Positioning column of positioning mould for machining electronic components

A technology for positioning molds and electronic components, which is applied in the field of electronic component mold accessories, can solve the problems of damaged positioning columns, difficult installation and input, poor installation and fixing effects of positioning columns, etc., and achieves improved installation effects, increased friction, and installation and fixing effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

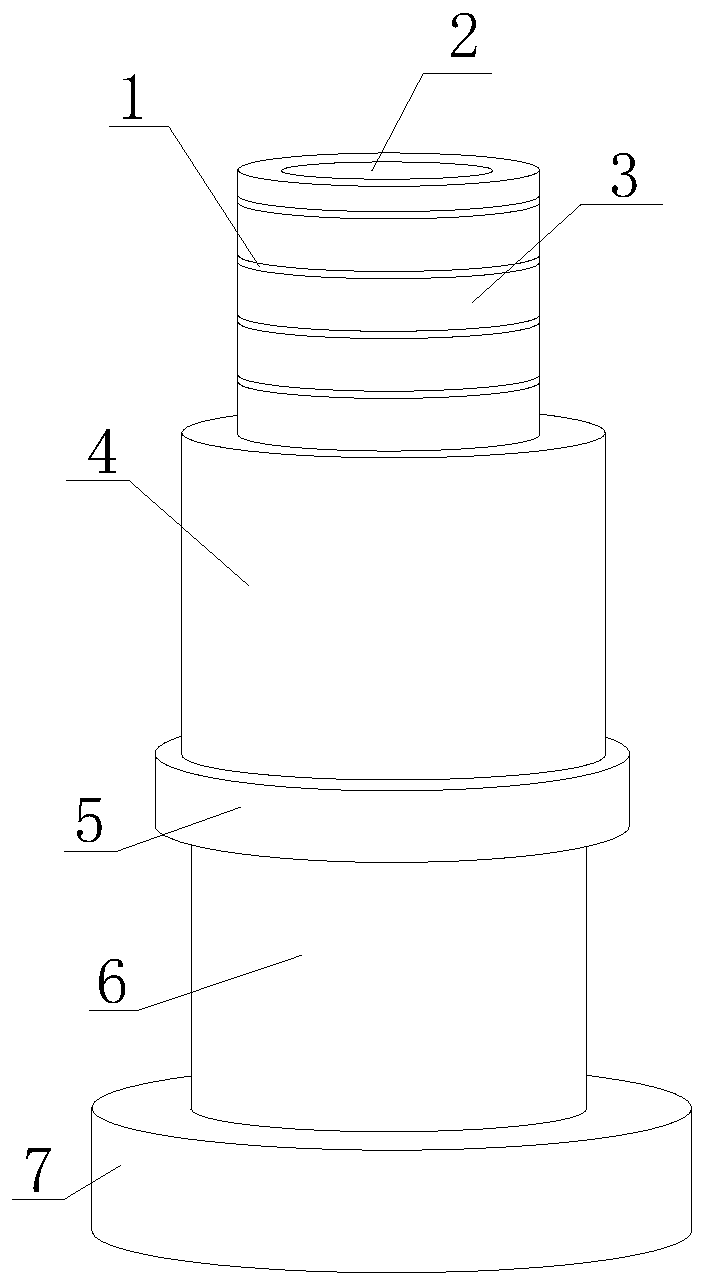

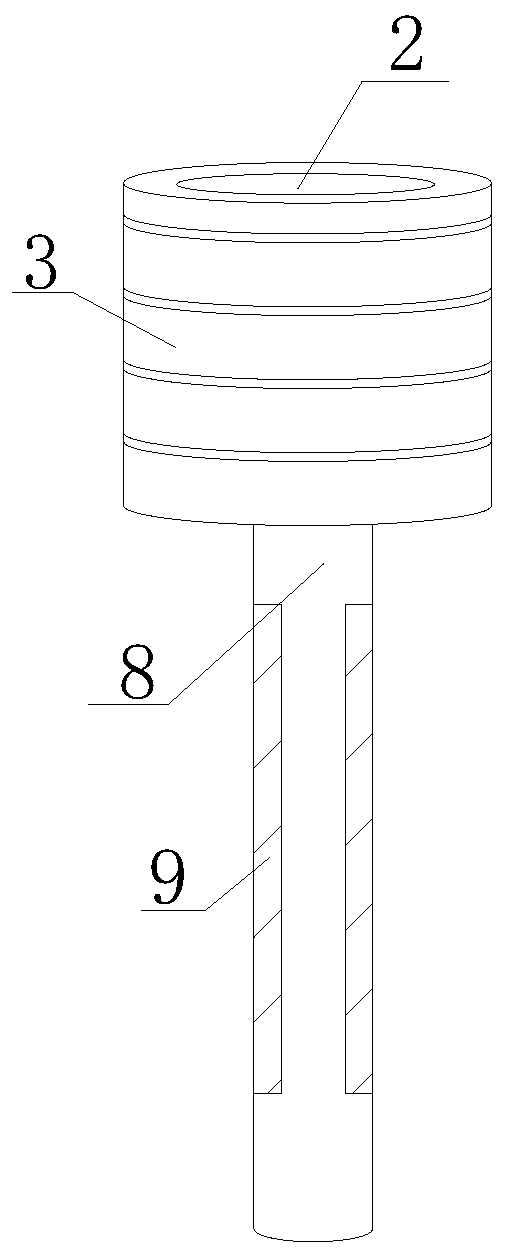

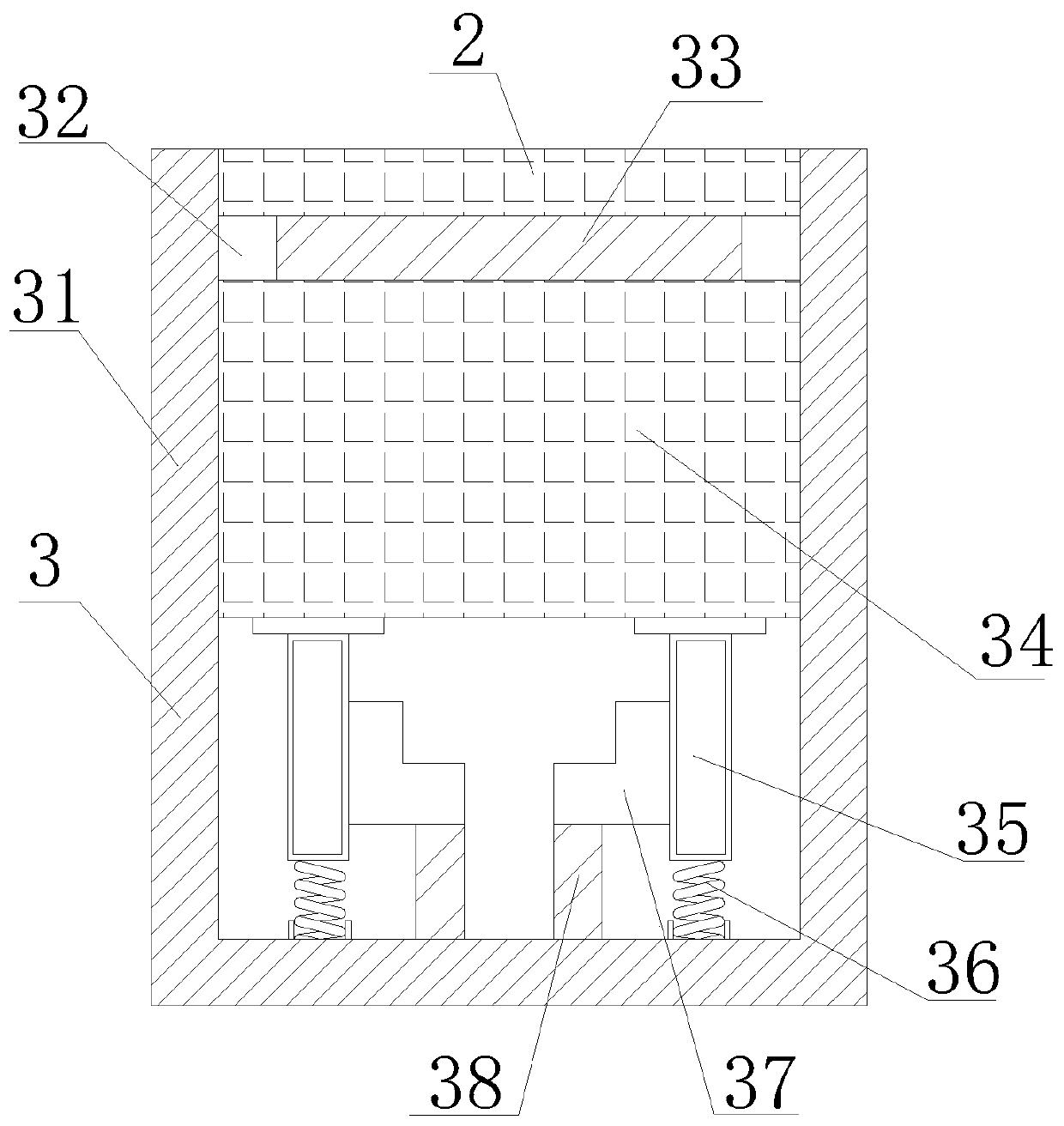

[0028] see figure 1 , figure 2 with Figure 4 , the present invention provides a positioning column of an electronic component processing positioning mold through improvement, including an annular rubber ring 1 and a snap-fit mechanism 10, the annular rubber ring 1 is nested on the top positioning column 3, and the bottom end of the top positioning column 3 is the same as The shaft center is equipped with an adjustment column 6, the top of the top positioning column 3 is equipped with an inner ring 2, the bottom of the top positioning column 3 is extended and installed inside the middle column 4, and the bottom edge of the middle column 4 is fixedly installed on the flat column 5. The rotation post 7 is installed at the bottom of the column 6, and the inner straight rod 8 is fastened at the bottom of the top positioning post 3, and the surface of the inner straight rod 8 is bonded with a rubber sheet 9.

[0029] see figure 1 with Figure 4 , the present invention provid...

Embodiment 2

[0034]The present invention provides a positioning column for processing and positioning molds for electronic components through improvement. The flat column 5 and the rotating column 7 are installed in parallel, and the support is stable in the vertical direction. The radius of the middle column 4 and the adjustment column 6 are equal. It is a flat sheet structure, which is convenient for supporting and setting. The annular rubber ring 1 is made of soft rubber, which is convenient to be inserted into the hole of the positioning mold, and then rebound and fastened in the hole by using rubber to embed in the hole.

[0035] The present invention provides a positioning column of an electronic component processing positioning mold through improvement, and the working principle is as follows;

[0036] First, put the rotating column 7 at the corresponding position of the positioning mold to prepare for the corresponding installation. When assembling the top positioning column 3 coaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com