centrifuges, etc., can solve the problems of resource waste and increase the production cost of cosmetics, and achieve the effects of saving production costs, simplifying the collection steps, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

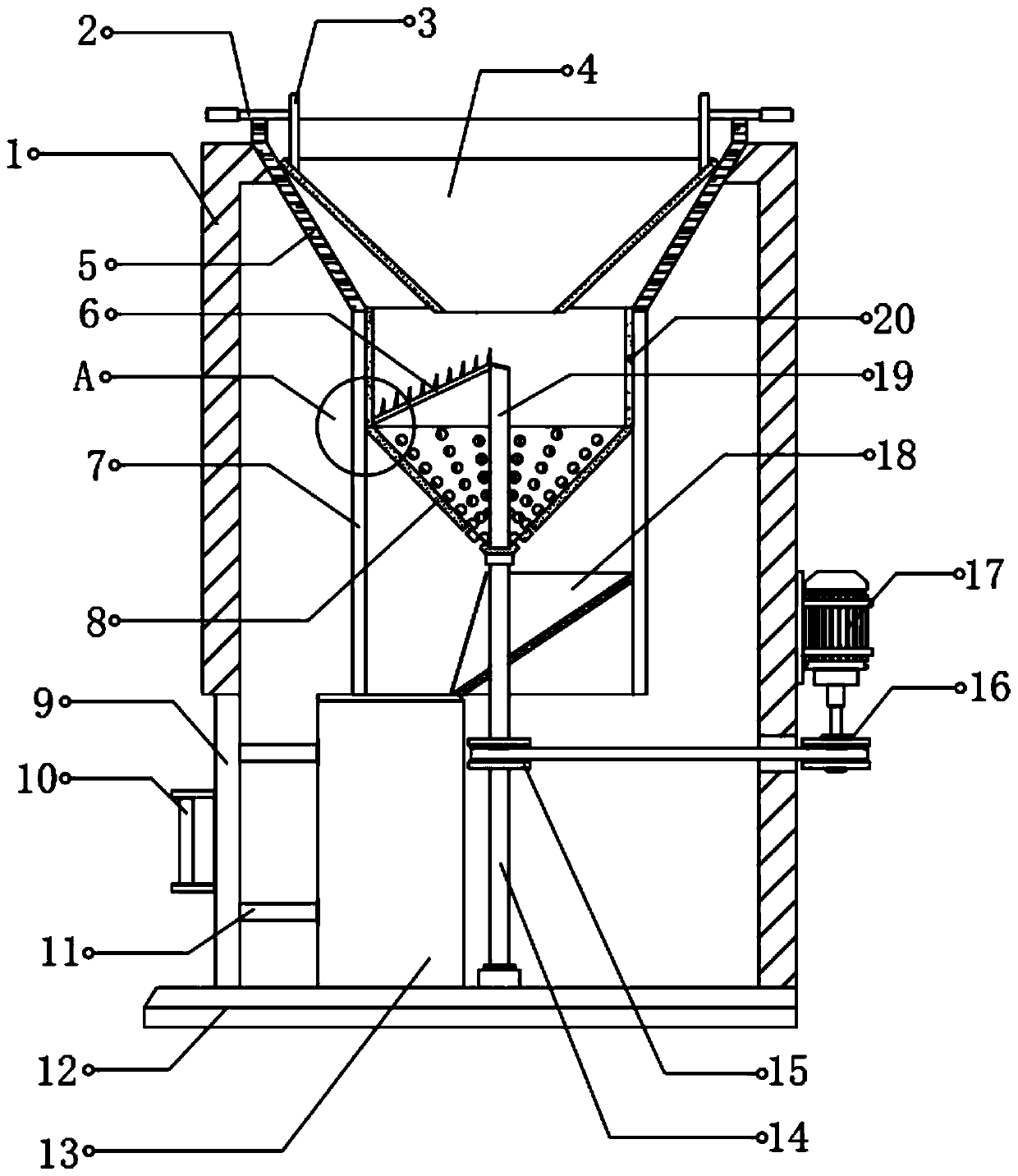

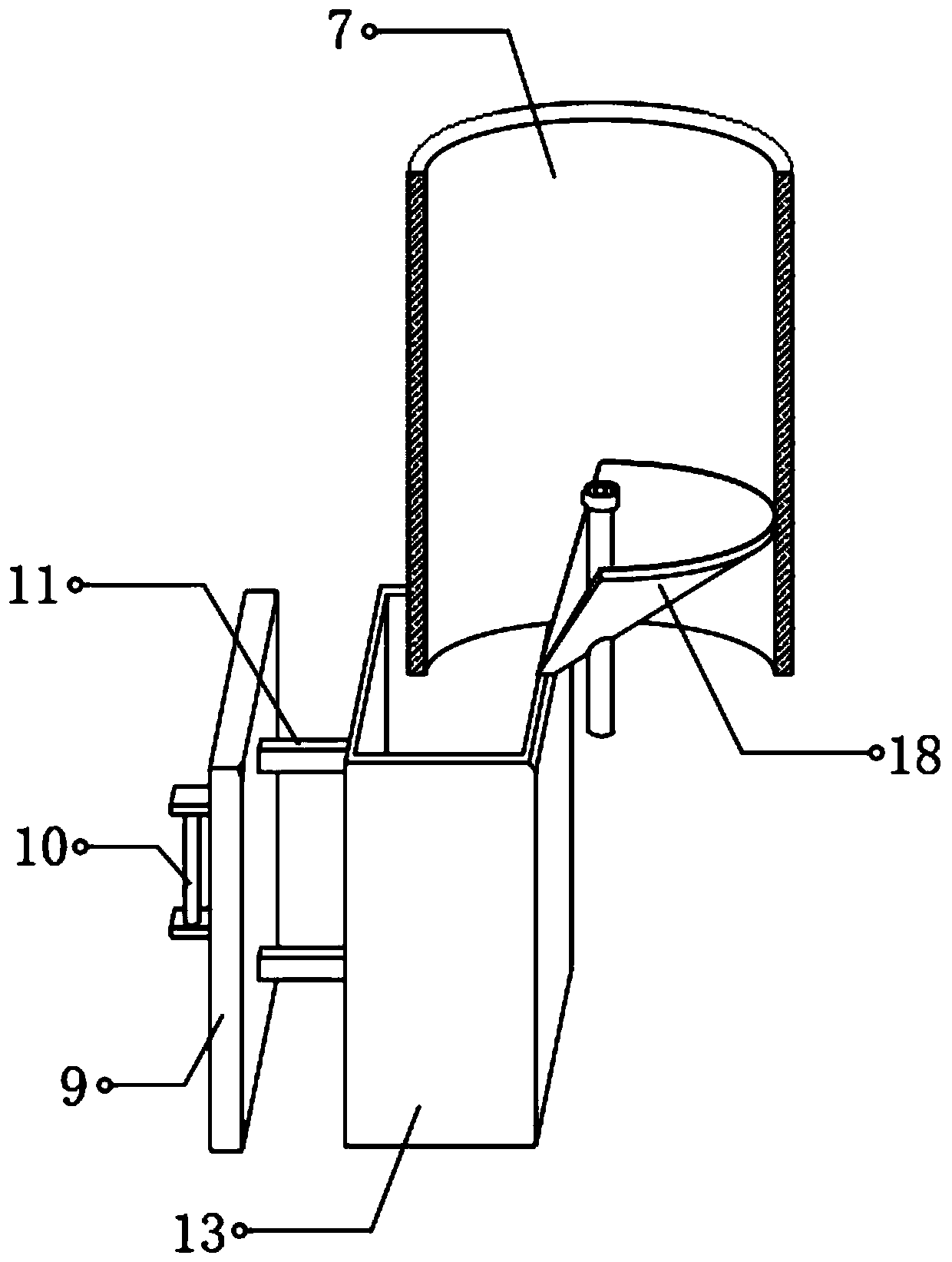

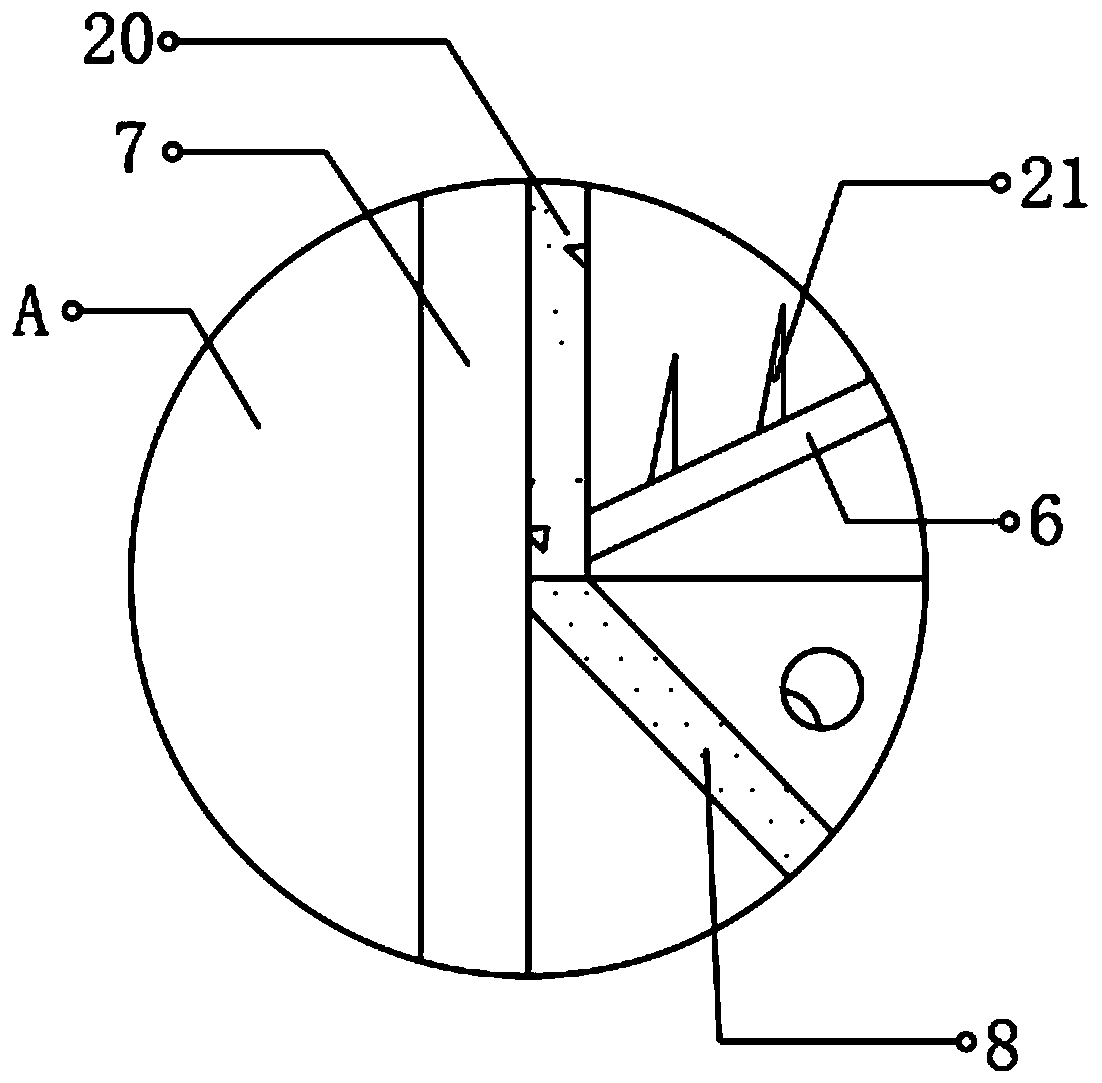

[0031] refer to Figure 1-3 , a chemical raw material powder sifting device for cosmetics production, comprising a base 12, the top of the base 12 is fixedly connected with a box body 1, and the middle position of the top of the box body 1 is fixedly connected with a fixed cylinder 5, and the inside of the fixed cylinder 5 is clamped with a The lower hopper 4, and the bottom of the fixed cylinder 5 is welded with a screening cylinder 