Large 3D printer mechanism

A 3D printer, a large-scale technology, applied in the direction of additive processing, etc., can solve the problems of complex design structure, small printing area, and large occupied space, and achieve the effect of simple design structure, large printing area, and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

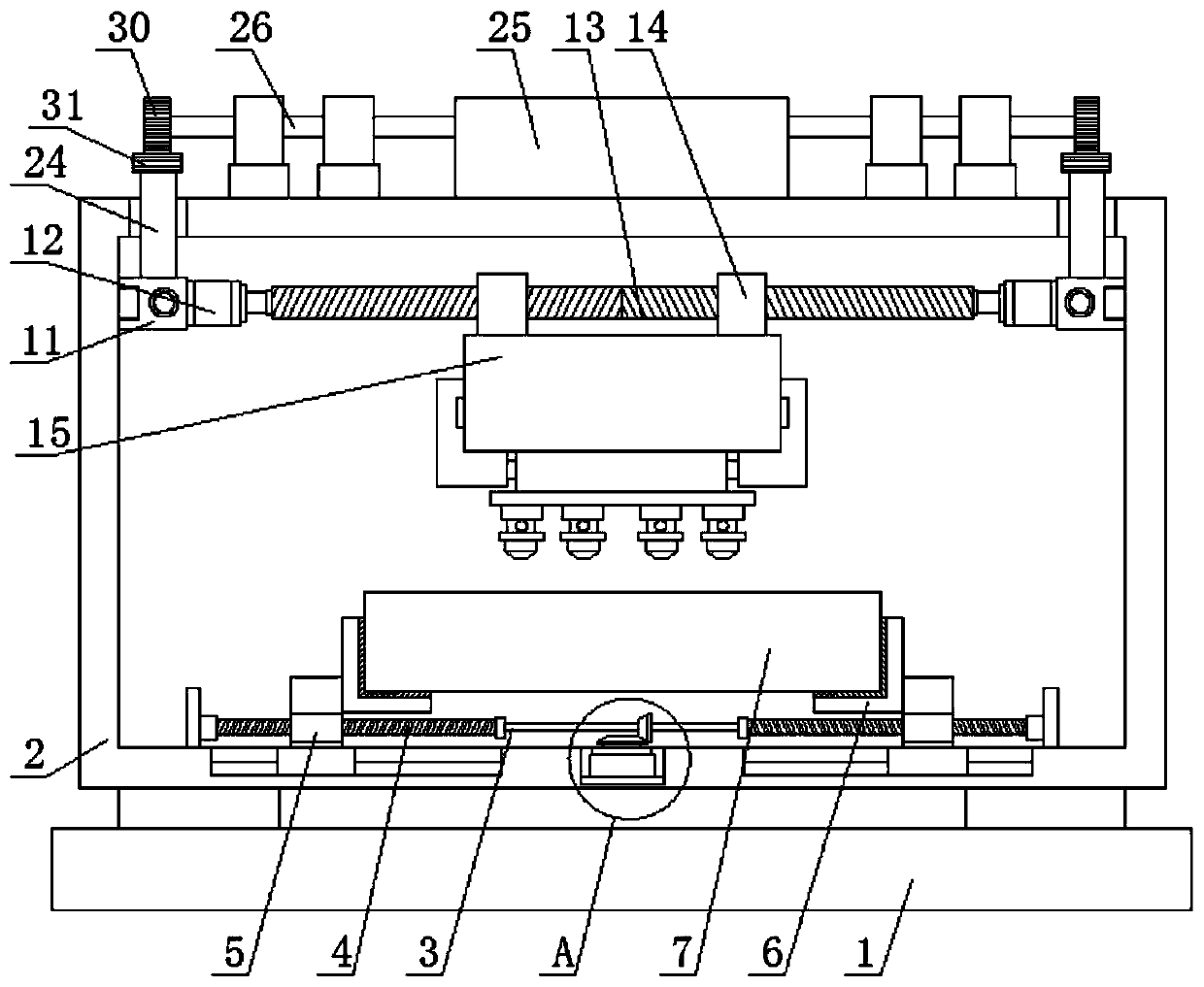

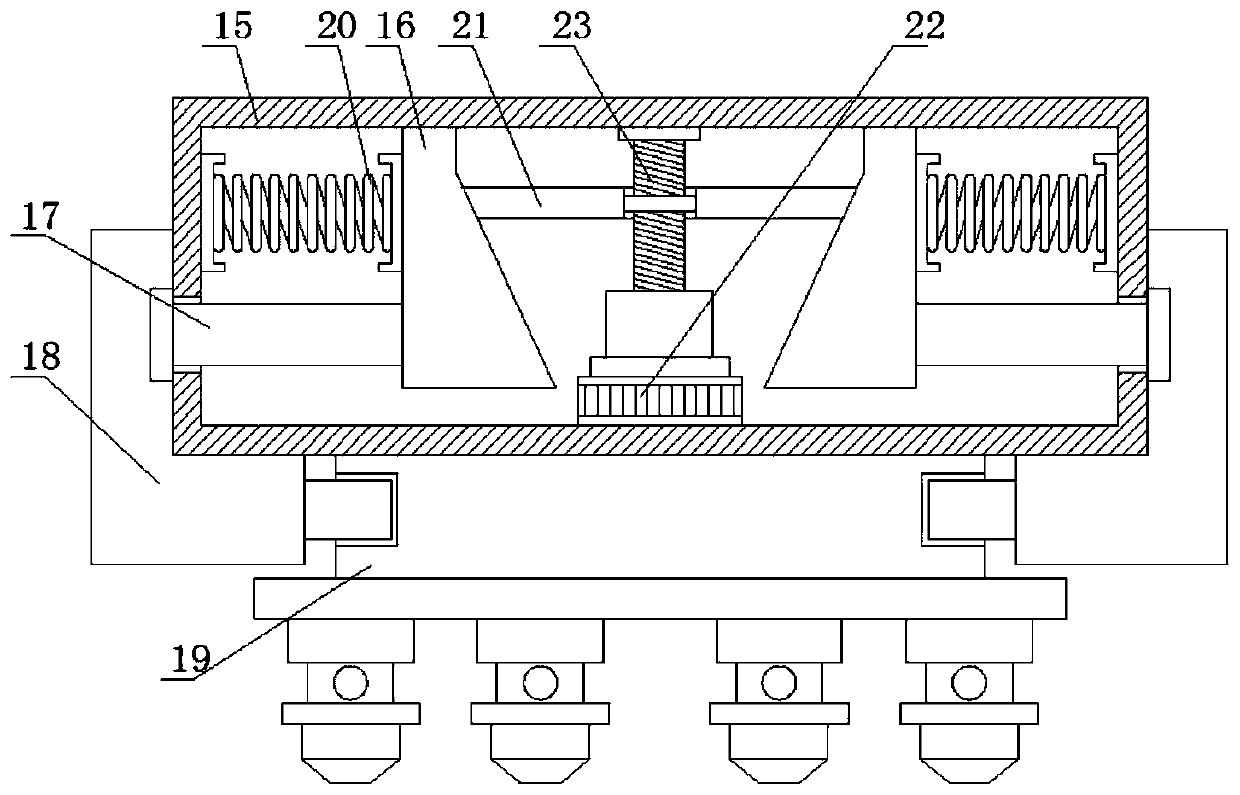

[0027] refer to Figure 1-5 , a large-scale 3D printer mechanism, including a base 1, a fixed frame 2 is fixedly installed on the top of the base 1, a clamping assembly is arranged on the fixed frame 2, and a workpiece 7 is clamped and fixed on the clamping assembly, and the fixed frame 2 A moving plate 11 is slidably connected to the inner walls on both sides, and a rotating motor 12 is fixedly installed on the side where the two moving plates 11 are close to each other, and the same screw rod 13 is fixedly installed on the output shafts of the two rotating motors 12, and the screw rod 13 is provided with two sections of thread that are arranged symmetrically, and two threaded blocks 14 that are arranged symmetrically are threaded on the screw mandrel 13, and the two sections of threads that are arranged symmetrically on the screw mandrel 13 run through the two threaded blocks 14 and connect with the threaded block respectively. 14 threaded connections, the bottom of the two ...

