Annular part shaping device

A shaping device and a ring-shaped technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficult to achieve shaping tools, large sintering shrinkage, low work efficiency, etc., achieve a compact overall structure, and solve out-of-roundness Problems, the effect of easy disassembly and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

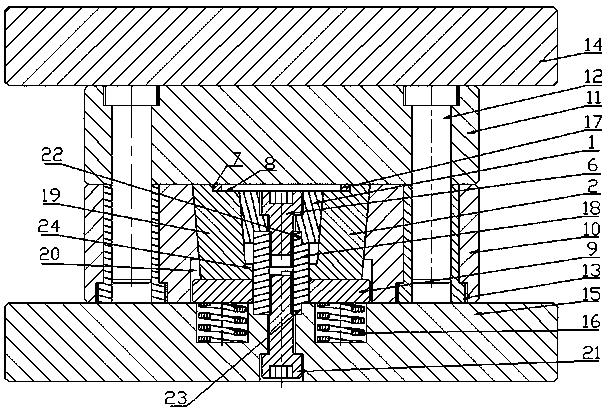

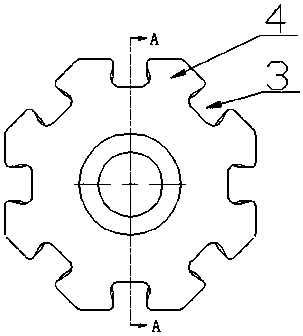

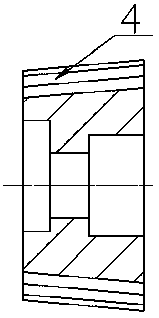

[0021] Embodiment 1: as figure 1 -shown in 4, a kind of annular part shaping device, it comprises base plate 15 and the lower mold base 10 that is fixedly arranged on the base plate 15, also includes the inner slide block 2 that is arranged on the lower mold base 10 and is the truncated circular platform shape The inner slider shovel base 1, the inner slider shovel base 1 is fixedly connected with the base plate 15; the outer circumference of the inner slider shovel base 1 is provided with a number of shovel base guides 3 and the number of inner sliders corresponding to the shovel base guide 3 2. The inner slider 2 reciprocates in the lower mold base 10 under the guidance of the shovel base guide path 3; the lower mold base 10 is provided with an inner slider reset mechanism; the inner side of the top of the inner slider 2 is provided with a concave step Shape shaping work surface, step shape shaping work surface comprises facade 7 and workpiece bearing surface 8, and the dist...

Embodiment 2

[0034] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that the direction in which the inner slider 2 moves along the shovel base guide path 3 and the central axis of the inner slider shovel base 1 include an angle of 15°. Spend. The façades 7 of the step-shaped plastic working surfaces on all the inner sliders 2 are assembled into a ring shape, and its roundness is 0.03mm.

[0035] The plastic product in this embodiment is a single product of a managed stop gasket. Use a surveying instrument to measure the roundness and flatness. The roundness before shaping is 0.8mm. Place the managed stop gasket on the workpiece bearing surface 8 Above, through the uniform and stable extrusion of the upper template 11 and the lower mold base 10, the hosting stop gasket is extruded and shaped, and the roundness of the hosting stop gasket after shaping is 0.09mm, and the flatness is 0.04mm.

Embodiment 3

[0037] The shaping product this time is a batch product of managed stop gaskets, the material is stainless steel, and the number of samples is 36 pieces. The roundness and flatness before shaping are shown in the table below. After assembling, it is in the shape of a ring with a roundness of 0.03mm. Place the managed stop gasket on the workpiece bearing surface 8 of the step-shaped plastic working surface, and squeeze it evenly and stably through the upper template 11 and the lower mold base 10. Squeeze and reshape the managed stop gasket, use a surveying instrument to measure the roundness data and flatness data after the managed stop gasket is reshaped, and the obtained data are as follows: (unit: mm)

[0038]

[0039] The results show that the roundness of the products after shaping is within 0.1mm, and the flatness is within 0.05mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com