Power battery charging and heating loop, control method thereof and electric vehicle

A power battery and heating circuit technology, applied in electric vehicles, battery/fuel cell control devices, electric vehicle charging technology, etc., can solve problems such as easy arcing, faults, and impact on relay life, and achieve the effect of avoiding arcing phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

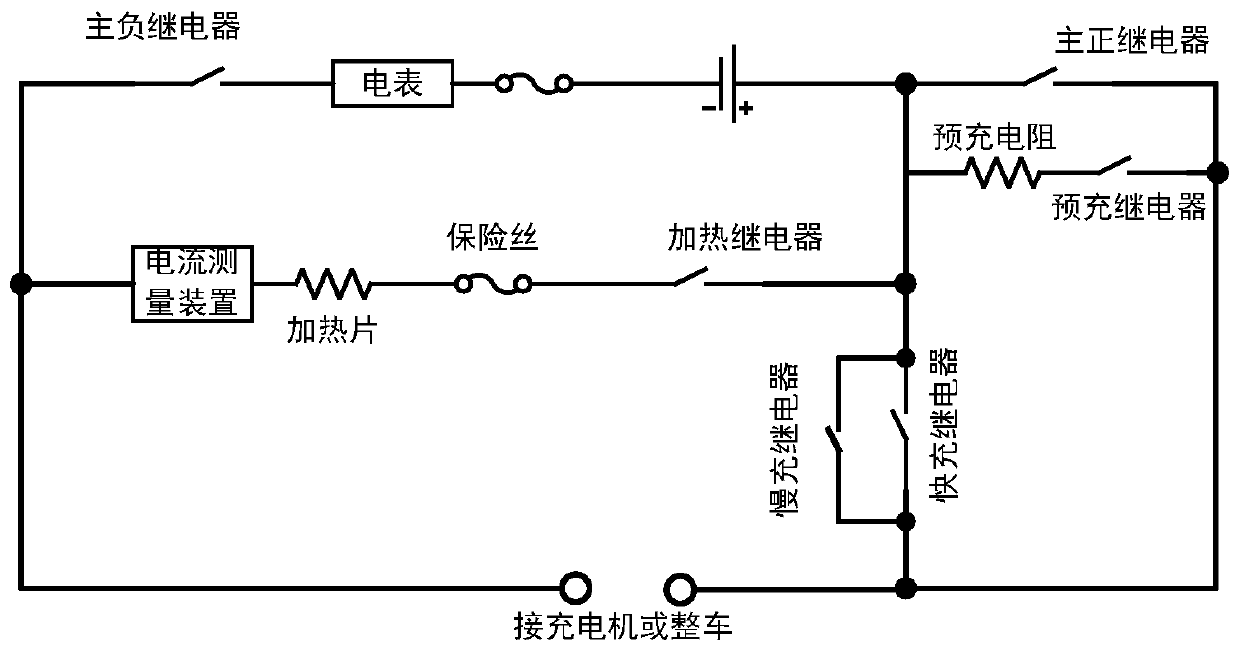

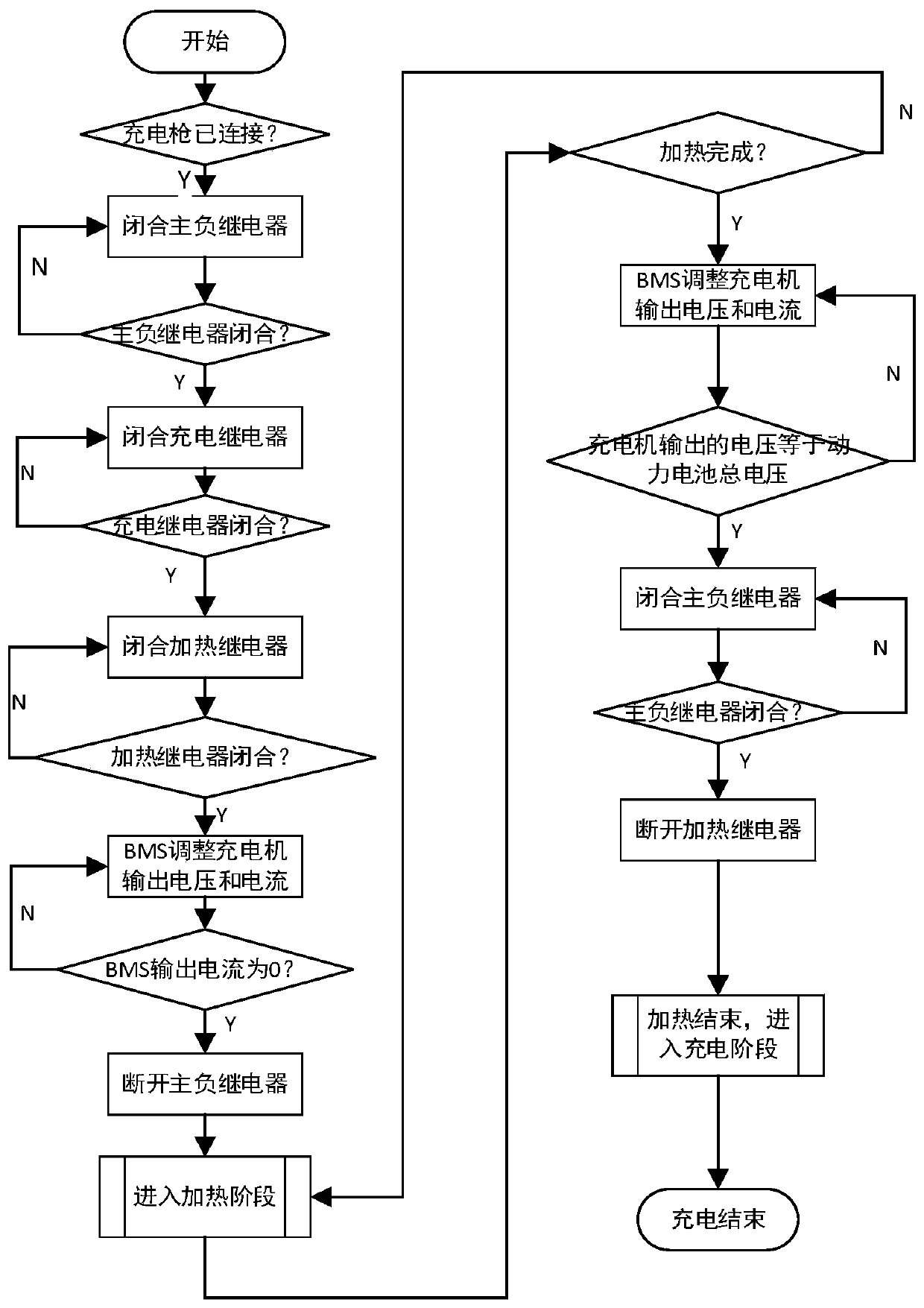

[0032] This example describes a figure 1 The control method of the power battery heating and charging circuit is shown. The heating and charging circuit of the power battery includes a power battery, a charger and a battery management system BMS, and the battery management system is used to collect the parameters and status of the power battery, and adjust the output voltage of the charger in real time according to the parameters and status of the power battery and current. A charging circuit is connected between the power battery and the charger, and the positive and negative poles of the charger are connected with a heating circuit; the charging circuit is controlled by a charging relay, a main negative relay, and the heating circuit includes a charging relay, a heating relay, and a current measuring device , fuse and heating device. The charging relay includes a fast charging relay and a slow charging relay, and the charging relay can be in the main positive circuit, or i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com