Process for manufacturing technical wood veneer overlaid surfaces

A technical veneer and production technology, which is applied in the production process of technical veneer veneers, can solve the problems of undisclosed, easy-to-bubble, easy-to-bubble wear-resistant layer, etc., to improve resource utilization and ensure adhesion Intensity, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0018] Example.

[0019] The embodiment of the present invention is a manufacturing process of technical veneer veneer, the steps are as follows:

[0020] Step 1: Use the technology wood synthesis machine to turn the raw materials into technology wood cubes;

[0021] Step 2: Slicing the technological wood to make a technological veneer with a thickness of 35 wires;

[0022] Step 3: Put the melamine-impregnated paper on the technical veneer, and then send it into a heat press to press it into a technical veneer veneer.

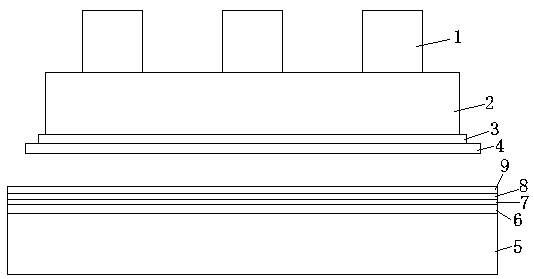

[0023] see figure 1 , in this embodiment, the hot press includes an upper pressing part 1, a heat conducting part 2 and a lower base 5, the upper pressing part 1 and the heat conducting part 2 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com