Rail engineering vehicle transmission method

A technology for construction vehicles and rails, which is applied in the field of transmission control of dual-power source-driven rail construction vehicles to achieve the effects of reducing intermediate energy conversion points, reducing pipeline risk points, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

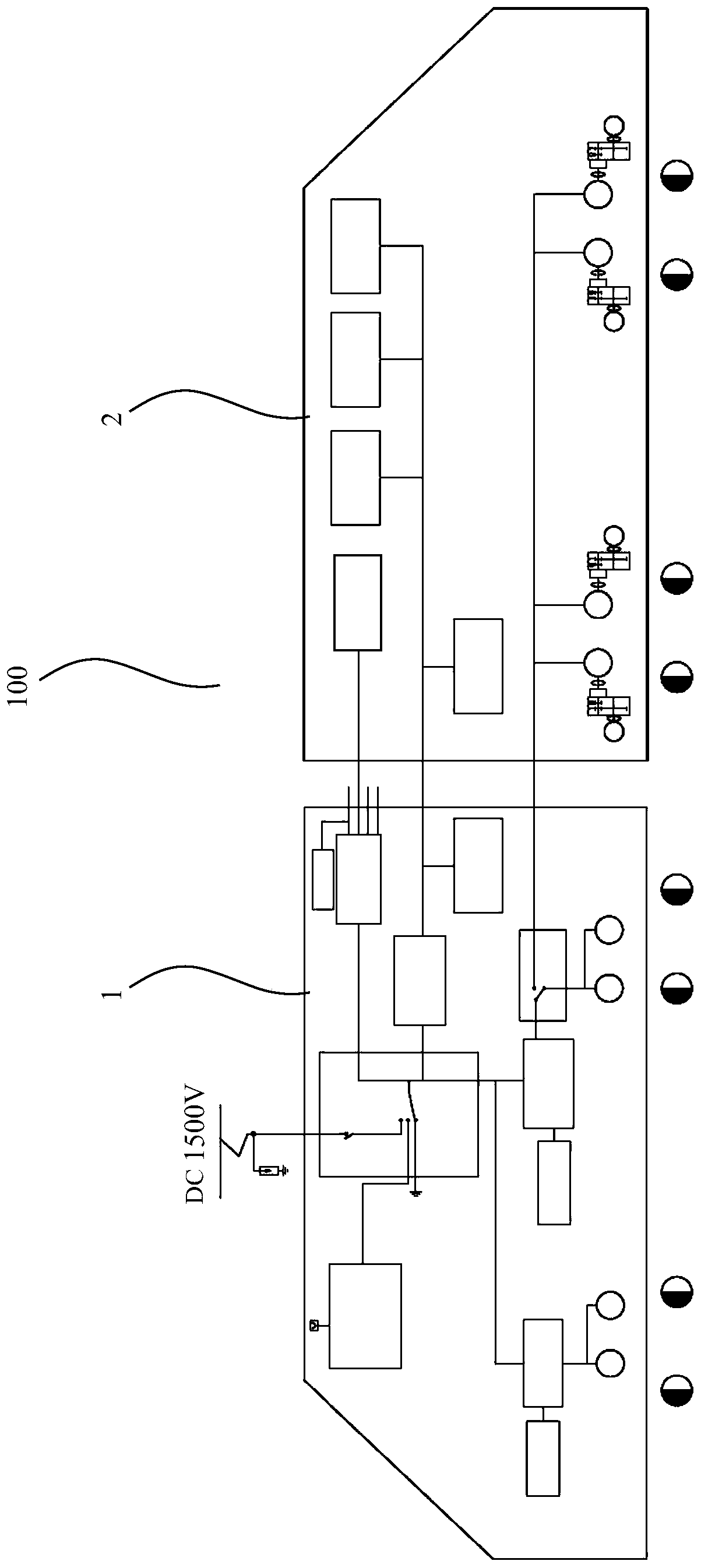

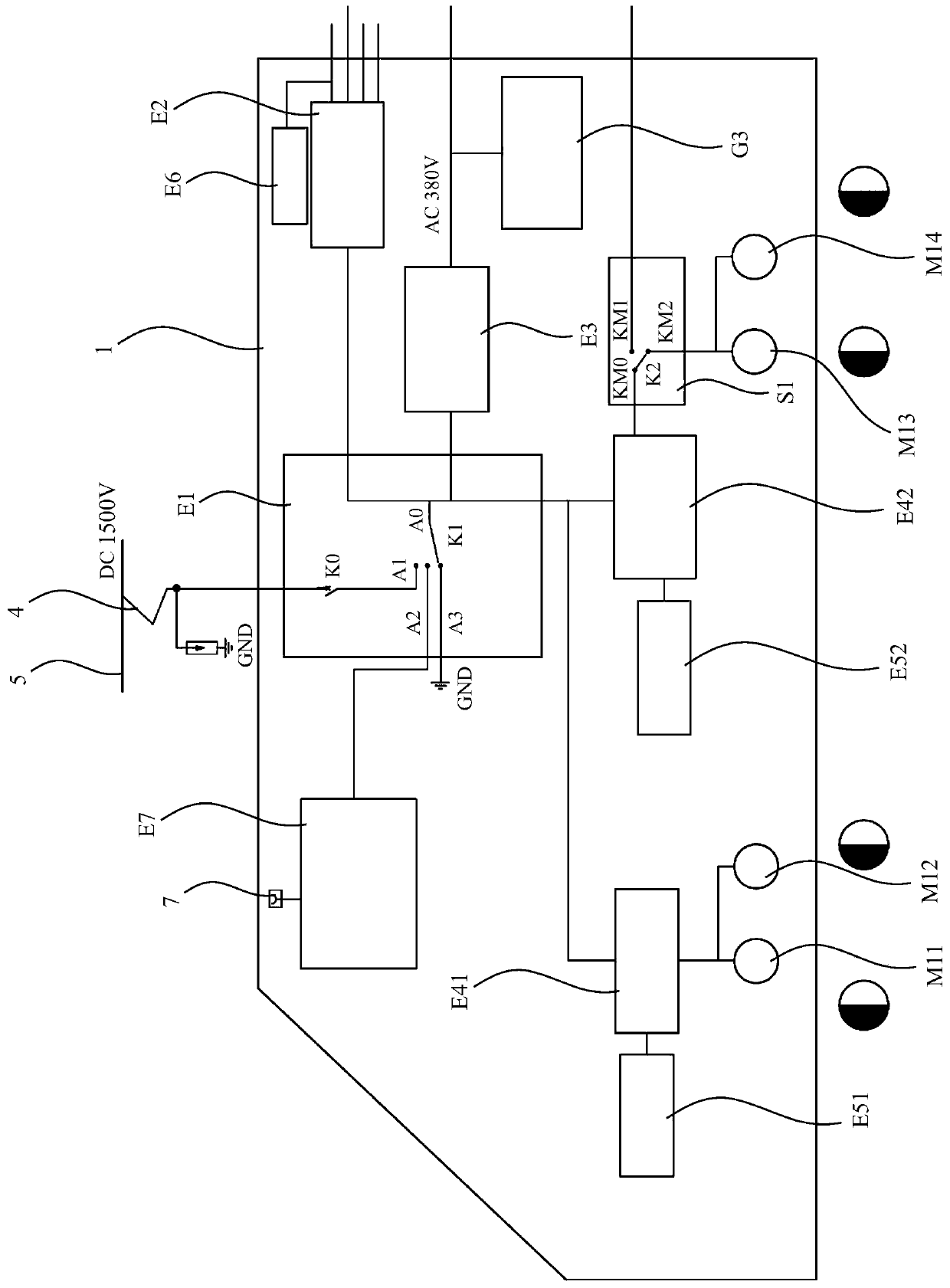

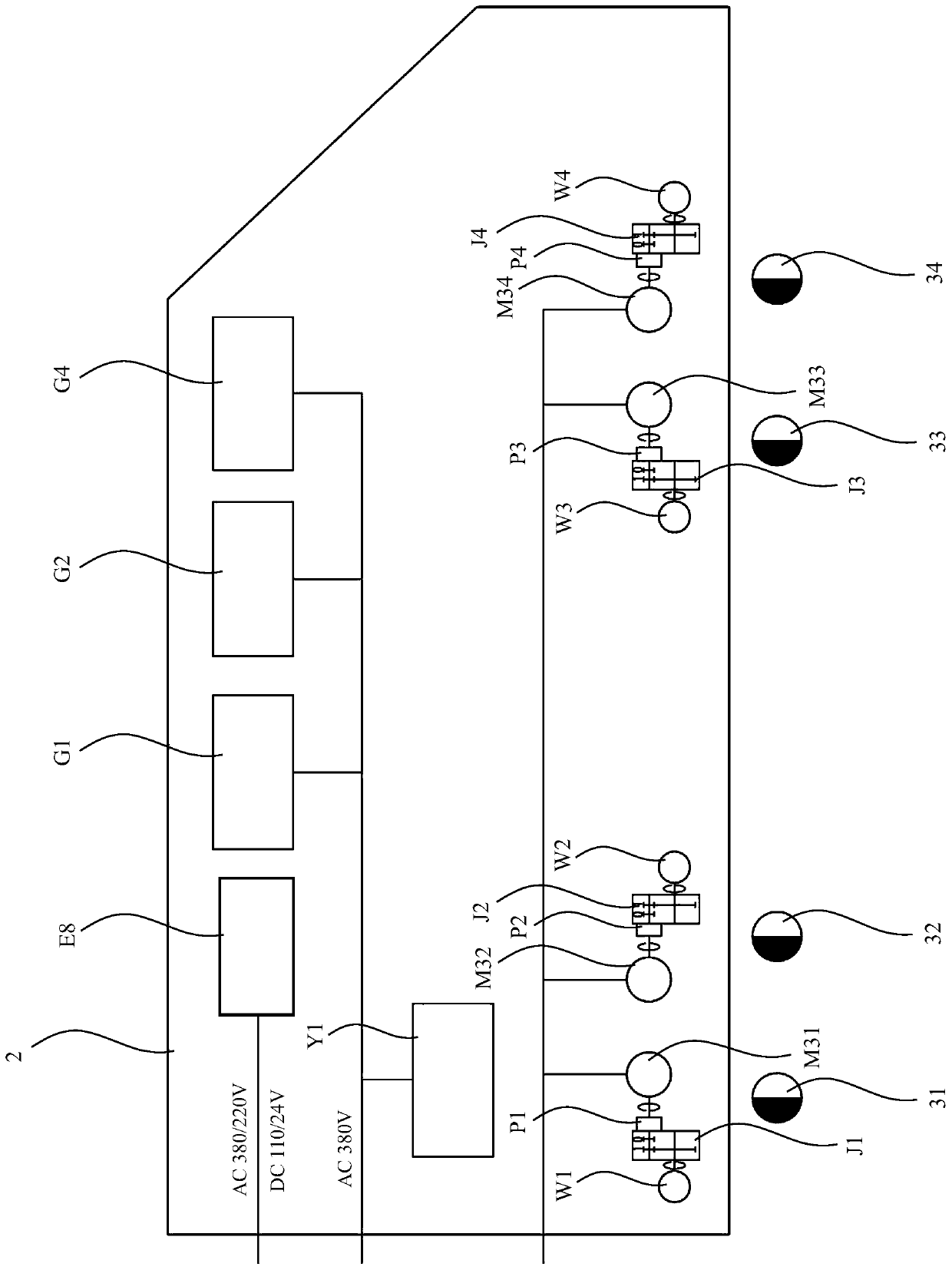

[0053] as attached figure 1 As shown, a kind of embodiment of the track engineering vehicle transmission system based on the method of the present invention, the track engineering vehicle 100 includes a power car 1 and a working vehicle 2, and the power car 1 is responsible for providing train power, high-speed running and low-speed running power source, and operating Car 2 is responsible for operating functions and realizing low and constant speed running. The transmission system of rail engineering vehicles specifically includes: the vehicle power supply system and high-speed running system arranged on the power car 1, the low-speed running system arranged on the working car 2, and