Embodiment 2

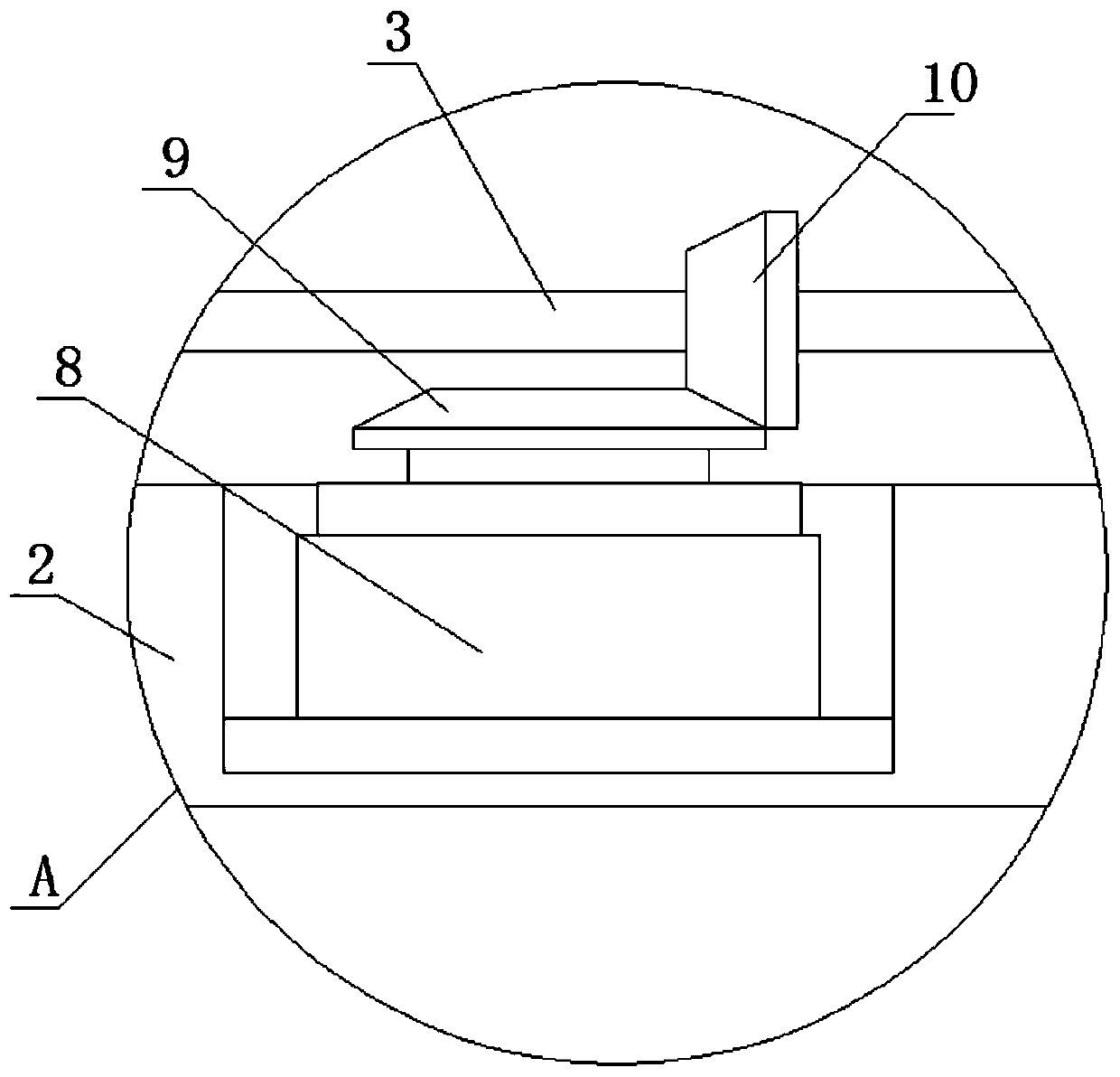

[0029]The clamping assembly includes a driving motor 8 fixedly installed on the fixed frame 2, a first bevel gear 9 is fixedly installed on the output shaft of the driving motor 8, two first screw rods 4 that are symmetrically arranged are rotated on the fixed frame 2, and The same rotating rod 3 is fixedly installed on the sides of the two first screw rods 4 close to each other, and the output shaft of the rotating rod 3 is fixedly installed with a second bevel gear 10, and the first bevel gear 9 and the second bevel gear 10 are meshed. Two sliding plates 5 arranged symmetrically are slidably connected on the fixed frame 2, and the two first screw rods 4 respectively pass through the two sliding plates 5 and are threadedly connected with the sliding plates 5, and the threads on the two first screw rods 4 are symmetrical. The sides of the two sliding plates 5 close to each other are fixedly equipped with L-shaped clamping plates 6, and the workpiece 7 is located between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com