Ultra-long-distance large-volume aluminum oxide conveying method and system

An alumina, conveying technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of high renovation cost and construction cost, high cost, high terrain requirements, and achieve small external influence and strong stability. , Comprehensive cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

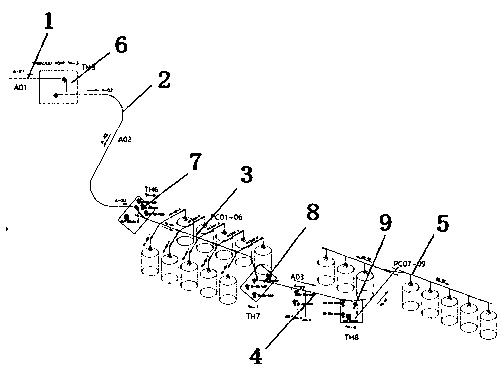

[0018] In a port in a certain country, the silo of an electrolytic aluminum plant is more than 3,000 meters away from the port. The terrain is complex, the heights are inconsistent, and there are many roads in the middle. If traditional railway or vehicle transportation is used, a special alumina powder needs to be built at the port. Storage yards and dedicated transportation routes require huge investment, occupy an area, have serious pollution, and are greatly affected by weather. Using the ultra-long-distance and large-capacity transportation method of alumina and the transportation system set up by this method, It occupies a small area, has low operation and maintenance costs, can realize large-volume transportation, is less affected by the external environment, and has no pollution.

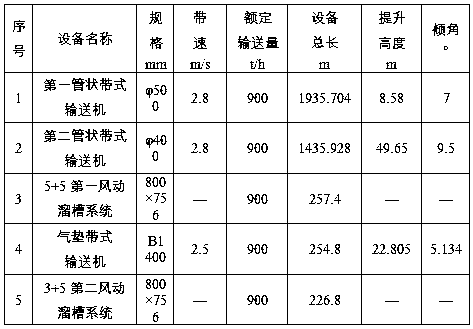

[0019] Specific programs such as figure 1 As shown, an ultra-long-distance and large-capacity transportation method for alumina, step 1), select two DG-type tubular belt conveyors, two sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com