the operating system partially or completely arranged on the working car 2. The vehicle power supply system provides power for the operating system, and can optionally provide power for the high-speed running system or the low-speed running system. The high-speed running system adopts electric dr...

Embodiment 2

[0072] An embodiment of the transmission method of a rail engineering vehicle of the present invention, the rail engineering vehicle 100 includes a power vehicle 1 and a working vehicle 2, and the power transmission method specifically includes the following steps:

[0073] A) Arrange the vehicle power supply system and high-speed running system on the power vehicle 1, and arrange the low-speed running system on the work vehicle 2; arrange it separately on the work vehicle 2, or arrange the operation system on the power vehicle 1 and the work vehicle 2;

[0074] B) The vehicle power supply system provides power for the operating system, and can optionally provide power for the high-speed running system or low-speed running system;

[0075] C) Realize high-speed running through the high-speed running system, which adopts electric drive traction to realize the running speed of rail engineering vehicles from 0 to 80km / h and the speed control accuracy of less than 0.5km / h;

[0076...

Embodiment 3

[0102] as attached Figure 4 to attach Figure 6 As shown, a rail milling car based on the transmission method of rail engineering vehicles described in Embodiment 2 is composed of a power car 1 and an operating vehicle 2. The power car 1 is responsible for providing train power, high-speed running and low-speed running power source, and the working vehicle 2 Responsible for operating functions and realizing low and constant speed travel. Wherein, the power car 1 includes an electrical room 11 , an inspection room 12 and a scrap bin 13 . Inside the electrical room 11 are arranged a traction battery cabinet (corresponding to the traction battery E7) 101, a low-voltage control cabinet 102, a high-voltage cabinet (corresponding to the high-voltage box E1) 107 and a converter control cabinet 108. In the maintenance room 12 there are a maintenance platform 103 , a tool cabinet 104 and a brake control cabinet 109 . The scrap iron bin 13 is provided with a working power supply box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com