7, the middle part of the outer wall of the box body 1 is fixedly connected with a motor 17, and the output end of the motor 17 is connected with a transmission rod 19, and the middle part of the transmission rod 19 is fixed. A sieve bucket 8 is connected, and the body of the sieve bucket 8 is provided with evenly distributed sieve holes. The top circumference of the sieve bucket 8 is welded with a material guide cylinder 20, and the outer diameter of the material guide cylinder 20 is smaller than the inner diameter of the sieve cylinder 7. The to...

Embodiment 2

[0040] refer to Figure 4-5 , a chemical raw material sieving device for cosmetic production. Compared with Embodiment 1, the inner wall of the bottom of the lower hopper 4 is welded with two fixed rods 22, and the same windproof bucket is welded between the two fixed rods 22. 23. The windproof bucket 23 is set in a conical shape, and the apex of the windproof bucket 23 is located inside the lower hopper 4 , and the outer diameter of the bottom of the windproof bucket 23 is larger than the inner diameter of the bottom of the lower hopper 4 .

[0041] Working principle: During the feeding process, the raw material falls from the gap between the windproof bucket 23 and the lower hopper 4. The windproof bucket 23 can initially impact the agglomerates in the raw material to optimize the effect of agglomeration splitting. At the same time, the windproof bucket 23 can also Effectively prevent external airflow from interfering with the internal space of the screening cylinder 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com